Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

Summary Experience has taught me that it is essential to start with an accurate estimate of filament diameter, especially for long running jobs. I've also learned that the measurement size indicated on a purchased spool of filament is unlikely to be accurate. It is tedious, but I always measure every new spool of filament before loading it into my printer. This tool makes it easier to get an accurate measure.

7/20/15 Before I started using this tool, even my new TAZ 5 printer (.5 mm nozzle) would produce garbage. The first part of the job would look great, but about an hour and a half into it, the extrusion would fail, and I would get a lot of stringing and clogging. I can now run very long term jobs and get perfect prints with no clogging or stringing. I've got a 9.5 hour job running now. It is almost complete, and it looks excellent.

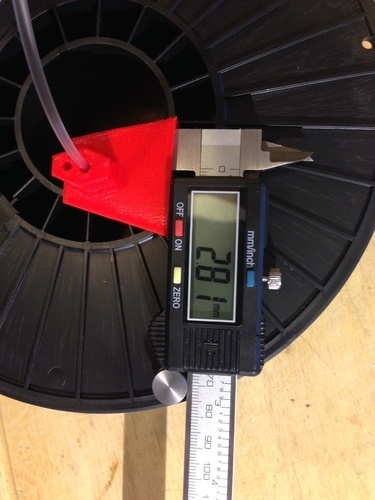

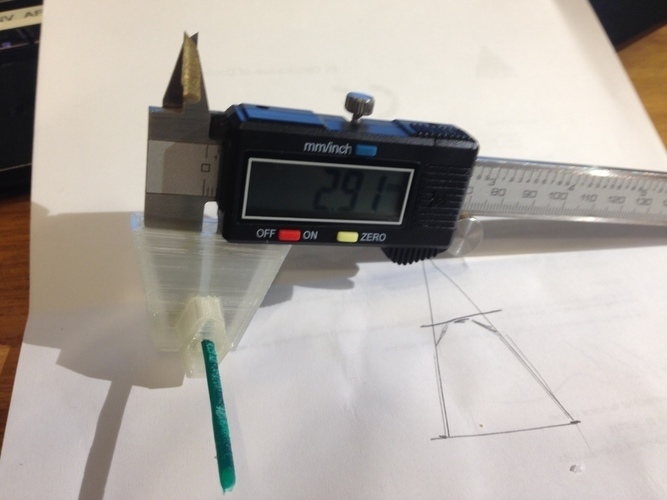

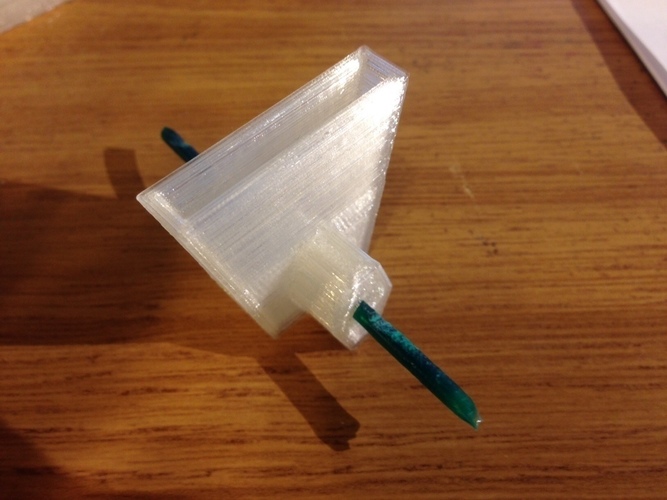

I noticed that when I measure the thickness of my filament, if it isn't exactly perpendicular to the measuring tool, I get inaccurate and varied measurements. This tool can hold the filament perpendicular while measuring. I made it with two holes so that both 1.75 and 3 mm filaments can be measured.

I've printed without accurate measurement, and experienced clogging, stringing, caking on the feed gear, and notches gouged in the filament.

1) It appears that if the filament diameter is estimated low, the pressure in the nozzle becomes too high, will cause excess extrusion, and clogging. I haven't experienced it, but from what I've read, this can also cause the plastic to ooze out the input.

2) If the estimate is high, then the further you get into a large print job, the greater the deficiency of filament. Initially, the job starts printing fine, but the deficiency is cumulative. A long running job will eventually not extrude much at all, leaving something that looks more like spiderweb than plastic.

In either case, if the feed stops, the extruder feed gear can gouge out a chunk of filament, and become caked with plastic chips. Until the plastic is cleaned off of the feed gear, it will slip against any new filament that is loaded.

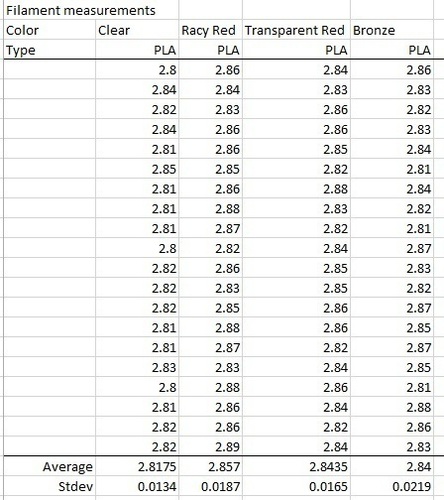

I take an average of 21 measurements, and enter the filament diameter up to 4 decimal places. If a measurement flips between numbers, I assume that the true value is between the numbers.

By calculating the standard deviation, I've noticed that some filaments are more consistent than others.

Comments