Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

Summary

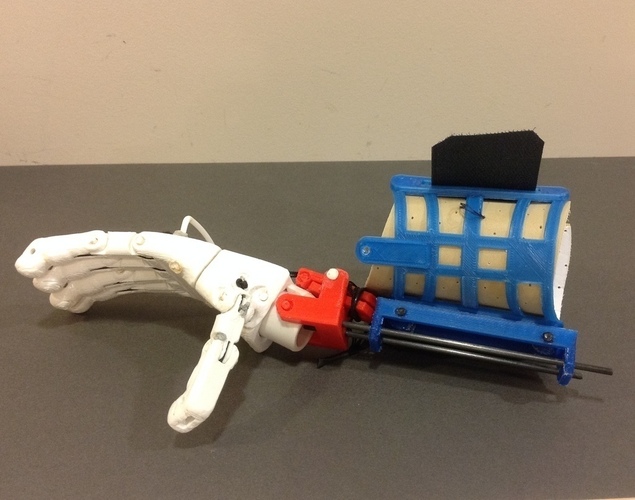

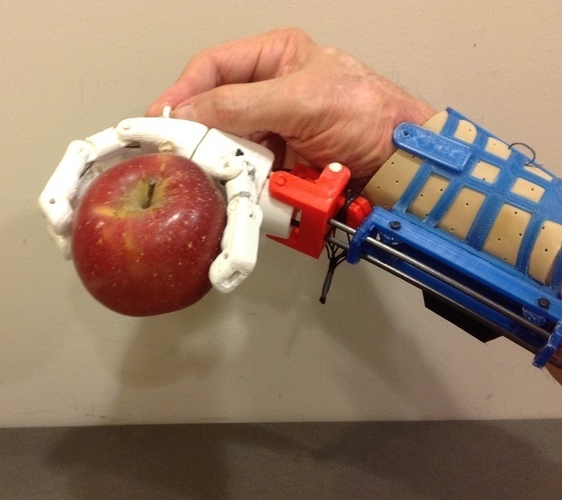

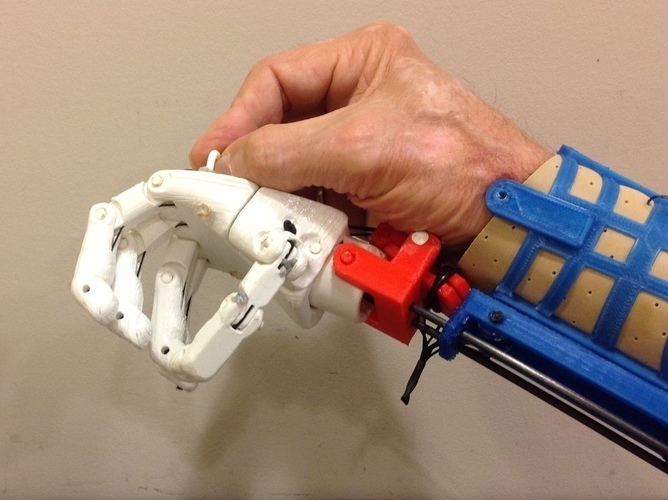

The Modular e-NABLE Research Platform (MeRP 1.0) is a modified wrist-actuated prosthetic hand that can be worn by able-bodied people for use in their day-to-day activities. This allows prosthetic hand designers to improve their designs by actually using the products they design. Designers can share the experience of people who will use products they create.

Note: This was an early design in my e-NABLE research and many elements of the design can be improved. It has recently evolved into the e-NABLE Prosthetic Emulator.

The MeRP 1.0 straps onto the user’s forearm with a “gauntlet” that supports a prosthetic hand below the user’s hand. The user actuates the fingers of the prosthetic by flexing his/her wrist which causes the prosthetic hand to move, and strings running through the prosthetic fingers like tendons cause them to create a grasping movement.

The modular nature of the MeRP 1.0 allows the user to try different designs of hands, fingers, thumbs, gauntlets and actuating mechanisms to evaluate the pros and cons of each design. For more information about the e-NABLE prosthetic hands that are created on 3D printers and provided to children (free of charge), see http://enablingthefuture.org/.

Credits:

A remix of https://www.youmagine.com/designs/rit-e-nable-arm-v0-43#!design-information. The MeRP 1.0 design was based on a prosthetic arm designed at Rochester Institute of Technology by e-NABLE volunteers and on other open-source designs shared within the e-NABLE community.

Instructions

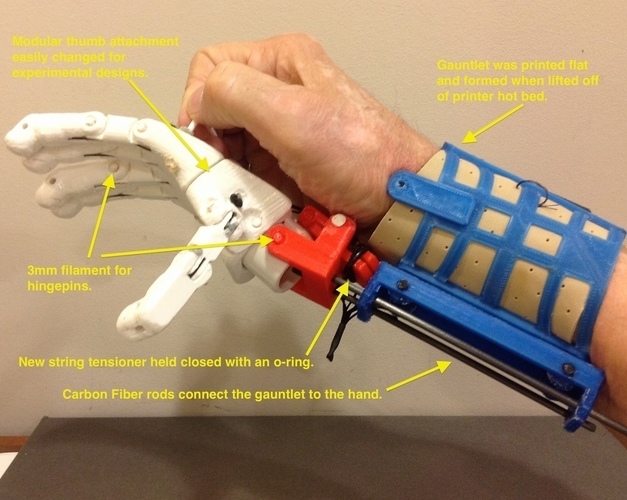

- Use 1/8 inch carbon fiber rod to connect the Gauntlet to the Hand. http://www.amazon.com/Carbon-F... (make sure you don’t order direct from China, as it may be on a slow boat and take a month).

- Print the Gauntlet halves in PLA flat on the printer hot bed (90C) and fold it around a form while it is still warm, right after it s taken off of the bed. I used an oval container from Crystal Light drink mix for a form.

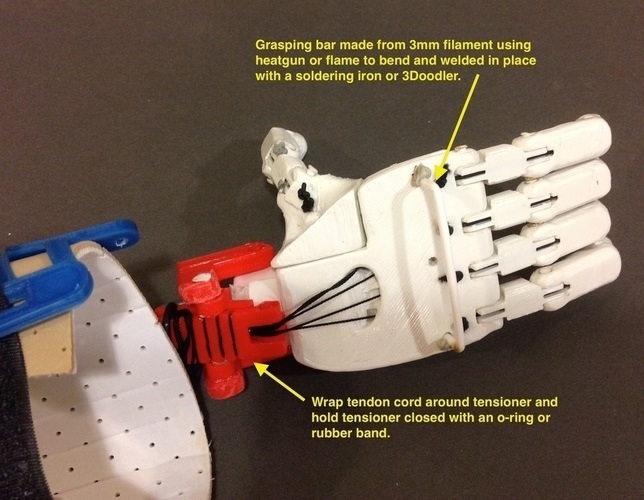

- Hinge pins are rivets that are made from 1/8 inch filament and melted on the end with a soldering iron. (Small $10 packs of 3mm filament sticks can be obtained from 3Doodler if your printer uses 1.75mm.)

- Grasping bar on the back of the hand is also fabricated from 3mm filament. Bend corners with heat-gun or flame and weld in place with a soldering iron or 3Doodler.

- The thumb module is attached to the palm module with pins that are also made from 1/8 inch filament.

Comments