Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

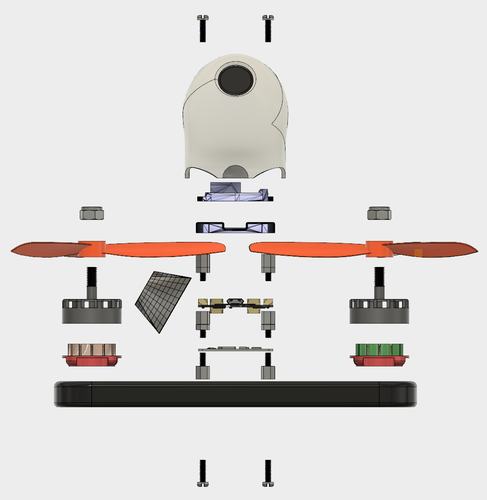

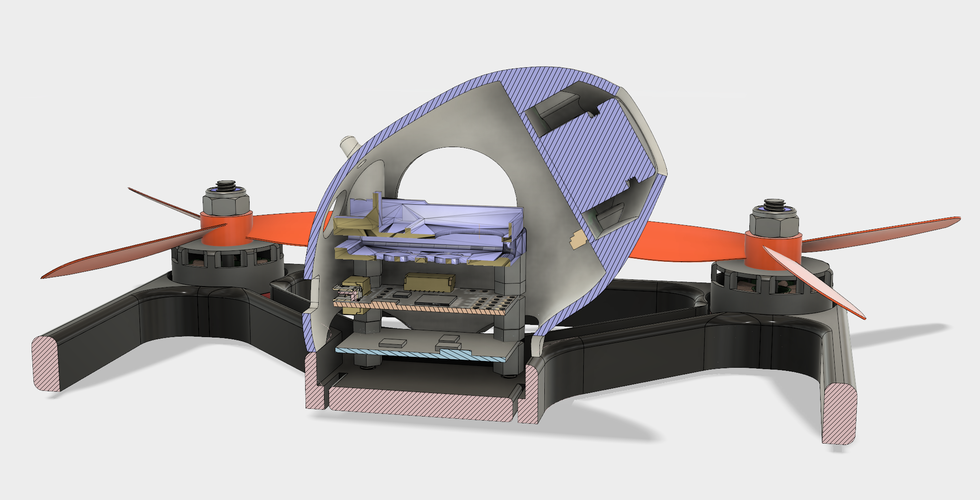

This is a frame for a freestyle/racing sized quadcopter. It is designed to be an insanely fast, lightweigth and aerodynamic frame, while still enduring hard crashes. The frame can be printed without support on 200mm*200mm printbeds. It fits standard 2205/2204 motors and electronics with 30.5mm mounting hole spacing, making it compatible with most racing quadcopter equipment.

Example build:

This is the parts I would recommend if you want to enter the world of miniquads on a budget.

Motors: BR2205-2300KV

ESCs: RS20A-V2

Flight controller: Naze 32

Propellers:

FPV Gear:

You can fly the quadcopter without the fpv gear, but it is highly recommended to use it.

Camera: I have designed the pod for the RunCam PZ0420M camera.

VTX:

Eachine ET526 5.8G 40CH 25mW200mW600mW Switchable FPV Transmitter

Antenna: Aomway 5.8GHz FPV 4 Leaf Clover AV Transmission RHCP Antenna

You'll also need a transmitter, receiver, batteries and soldering equipment. You can read more about parts and multicopters in general here.

For a transmitter I would recommend getting a Taranis X9D PLUS, it's a fantastic transmitter that you can use for years. If you have a tight budget, get the FS i6, but you will most likely want something better pretty soon.

4s batteries are absolutely recommended, the Infinity Graphene are great and cheap.

Printing

Baseframe

This part needs to be printed in a strong and rigid material. While PLA will work, it’s brittle and will snap on very hard crashes, but otherwise the quadcopter will fly well. ABS, what I have used, works really well, other materials worth considering are PETG, nylon or polycarbonate if you can print those.

If you are printing ABS, acetone smoothing is highly recommendable. It increases the strengthening of layer bonds via the reduction of surface stress concentrations.

I didn’t have a large enough container to smooth the frame, so I painted on a mixture of acetone and ABS plastic.

I used 95% triangular infill, with five shells, top and bottom layers for maximum strength.

Aeoropod

This part would ideally be printed with a flexible material like TPU or TPE, but I don’t have that and printed it in PLA. That has worked well so far. You need support for the screw holders, and these needs to be added manually to not get support structure all over the part, as this is not needed.

The x4r mount was remixed from Frsky D4r-II tx board stack mount

The ET526 was remixed from QAV210 Lisam TX Eachine ET526 holder

If you have any questions I am more than happy to answer them.

Comments