Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

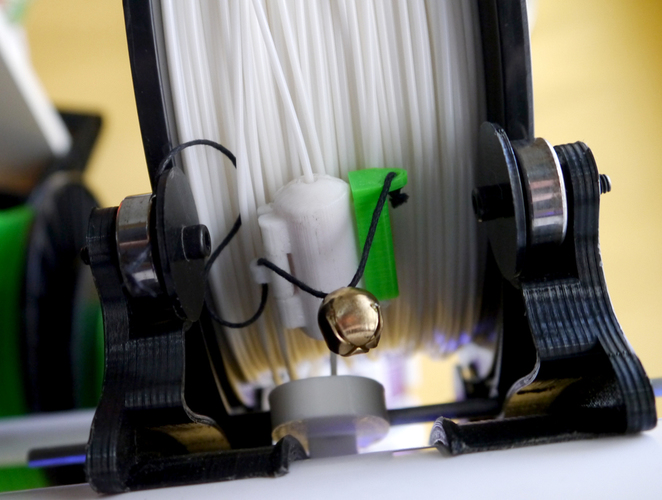

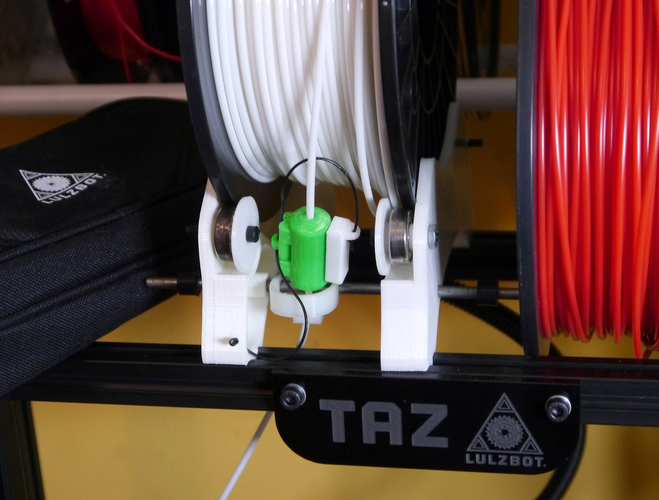

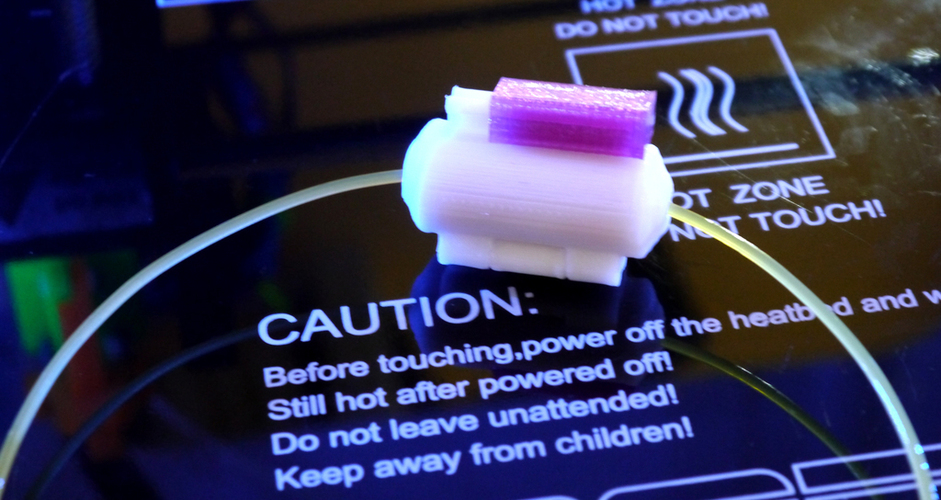

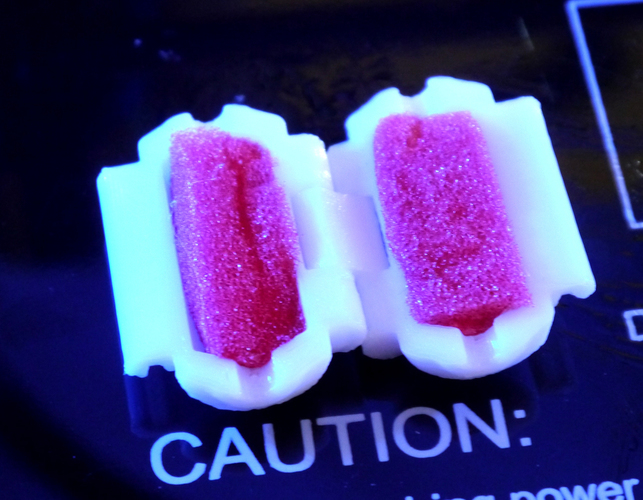

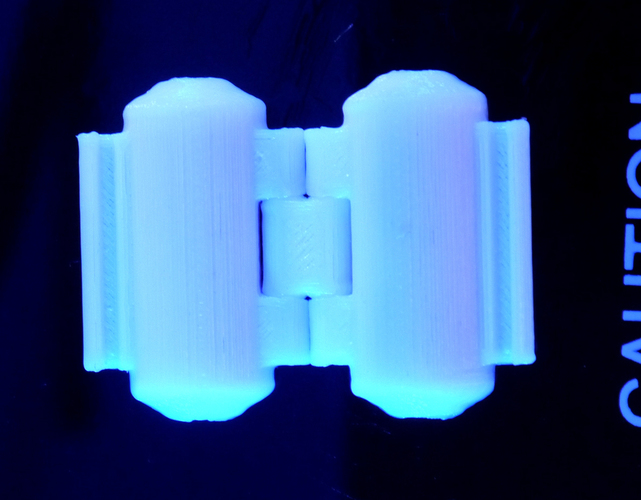

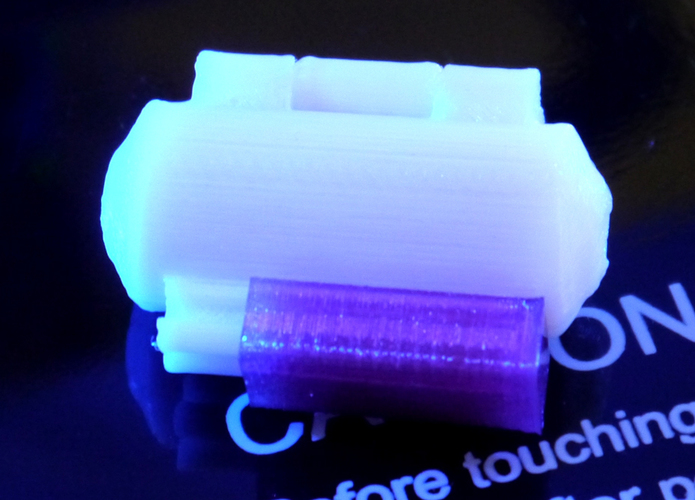

SummaryDownload the dongle version if you want add a retaining cord and/or bell. Update: Decided to add a pair of stringholes for retaining purposes (I sometimes would misplace the little slider.) Then I noticed that when the filament ran out on my Robo3D, this attachment fell onto the plate and made a noise, becoming an erstwhile rollout alarm. I attached a little bell and a string for the most analog of warning bells, and tied it to my filament spool roller. Now it rings pleasantly with a foot or so of filament, plenty of time to prepare a swap. Cool huh? Having used this for a few weeks now, I don't know how I ever did without it. Easy and quick to print, almost no maintenance, and clogs are a thing of the past. Filament cleaning is an easy and necessary step that nearly eliminates clogs as it filters dust and particles before they go into your extruder. This is a universal 2 piece filament oiler with convenient access. It can be fitted on without removing the filament from your extruder. This also means you can oil a spare and rotate it in mid-print. The convenient slide lock is friction/gravity fit and makes swapping a snap. I use a bit of hot glue to secure a small piece of foam to each side and add a few drops of canola oil. Seems to work fine with 1.75 and 3mm filament. As an added safety measure, the clip won't slide on if the filament isn't seated properly in the hole. The foam I used here is from a clown nose I had lying around.Print SettingsPrinter Brand: Robo 3DPrinter: R1 ABS + PLA ModelRafts: NoSupports: NoResolution: .2Infill: 100Notes: I have done quite a few things with printed hinges but this type is the most robust I've found at this scale - kudos to mathgrrl for those. The basic design was inspired by Mark Benson's Split filament oiler/filter/cleaner.

Comments