Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

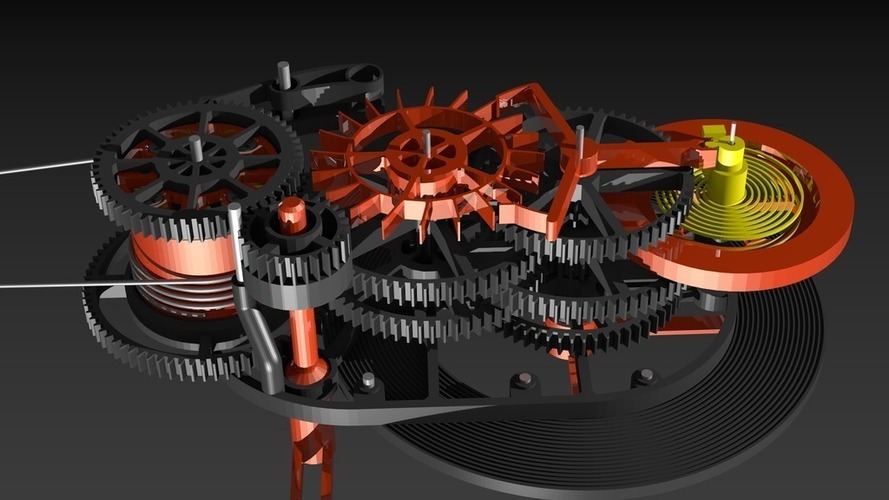

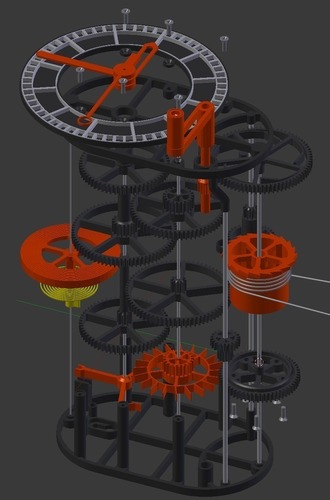

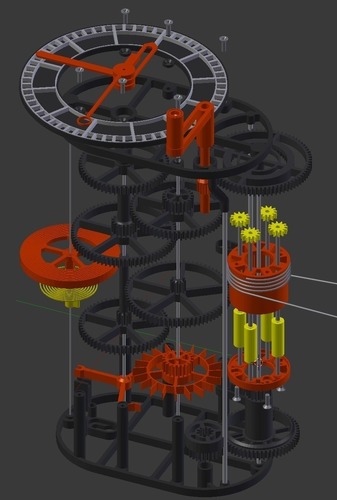

This mechanical clock demonstrates that 3d-printing is not just for decoration. It's possible to create intelligent, living things. The clock has an anchor escapement, and a balance-wheel with a spiral spring. The clock shows Seconds, Minutes, and Hours. The winding has a nested planetary gear, which allows that the clock continues to run, while winding up.

Everything is 3d-printed (even the spiral spring), except e few small screws, some metal pins, the cord, and the lead for the weight. This video shows the clock and the building process (actually with a simpler ratchet-winding):

Video demonstrating the clock (incl. assembly): http://youtu.be/HgZBPYJ2Y-w

Designed with Blender. PLA printed with Rapman 3.2.

Some parts require a loose clearance (hollow shaft for hours and minutes), other parts require a press fit (hands). The 3d-files are optimised for older printers with more inaccuracy in xy, or a badly guided z axis. I.e. when printed with a newer generation printer, parts are most likely too loose. In order to compensate this, the material flow could be increased (overextrusion). In Simplify3d there is another useful parameter: "process settings / advanced / other / horizontal size compensation".

Pins:

- 1 x Balance wheel: 1.5mm diameter, 40mm length

- 1 x Escape wheel: 2.0mm diameter, 28mm length

- 1 x Reduction gears: 2.0mm diameter, 60mm length

- 1 x Drum Transmission: 3.0mm diameter, 60mm length

- 1 x Drum Axis: 3.0mm diameter, 60mm length

- 1 x Crank transmission: 3.0mm diameter, 30mm length

- 4 x Planets Axis: 3.0mm diameter, 39mm length

- 1 x Weight Axis: 3.0mm diameter, 15mm length

Screws:

- 6 x Frame: M3, 12mm, Flat Head

- 5 x Winding Drum: M3, 10mm, Flat Head

There are STL-versions with 2 x 2 combinations for the winding:

a) Simple Ratchet v1: 4.22 revolutions per hour (weight moves 26.5cm/h)

b) Simple Ratchet v2: 2.25 revolutions per hour (weight moves 14.1cm/h)

c) Planetary Drum v1: 3.01 revolutions per hour (weight moves 18.9cm/h)

d) Planetary Drum v2: 1.61 revolutions per hour (weight moves 10.1cm/h)

My clock works well with version c) and 1.2kg weight. For version d) I'd probably need a weight of 2.3kg. The actual needed weight depends a lot on the friction of the whole system.

Comments