Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

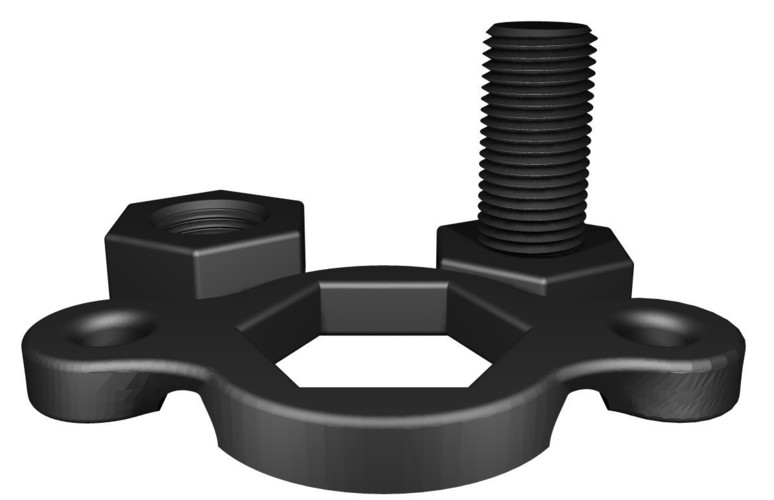

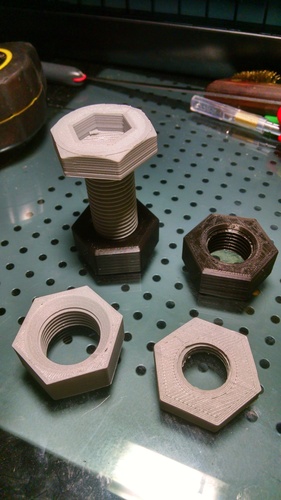

This is a working bolt and nut that I designed, along with a simple hand wrench to fit both. My print of the wrench did not turn out very well, since I used ABS and it wanted to warp very badly. I designed 3 different nuts, to compare tolerances with the bolt... and I've included the one that fits best. I've also uploaded the individual files, so you can choose to print whatever part(s) you want, in any color or material you want.

The bolt is 2.5" tall, and has a 1.7321" head that is 0.5" tall. The threads are 1" diameter and 2" long with a thread pitch of 0.1" (I did not design this bolt to fit anything... I simply started drawing, and these are the dimensions that happened. ) The head of the bolt has a 0.9521" hex opening for an Allen wrench... just for fun. (No, I did not include an Allen wrench... and good luck finding one that will fit.) :) For extra strength, I added a cylindrical hollow area within the length of the threads... which forces the printer to lay down extra shells instead of just infill.

The nut has a 0.9521" inside diameter, and is 0.75" tall. I printed it using black PLA, since I ran out of silver ABS... but I like the contrasting colors, so hush! :) The nut fits snugly on the bolt... in fact, I didn't think it fit, at first. Freshly printed, you may have to trim off just a little bit of the bottom layer in order to get the threads to bite onto the bolt... and apply a little bit of pressure, the first couple of times. After a bit, mine seated right in and work great.

The wrench? Well, I thought it was a nice touch... just for fun, really. As I mentioned above, my print of the wrench didn't turn out. However, my DaVinci 1.0 Pro only goes to 90° C, whereas the Lulzbot TAZ-5 I use at work can go to about 666° C. (Just teasing... but it gets quite hot.) Print the wrench at your own risk.

I printed the ABS parts using SmartBuy 1.75mm silver ABS at 240°/90° C with a 0.4mm nozzle... 0.1mm layers, 3mm shells, 25% honeycomb infill, and 10mm/second print speeds on the surfaces. I used a 10mm brim (which did nothing, really) and low supports... mostly because of the wrench. Even the cheap XYZ slicing software didn't add any supports to the bolt or nut threads, and they printed just fine. Total time for printing all 3 objects with these settings was 19h:14m:15s... using 41.839 meters of filament. Have fun!

Comments