Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

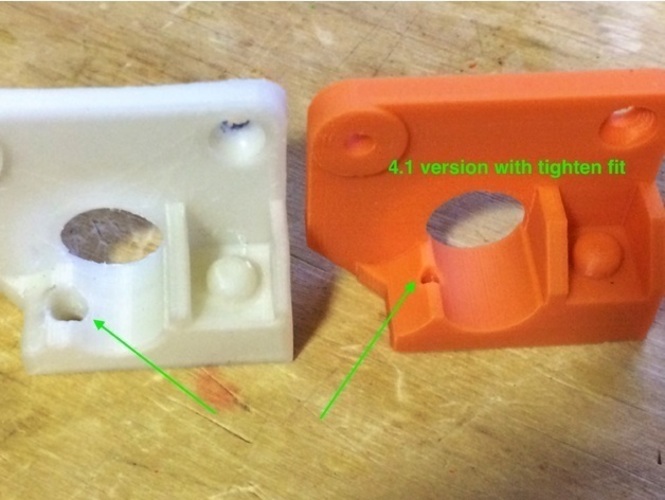

note- Updated ExtruderV4_1 uploaded Feb 9 2017- there are some minor changes that can improve the performance, but also note the tolerances in the filament path are MUCH tighter so make sure your printer is building very accurately

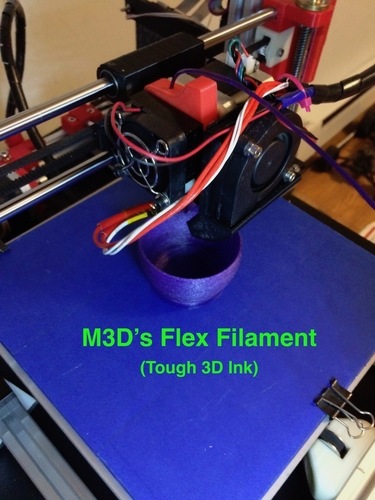

Seen a bunch of extruder mods for flex Filament, some probably better. But I wanted to design my own and make it a exact swap out for my stock one. Honestly it's almost the same basic design with just a few tweaks to get flex filament to feed better and not have a place to curl up or work out of the extruder. Also didn't want to have to get more screws and such.

• direct replacement for Max Micron (and most other Prusa i3 clones) • No extra screws or springs needed, use the ones off the stock setup. • better. more reliable feed into the extruder gear with a longer better directed tube in arm • No place for flex filament to worm it's way out of the extruder like it does at times with stock unit.

notes - I highly recommend using concentric supports if you print with either part flat on their side. about 18% support coverage. Use at least 3 nozzle widths for shell and at least 1mm top/bottom layering. 15%- 20% infill works fine as long as the outer shell is thick enough Add the alternating shell with infill if you have it in your slicer.

if using ExtruderV4_1 please be aware that you can't pull hot filament out as the filament path is very tight with that piece. you need to back out the filament 3-5mm to release from the nozzle and then let cool before pulling though or hot plastic may stick to the extruders throat and block the next filament from being able to load!!

Comments