Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

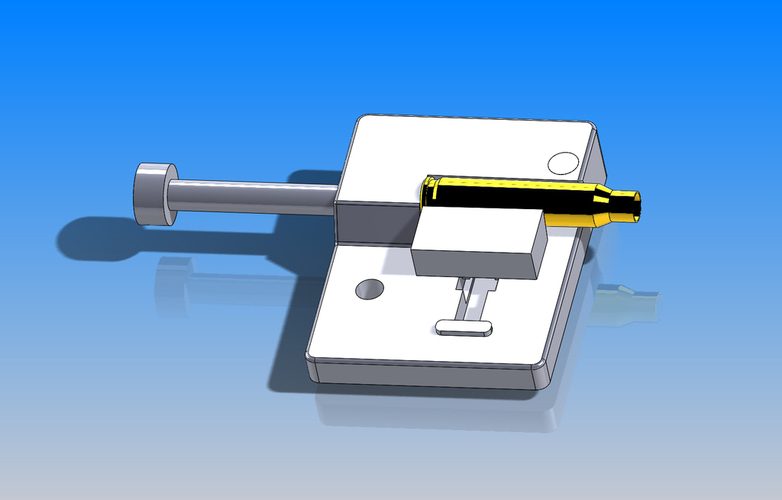

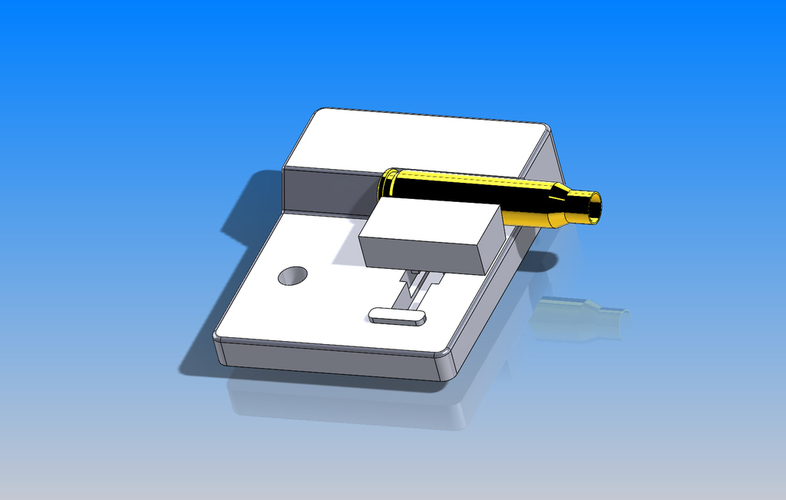

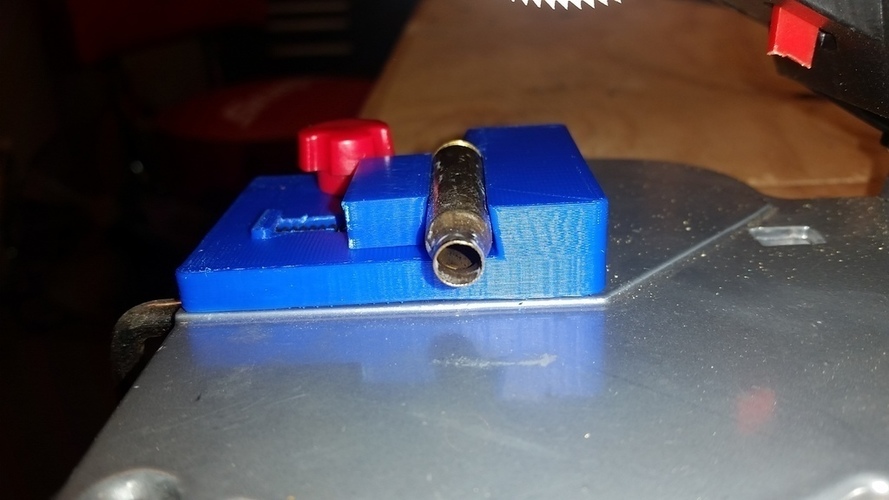

Summary*New V2 needs no support, has a plunger to push the brass off the fixture after it is cut and it shortened the cut length to 1.37"-1.38" for less trimming. It's a jig designed to cut 223/5.56 brass so it can be formed into 300 blackout. It cuts the brass to 1.39"-1.40" on a 2" mini chop saw.Print SettingsRafts: Doesn't MatterSupports: YesResolution: .2mmInfill: 20%Notes: Created V2 which needs no support. The locating pin prints separate and there is also a plunger to be used to eject the brass from the fixture after it is cut. The clamp file is the same for both versions. The fixture needs supports because of the locating pin sticking out on the bottom face. Support it everywhere; there are slots for the clamp to align inside and they need to be flat. Requires an AR-15 Buffer Retainer Spring to work. (.19" dia x .92" long) Remove the factory vise from the chop saw and place the fixture's locating boss into the hole in the saw's base. Place the thumbscrew through the fixture and thread it with the nut in the saw base's bottom groove. Align it square with your eyecromiters. Place the clamp in the slot clearance pocket and slide it forward within the rails. When installing the clamp in the fixture, orient the dovetail so it will be touching the brass. Place the spring in the pocket and you are ready to trim brass.

Comments