Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

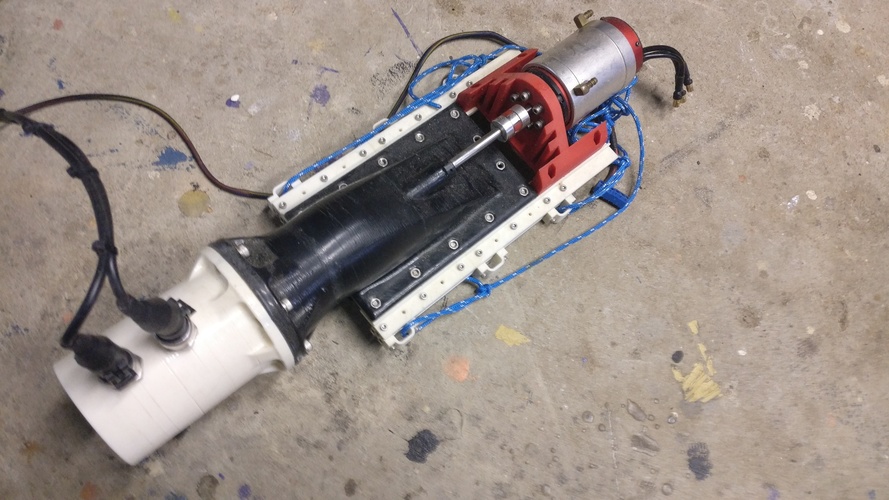

This Water Jet Drive has been developed for a large sized boat, kayak, surfboard etc. This jet drive can produce a flow rate roughly 1000 L/m providing you can give it enough juice

This another several iterations later from my original design (2013), ive worked on this on and off for a long time and its finally needs to be put to rest.

Design All design work is done in AutoCAD but recently i have redrawn it in Fusion360 to take advantage of simscale integration to play with their CFD. The design is made with 3 parts inlet, middle zone and the outlet.

Inlet

Middle Zone This is where all the magic happens, the water is compressed slightly (form 70mm to 60mm), the turbulance is taken out (tried) and has a few key features like 2 water suction inlets for removing water from inside the vessel (also has inbuilt check valves for safety) and a water inlet to cool the motors water jacket.

Outlet I have several output "nozzles" that will fit this flange i've designed. Check my other designs out

Flanges This has been a steep learning curve as i have on several occasion had the flange on different designs fail spectacularly. But with all the testing i have done on this rig, not even a drop comes out. the flanges have been located so they are not in any high stress zone (especially over the propeller), since there has been consideration for some silicon inside the female part of the flange i recommend putting a small beed (~1mm) the entire way around, and let dry before assembly.

Power Plant This pump is not for the faint hearted, going from a 500W 560 motor to a 2200W outrunner and now a Leopard 5698 875kV. This can do 5500W, ive had this drawing 230A with an 8S2P lipo pack. So that's a tad under 7000W (at 3.8V), so it has some punch out of the hole. It was interesting trying to hold this and giving it a boot.

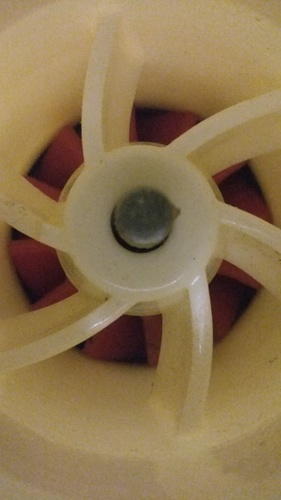

Propeller Printed with ABS . I have never had a 3d printed prop fail even putting massive power (relatively) through it. Im still using my original printed prop, as i want to produce some pump curve RPM VS Flow rate VS Power Input for several different prop designs to "tailor" a solution to anyone needs. i have several designs but the following are availiable

- 8 Blade, 70mm OD (original)

- 6 Blade

- 12 Blade

Shaft 8mm Rigid stainless steel shaft

Shaft Support 3* 8mm ID x 16mm OD sealed chrome bearings

Motor Mount 3d printed mount it has adjustment vertically,

Shaft Coupling I used a aluminum spider coupling bought off ebay, motor shaft is 8mm and prop shaft is 8mm so a flexible coupling is the best suit as nothing is perfectly manufactured and it does a good job of removing some vibrations

Flow Rate 1000L/min calculated by crunching some numbers. I have struggled to actually measure this bad boy as nothing is in this range (cheaply) unless i go to an industrial device ($$$$). I ended up making a venturi (printed of course) see my other designs.

Simulations after redrawing this in AutoCAD's fusion i used SimScale to run the CFD on different props. See the simulation results since its a public project (Link TBA)

Check out my other designs http://www.thingiverse.com/benny90/designs

Need something designed or printed swing me a message onhttps://www.makexyz.com/printer/benny90 or contact me though Thingiverse

Comments