-

-

Search our Marketplace

-

- Software

- Manufacturing

- Industries

-

Materials

Not sure what material to choose? View 3D Materials Guide

- ABOUT Marketplace

- Get a Quote

- Sign In

-

0You haven't added any 3D printed products yet.

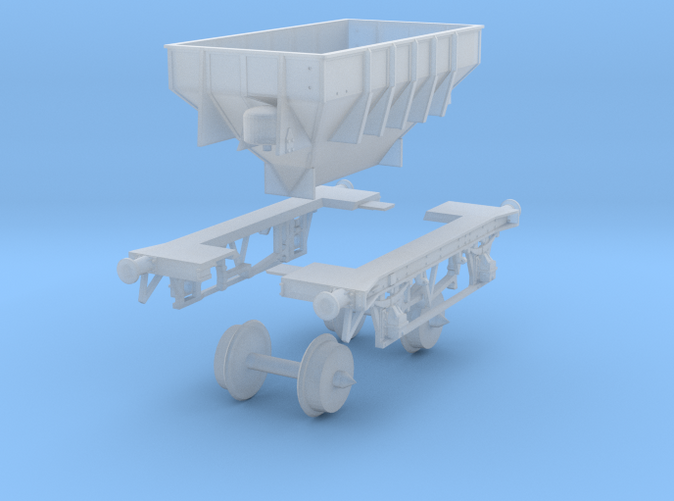

This is a GWR design P22 ballast hopper, built just after nationalisation by British Railways. They were also known as Herring, and were TOPS coded ZLV. I have no idea how well the FUD acrylic wheels will work, but they could be substituted with Parkside Dundas 3-hole disc wheels if you don't trust the pinpoints to wear well (this is why the chassis has been made in two parts rather than printing the wheels in situ). The bearing surfaces inside the axleboxes might also benefit from fitting bronze axle bearing cups from the 2mm scale association. A bit of an experiment. There is scope for adding more detail (brake handles are the most obvious, then the hopper opening bars, handholds on the hopper corners, and more brake rodding, maybe drawbar hooks and links) in fine wire or spare bits from plastic and etch kits. I think this is better than having too many exposed and flimsy bits to break off along the way. I'm pretty sure there will be enough room to fit couplings. Some careful fettling with scalpels and files is likely to be needed to get everything to fit together nicely before gluing, and I plan to paint the hopper and chassis while they are still separate. Will sell if it all works. UPDATE After feedback from Shapeways I have now made the hopper walls thicker so it is more likely to hang together during manufacture, not to mention subsequent assembly by me. I also took the opportunity to rotate the model 180 degrees around the z-axis in Blender so you can see the vacuum cylinder and the hangers for the brake camshaft in the stationary depiction. This brake shaft is not included in the printed model as it would be rather prone to breakage. It could be added in wire, but the space it needs may be required for the coupling anyway. UPDATE The one-off print of the first version was just amazing! The parts fitted together really well with only a little filing of the "tongues" to give a sliding fit between the chassis halves, and the wheels turn freely. Well done Shapeways! A few improvements have been made in this version. If you fancy a go, let me know and I'll e-mail you my construction notes and photos. In return, I'd love to hear how you get on. UPDATE: The changes were successful, the chassis halves now fit together well after cleaning, without any filing at all, and there is no slap so I haven't overdone it.