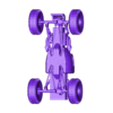

Loved the hot rod Ossum made so much I had to make one. I wanted it to be functional as an actual rock crawler so I put most of the weight up front and down low for steep climbs.

I designed it to work with an axial ax10 wraith or scx10 style transmission with an extended output shaft I had laying around. I am using my old rr10 bomber drivelines and ar60 axles on 2.2 wheels and tires.

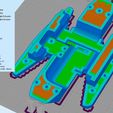

This is designed to be printed on my anet a8 with a 220x220 mm bed, 200x200 is probably no problem as well.

The overall wheel base is 380mm so its a monster.

Rear links are 120mm

Front Links 160mm

Still need to finish the front battery tray for looks and shock mount is weak.but these files are drive able as you can see in the pictures.

Update V2:

Added assembled non print version.

Updated battery tray (Unprinted) Radiator in front doesn't look great from my slicer, need comments on how to improve. maybe just reduce detail. I print at .3.. on this.

Added Battery Lid (Unprinted) Not as easy to print as I would like and no mount system. so if your need this printed now, you can just drill holes down through the edges and install screws, or maybe double stick tape.

Update V3:

Ok so I didn't realize before I make an stl I should combine the parts into a single solid, then convert to stl. So some parts may print funky. Just fixed Battery tray, need to review other parts.

Deleted old files, Should I do that?

Going to need to beef up upper link mounts.

Update 3.5

no upload at this time, but v4 will only use the same bed, roof and grill.

old Cab, battery tray, battery lid and skid will not fit properly. so hold off printing those for now.

Update v4

New skid with reinforced upper link mounts

battery lid should clip in

new battery tray

new cab

updated whole 3d view

Update v4.1

Slight modification to gear thicken gear cover on battery tray.

I'm not putting this as finalized yet, but its pretty damn close, I might add headlights to the battery tray, and it needs some testing, but I am printing it, and probably will not print any following versions myself, unless I find a major hidden flaw.

Status after v4.1 I have reprinted most of the parts, not including the cab, I am using the original ossum cab printed at 80% height (found here https://www.myminifactory.com/object/3d-print-35986 with some body clips I printed and keep cutting down I will probably add later as an alternative method of assembly) . I have noticed the cab I designed "may" have issues fitting together during assembly. I didn't leave a whole lot of wiggle room preferring just to grind down the plastic with a rotary tool if necessary. if you have any issues or broken parts please let me know in the comments and I will attempt to fix them. Also after adding the spur gear shroud I realize the maxim spur that will fit under it is a 56t stock axial gear. If you want a larger 68t gear for low speed you will need to cut that wire safety shroud off.

Drove this in the rocks for a few hours.

Had no breaks.

Everyone loved it

The issue with assembly has to do with the screw holding in the front upper links. I used long screws that don't allow the battery tray and cab assembly to drop straight down to the chassis. The cab I modified may flex enough to fit depending on the hardware used. But I still haven't printed the current body to test.

7/27 added some other grill options. Added a battery tray with exhaust that is 3mm wider so it wont rub the doors as much during assembly, it also has a larger spur gear cover to fit larger spur gears (not sure how large, it can still go larger though).

I'm calling this finished. Anything else I do will be optional upgrades. But will still fit previous versions.

Here is the fusion 360 file of the complete build, if you use it please share you files with the rest of us.

https://a360.co/2vtigru

Here is a horrible youtube video of the thing in action https://youtu.be/UCwjHNRoGoQ

8/8/18: Added body clamps for origional body

8/11/18: Added Rollcage and Rollcage with spare tire mount thanks for the idea carlton267

8/25/18: I printed this current version finally, I see there are still changes I need to make concerning the mate between the Cab and Battery tray. Its possible to cram them together, or grind material away to assemble them easier, but it can also be fixed, so I should do that.

9/18/18: v5 OK, so I redesigned the way the cab mounts to the battery tray. So now the cab should be able to slide straight down over the tray and there is no forcing alignment. also the mount screws are more accessible, especially with long hex Drivers. Optionally I beefed up the back corners of the truck bed so the top tips aren't so easy to break. No changes to other parts.

9/25/18 Rotated Cab STL

12/3/2018 I recommend drilling 3mm holes between the bed and the cab and putting bolts between them, as there is a weak spot in the skid I have broken twice. mounting the bed to the cab would fix the issue. The weak spot is where the lower link screws go under the motor.

01/29/2019 (beta v6) Added the holes from the cab to the bed as recommended in previous comment. Overall I am very happy with the performance and durability of this car. As 3d printed parts fail I redesign them for extra durability in these areas. Right now the only issue I have is with the long screws that hold the lower links and the cab to the battery box. They grab the plastic so hard sometimes the screws fail during first assembly. I have not thought of a remedy or procedure to alive the issue other then drilling out the holes some. I am not wanting to bore out the holes in the stl in fear they might get too loose.

02/03/2019 updated the fusion 360 shared file to current version, its a hacked together file with excessive junk all over it, but that's my workflow. https://a360.co/2vtigru

/https://fbi.cults3d.com/uploaders/20002883/illustration-file/34efe7c5-e692-4a3a-ad77-091c3b94dc41/20180623_193650.jpg)