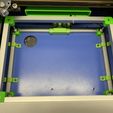

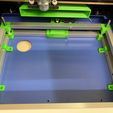

Motorgetriebener Werkstücktisch für den K40 CO2-Laser.

Werkstück kann so immer optimal im Fokus des Lasers platziert werden.

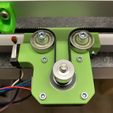

Verfahren wird mittels Zahnriemen und Trapezgewindespindeln (8mm Steigung).

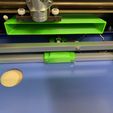

Motorplatzierung unter Ablufthutze (hinten)

Steuerung mit Arduino Nano und einem A4988 Stepper-Treiber und Pancake-Stepper.

Arduino-Sketch (BETA-Version) ist im Download enthalten: K40_MotoLift_Table.ino

Gesteuert wird über vier Tasten:

1mm aufwärts, bei längerem Druck Dauerfahrt

0,1mm aufwärts Feineinstellung

1mm abwärts, bei längerem Druck Dauerfahrt bis zum Endschalter unten

0,1mm abwärts Feineinstellung

BOM als Excel-Liste enthalten.

Schaltplan als .pdf enthalten: Circuit_Diagram_K40_MotoTable_Control.pdf.

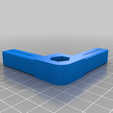

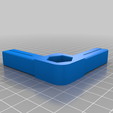

Rahmen wird aus 15x15mm Vierkantrohr (1mm Wandstärke) konstruiert.

Gekürzte Ablufthutze für maximalen Arbeitsbereich (passt nicht auf alle K40-Bauformen)

Zum Verbinden des Zahnriemens funktioniert dieses Teil hier sehr gut:

https://www.thingiverse.com/thing:4175874

12012020 Update:

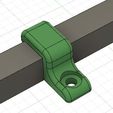

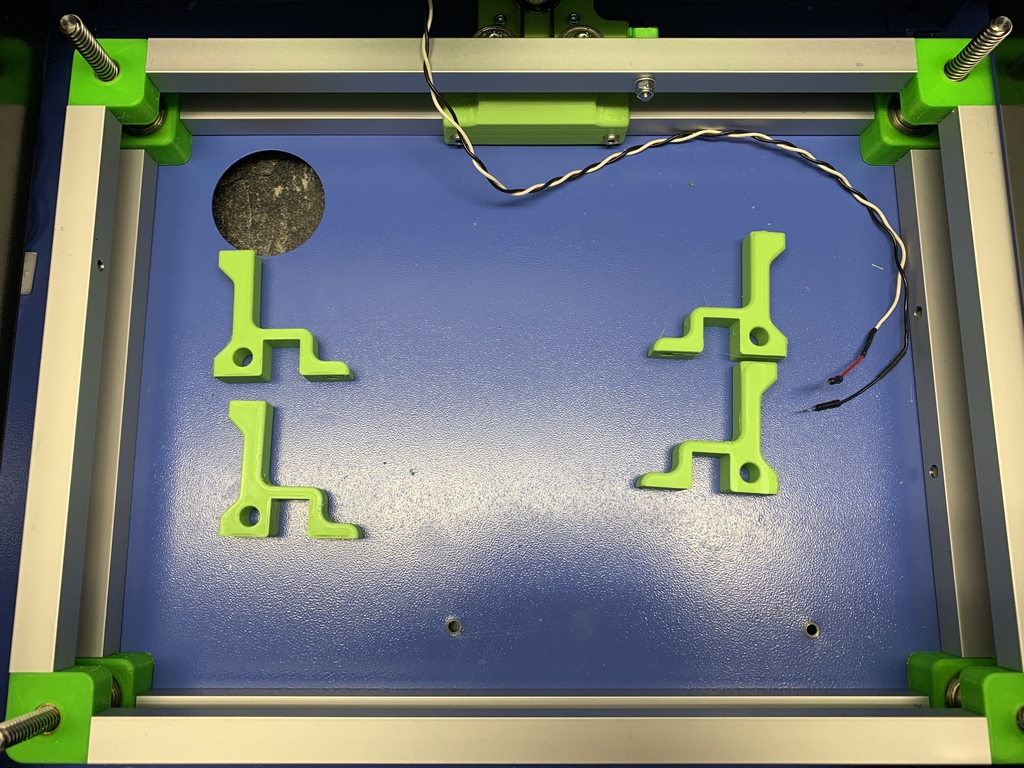

Befestigungsklammern mit Abstandshaltern zu Laser-Führungsschienen integriert, da Bodenplatte beim K40 oft gewölbt. So ist eine parallele Montage des Tisches zum Laser-Verfahrweg möglich.

04022020 Update:

Oberteil für M8 und M10 Muttern bei Verwendung von Gewindestangen statt Trapetzgewindespindeln ergänzt.

27.10.2020 Update:

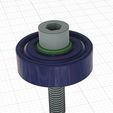

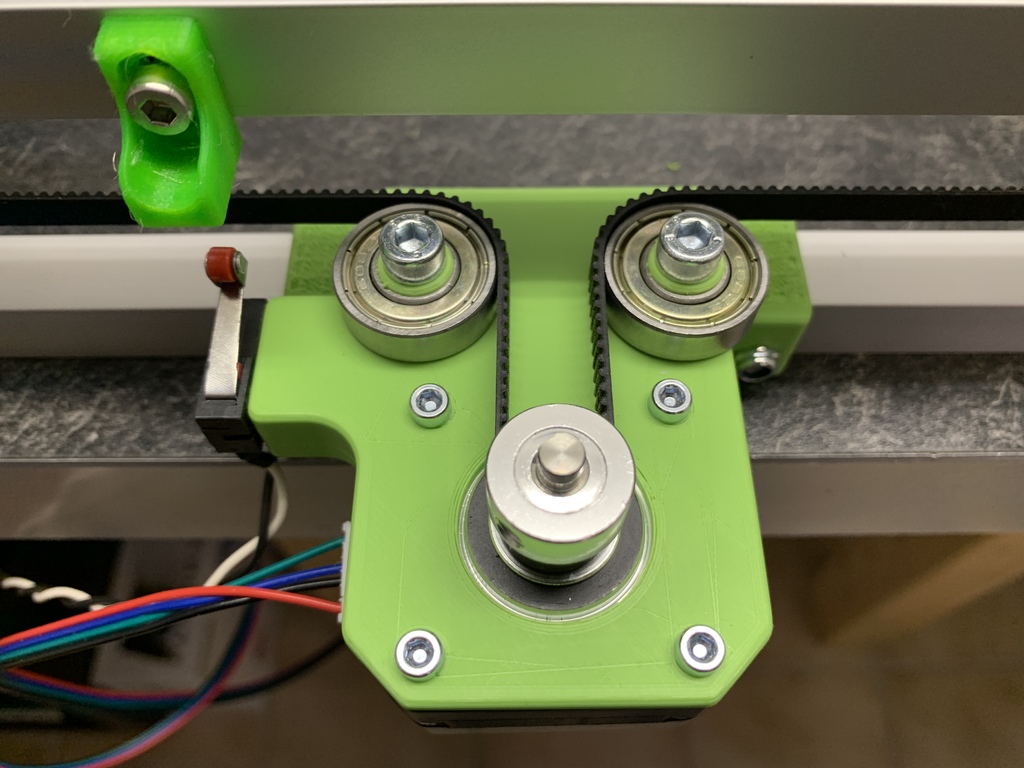

Riemenspanner zur Verwendung mit geschlossenem Riemen ergänzt.

Benötigt werden 3 x 608 Kugellager, 2 x M5x25, 1 x M5x20 mit selbstsichernder M5 Mutter, sowie 6 x Bearing_disk_belt_tensioner.stl und 1 x Belt_tensioner_F40_table.stl

Ausserdem die Befestigungsschrauben am Rahmen

01.02.2021 Update:

Integration OLED-Display zur Anzeige der Tischposition, Integration RESET-Taster zum Nullstellen der OLED-Anzeige, Anzeige Tischposition auf 0,1mm genau, Schnelles Verfahren durch dauerhaftes Drücken der 1mm UP/DOWN-Tasten. Position wird auch bei schnellem Verfahren mitgeschrieben und nach loslassen der entsprechenden Taste angezeigt.

K40_MotoLift_Table_V02_OLED.ino

Circuit_Diagramm_K40_MotoTable_Control_V02_OLED.pdf

Motor-driven workpiece table for the K40 CO2 laser.

Workpiece can always be optimally placed in the focus of the laser.

The procedure is carried out using toothed belts and trapezoidal thread spindles (8mm pitch).

Engine placement under exhaust hood (rear)

Control with Arduino Nano and an A4988 stepper driver and pancake stepper.

Arduino sketch (BETA version) is included in the download: K40_MotoLift_Table.ino

It is controlled via four buttons:

1mm upwards, with longer pressure continuous driving

0.1mm up fine adjustment

1mm down, with longer pressure continuous travel to the limit switch below

0.1mm down fine adjustment

BOM included as an Excel list.

Circuit diagram as .pdf included: Circuit_Diagram_K40_MotoTable_Control.pdf.

Frame is constructed from 15x15mm square tube (1mm wall thickness).

Shortened exhaust air scoop for maximum working range (does not fit all K40 designs)

This part works very well to connect the timing belt:

https://www.thingiverse.com/thing:4175874

12012020 update:

Fastening clips with spacers integrated to laser guide rails, since the base plate of the K40 is often curved. This enables the table to be installed parallel to the laser travel path.

04022020 update:

Upper part for M8 and M10 nuts added when using threaded rods instead of trapezoidal threaded spindles.

10/27/2020 Update:

Belt tensioner added for use with closed belt.

You need 3 x 608 ball bearings, 2 x M5x25, 1 x M5x20 with self-locking M5 nut, as well as 6 x Bearing_disk_belt_tensioner.stl and 1 x Belt_tensioner_F40_table.stl

Also the fastening screws on the frame

02/01/2021 Update:

Integration of OLED display to display the table position, integration of RESET button for zeroing the OLED display, table position display with an accuracy of 0.1mm, fast movement by pressing the 1mm UP / DOWN buttons continuously. The position is also recorded when moving quickly and displayed after releasing the corresponding key.

K40_MotoLift_Table_V02_OLED.ino

Circuit_Diagramm_K40_MotoTable_Control_V02_OLED.pdf

https://youtu.be/CZ4sGklHOlw

/https://fbi.cults3d.com/uploaders/22927427/illustration-file/b1a374cb-a9c8-47cf-ad3b-a88664ba32d3/IMG_0868.jpg)