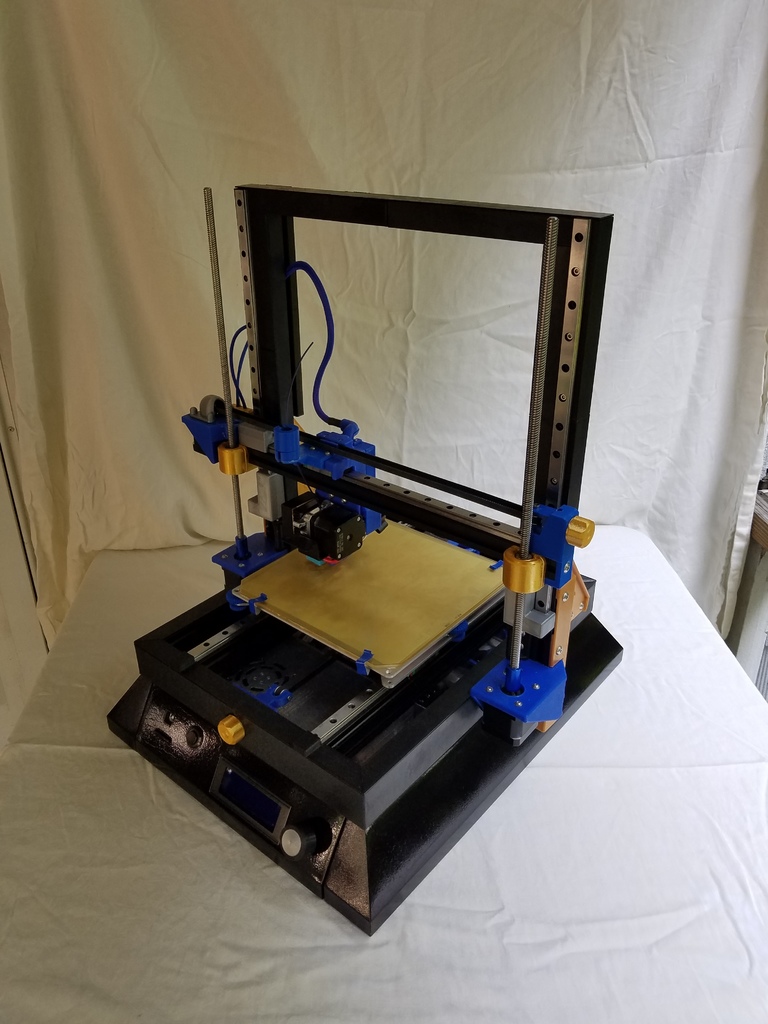

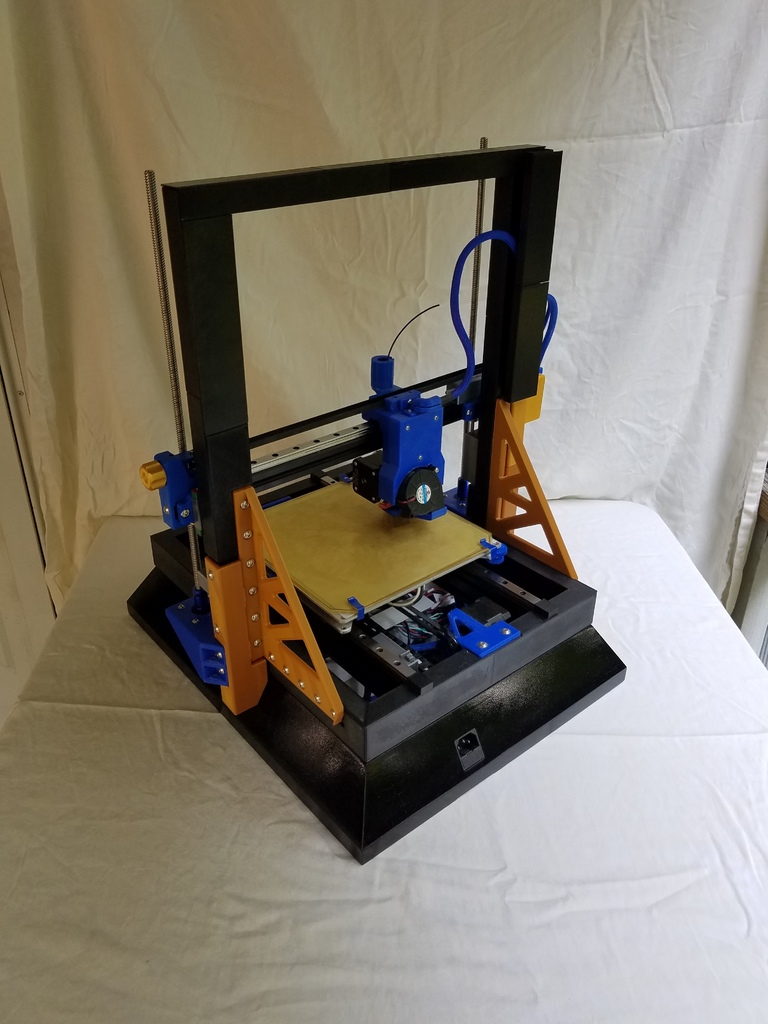

First off: Initial credit to pheneeny for his AM8 design.

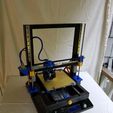

I actually bought an A8 just to upgrade it, back in July of 2018.

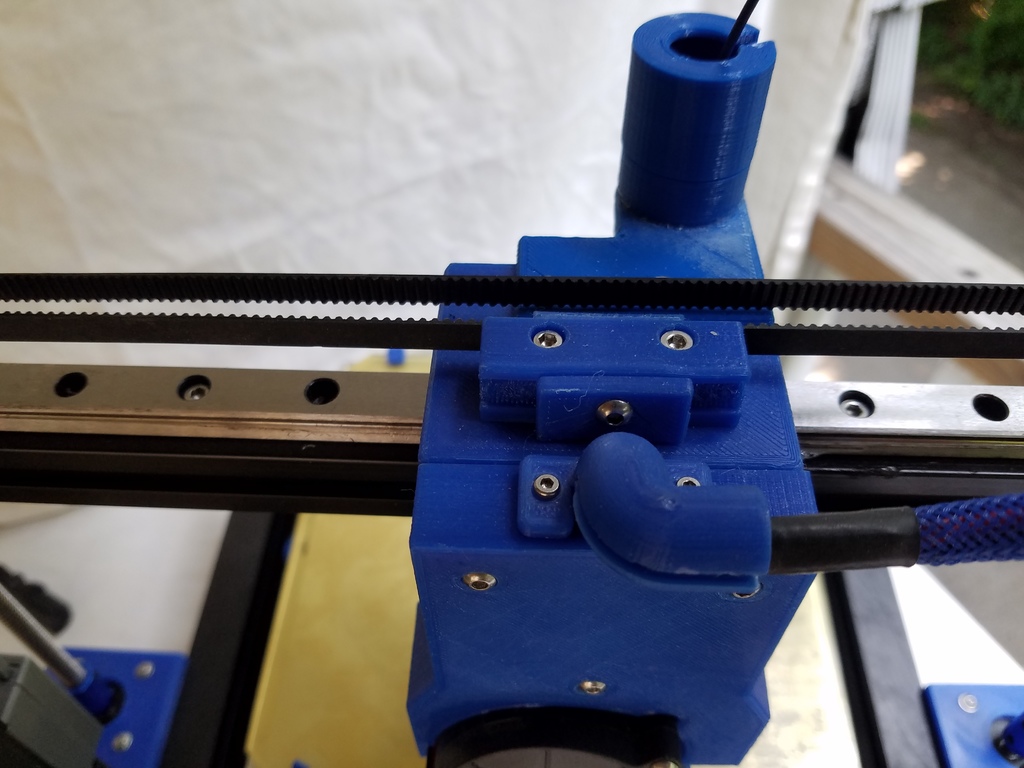

Then, major credit as well to BLV for his MGN12 upgrade.

As he said, “Why not?”

The linear rails make all the diff, IMO.

And thirdly, major appreciation to Paul Cole, who so kindly sent me info about his Mega and dual Z stepper functionality. Thank You!

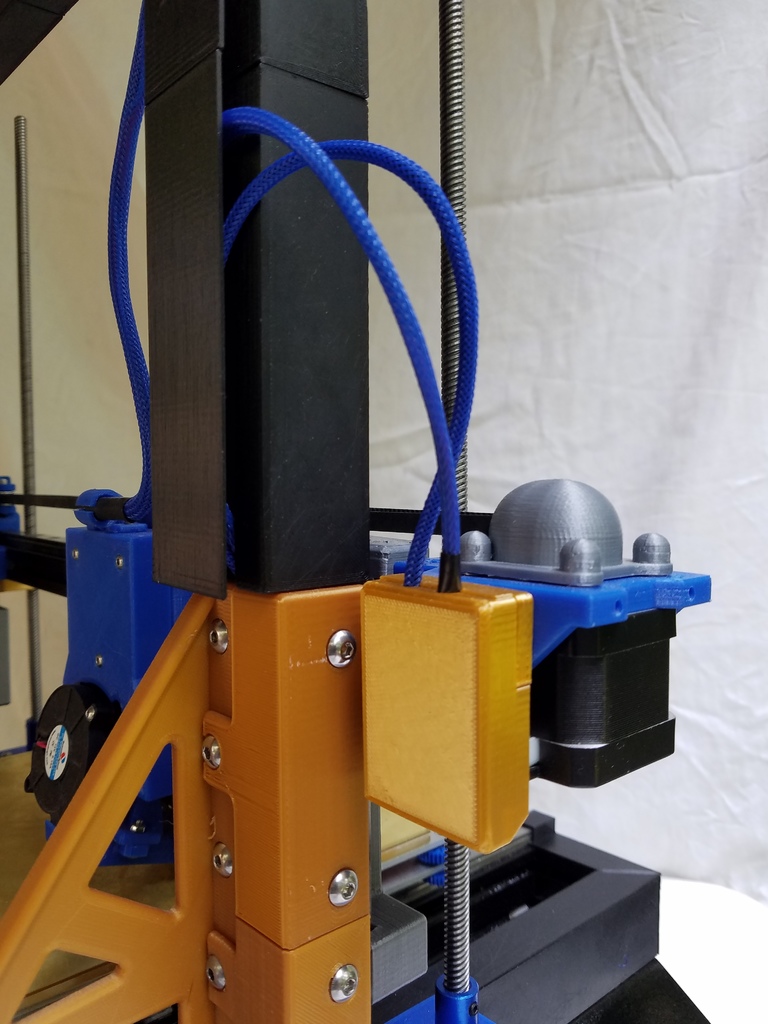

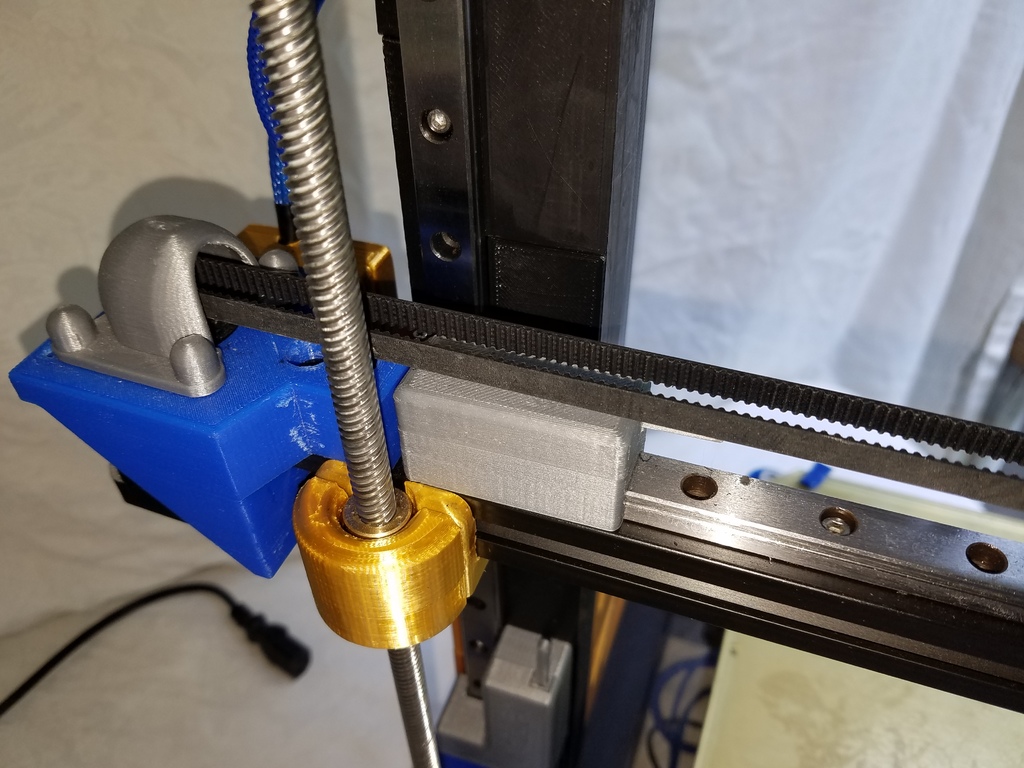

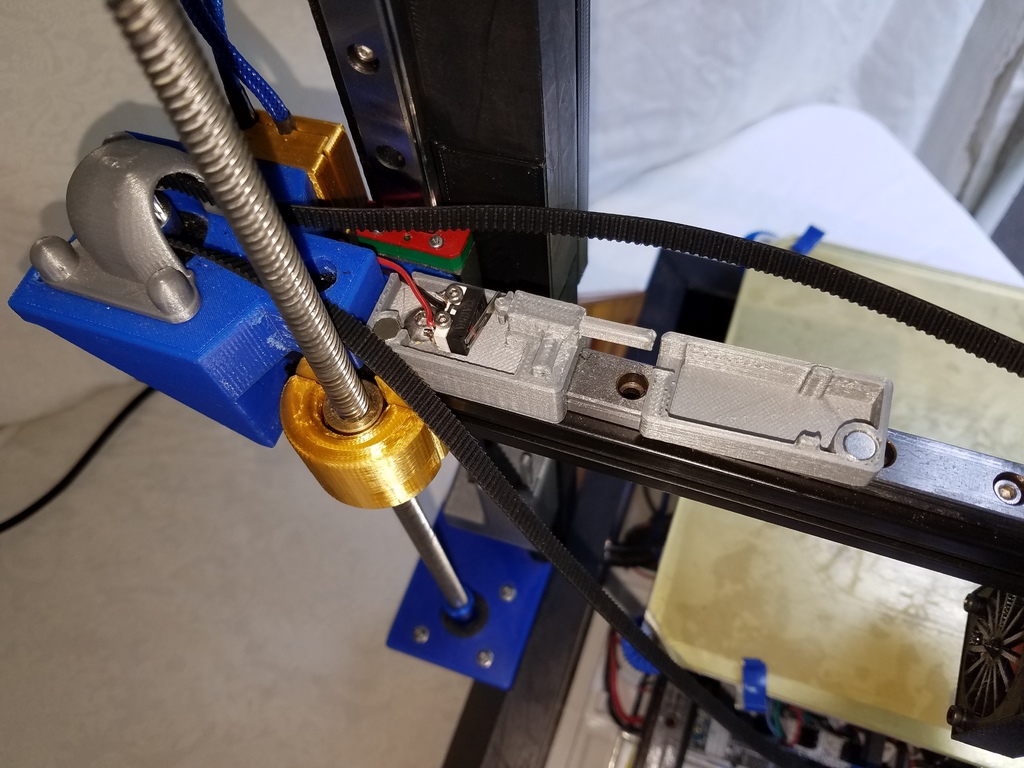

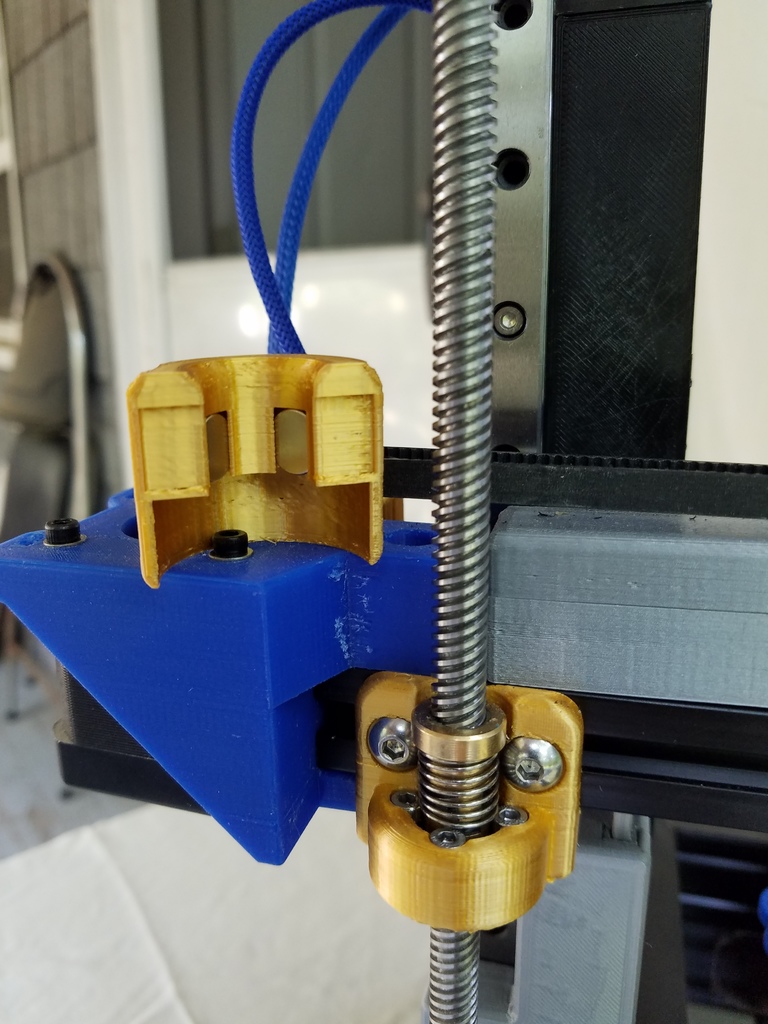

UPDATE: I have added Z-axis pillow blocks to isolate the Z lead screws from their motors.

See Thing https://www.thingiverse.com/thing:3933127 for details.

Well, the only A8 parts in it are the motors, their wire harnesses, and the burnt out hot bed serving as a plate for a stick on heating element.

It’s on RAMPS 1.6, with TMC2208's, running Marlin 1.1.9.

So it’s not an AM8, but it does have the BLV MGN characteristics.

But I believe that’s about all.

I printed most of the parts for this on my Maker Select V2.

Once the Mi3 was functional, I printed the last few cover parts for it on it.

I have not included any STL's or design files, but if anyone is interested in anything, please Message me. It was all done in SolidWorks.

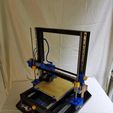

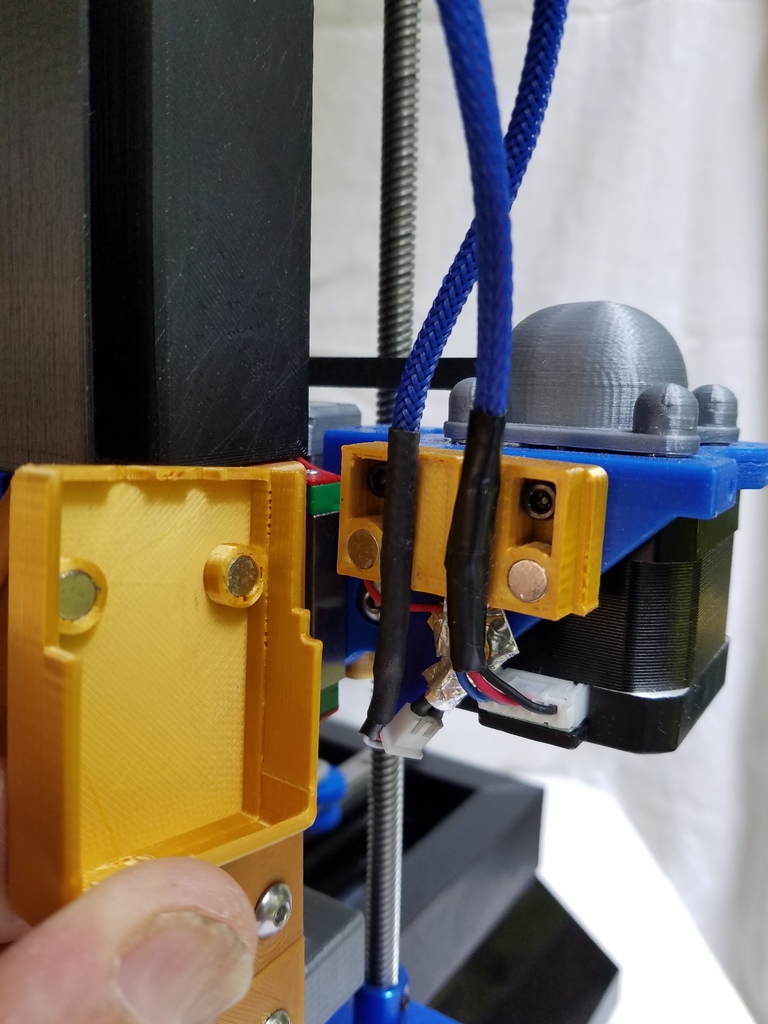

I had a vision when I started this, and that was to keep it as clean as I could, meaning: no visible wires. A wire harness/bundle made to look good, yes, but not wires.

The printer frame is 2040 and 2020 aluminum extrusion from Misumi, but it's mostly all covered by plastic cover plates, simply because I did not like the color of the so-called "black anodized." Looked more like brown to me, hence the covers. They all snap on/off.

The frame is all tapped, drilled and assembled using M5 x 25mm socket head capscrews.

The ONLY bracing it has is the 2 gantry supports: no other corner bracketry or bracing of any type is used or needed. I pick it up by the top cross-rail and carry it. It weighs 39 lbs.

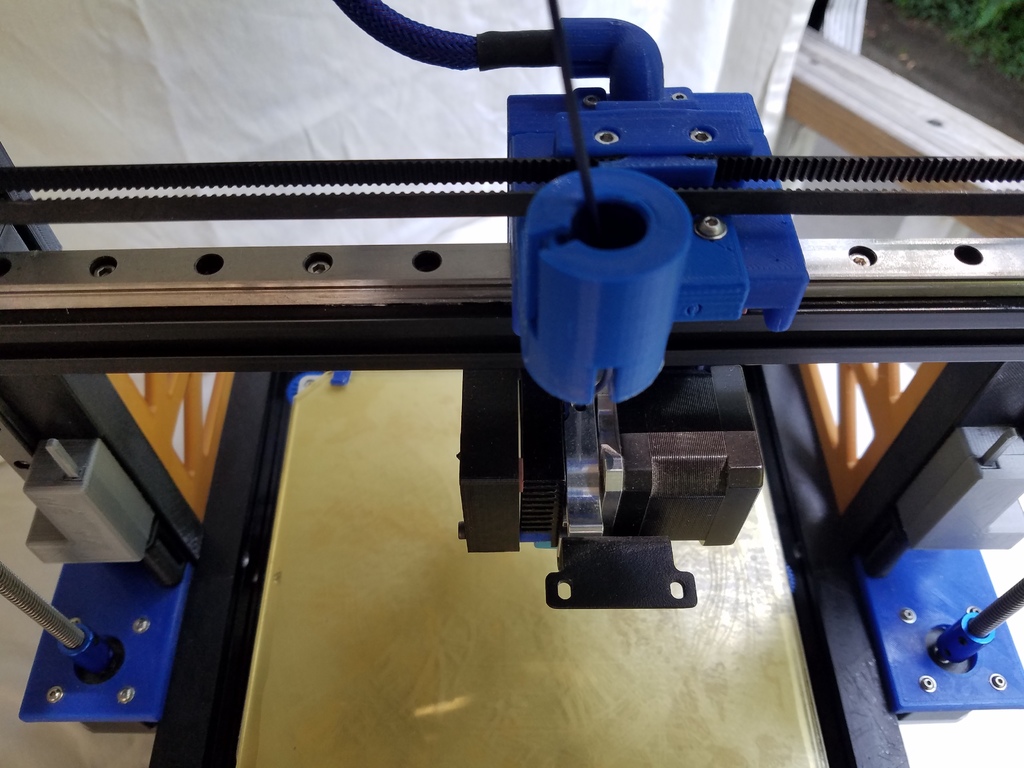

I changed the top cross-rail to a 2020 and ran it across the tops of the gantry verticals. That gave me back a whole lot more vertical space for taller parts.

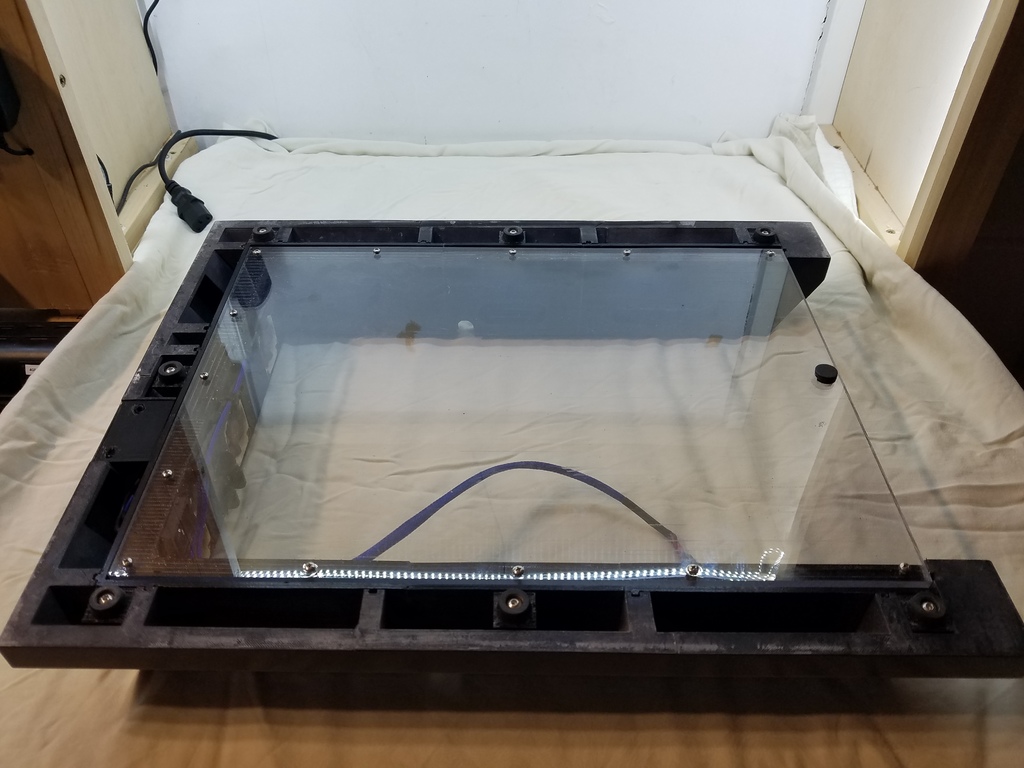

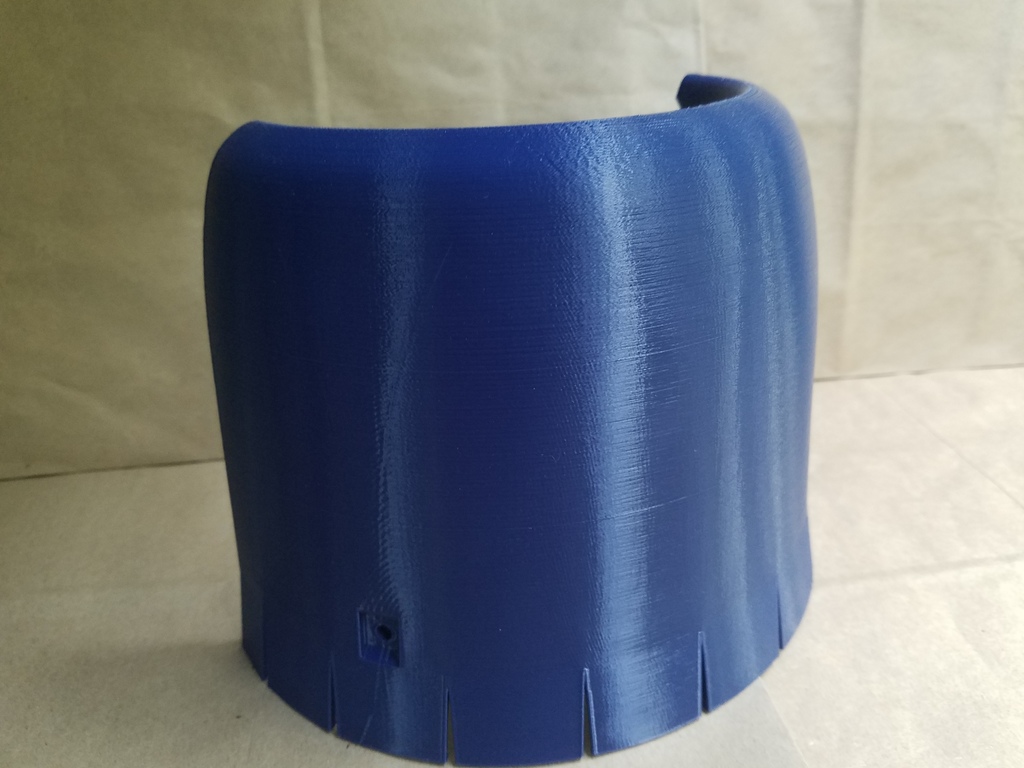

The entire printer sits on a plastic support frame, which is surrounded by a plastic decorative shroud. The support frame has 3 4010 Noctua exhaust fans for getting rid of the heat.

There is a sheet of plexi-glass between the printer and the support frame, so nothing falls into the visible underbelly.

The printer then then screws down to the support frame in the 4 corners under the snap-on covers.

I put all the electronics in a drawer just to get them OFF the printer and out of sight.

All wiring easily unplugs/attaches.

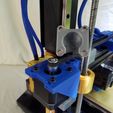

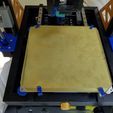

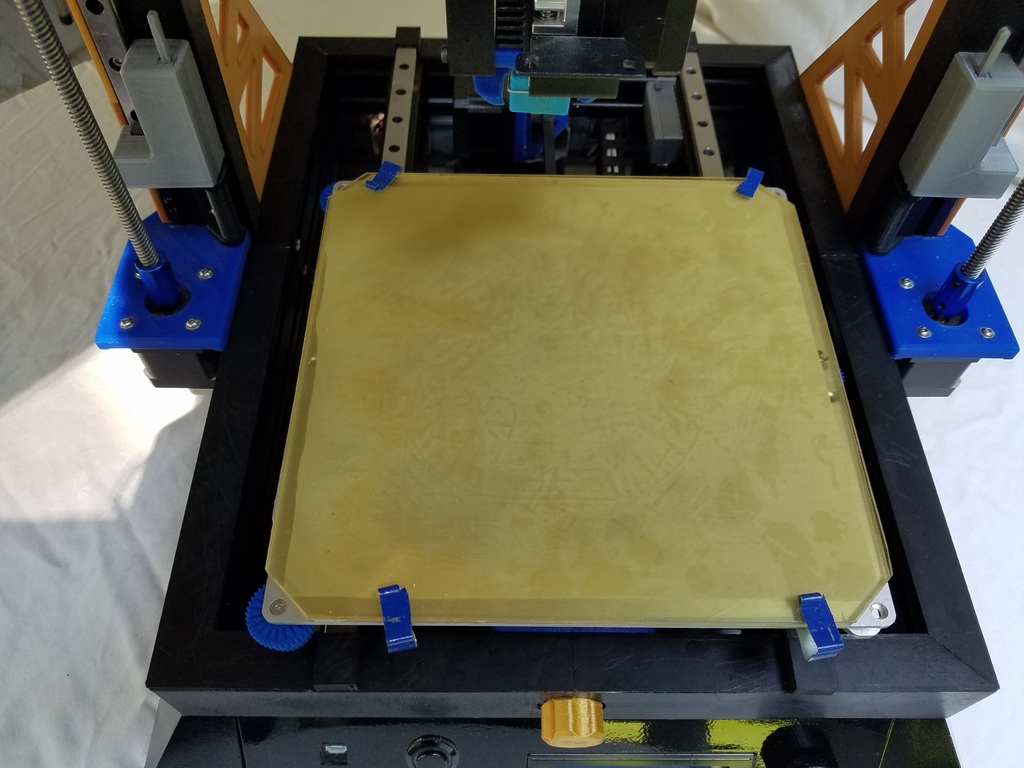

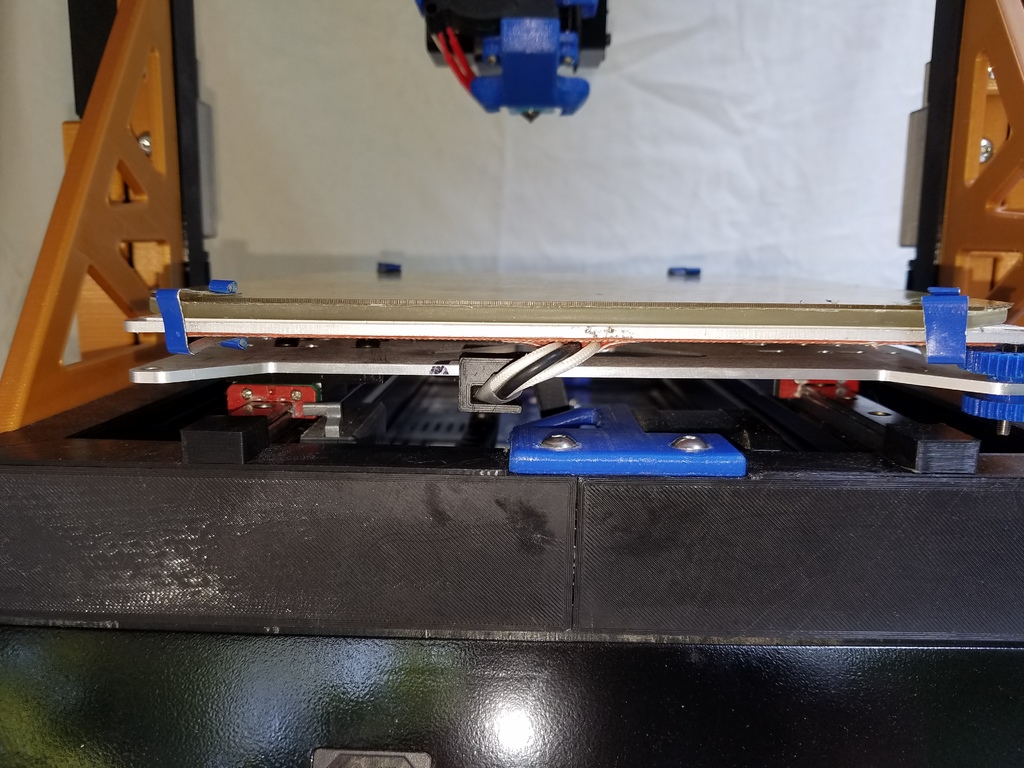

The Y plate initially used 3 carriage blocks: 2 on 1 side and 1 on the other.

I recently added back in the 4th block: eliminates the flex in the Y plate.

The hot bed is mounted on 3 points: 2 corners and the center of the opposite side, and locked with locking thumb-wheels.

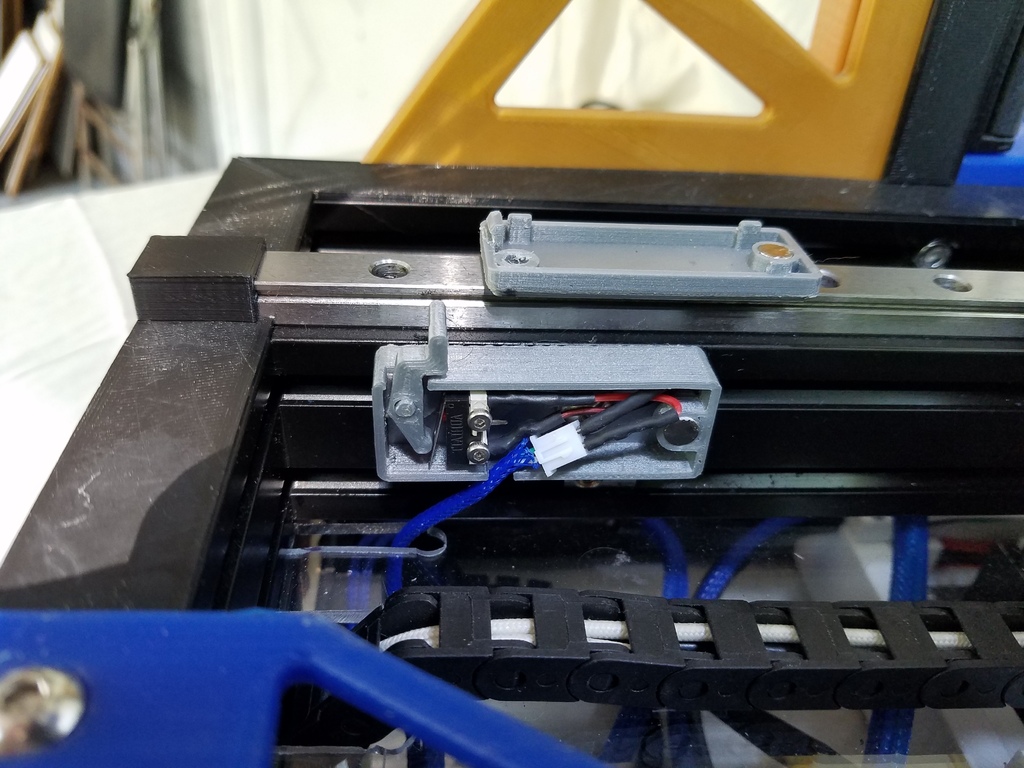

The Z axis is managed/driven by independent Z motors and end stop switches utilizing the dual stepper feature in Marlin to auto level the X at the start of every print automatically.

Those of you who own an AnyCubic i3 Mega (and some others) know just what I'm talking about. Heaven.

The hot bed is a self-adhesive from GulfCoast Robotics, and the cable chain rides on the plexi separator sheet to the rear and down into the drawer.

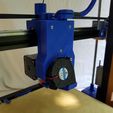

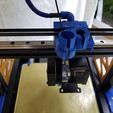

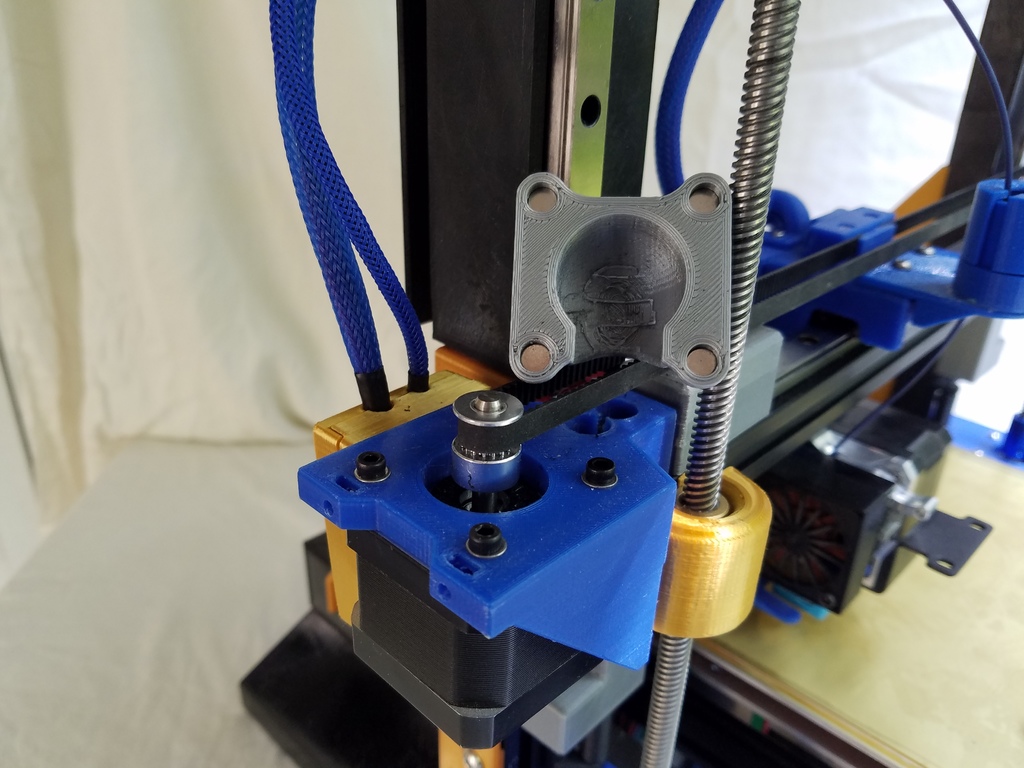

The extruder is an exact clone of the upgraded DD extruder I have on my Maker Select V2.

Micro Swiss everything, all metal, hardened .04 nozzle, screw-in thermistor, even the metal extruder mounting plate. It allowed me to hang the extruder directly underneath the X axis rail.

There is much more to say, but.... I'll let the pics do the rest of the talking. :-)

Thanks for viewing!

And oh yeah, it prints SO nice too.

I've added a couple pics of some RC airplane parts I'm printing from 3DLabPrint.com.

/https://fbi.cults3d.com/uploaders/16680056/illustration-file/06eb84c2-076f-4285-8390-987ad86bbd52/20190727_104243.jpg)