Parts.

I acquired the following parts:

• Two R30 O-Rings (44 ID 3.5 Section).

• One R18 O-Ring (22 ID 3.5 Section).

I 3D printed the following parts at .15mm layer height, 20% infill unless noted otherwise:

• One "Axle, Pallet.stl".

• One "Axle, Wheel, Front.stl

• One "Bolt (8M by 1.25 by 16).stl

• One "Escapement, Compound (1.12m 10t).stl".

• One "Frame, Left.stl".

• One "Frame, Right.stl".

• Two "Gear, Axle (1.12m 10t).stl".

• Two "Gear, Compound (1.12m 50t, 1.12m 10t).stl".

• One "Gear, Pawl (1.12m, 50t).stl".

• One "Knob and Axle.stl", 100% infill.

• One "Pallet.stl".

• One "Pawl.stl".

• One "Spring.stl". 100% infill.

• One "Tiller.stl".

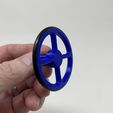

• One "Wheel, Front.stl".

• Two "Wheel, Rear.stl".

This is an extremely high precision 3D print and assembly model using at times very small precision 3D printed parts in very tight spaces. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely certain that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly thus an M8 by 1.25 tap and die will assist with thread cleaning if necessary.

Assemble the Rear Wheels.

To assemble the rear wheels, I performed the following steps:

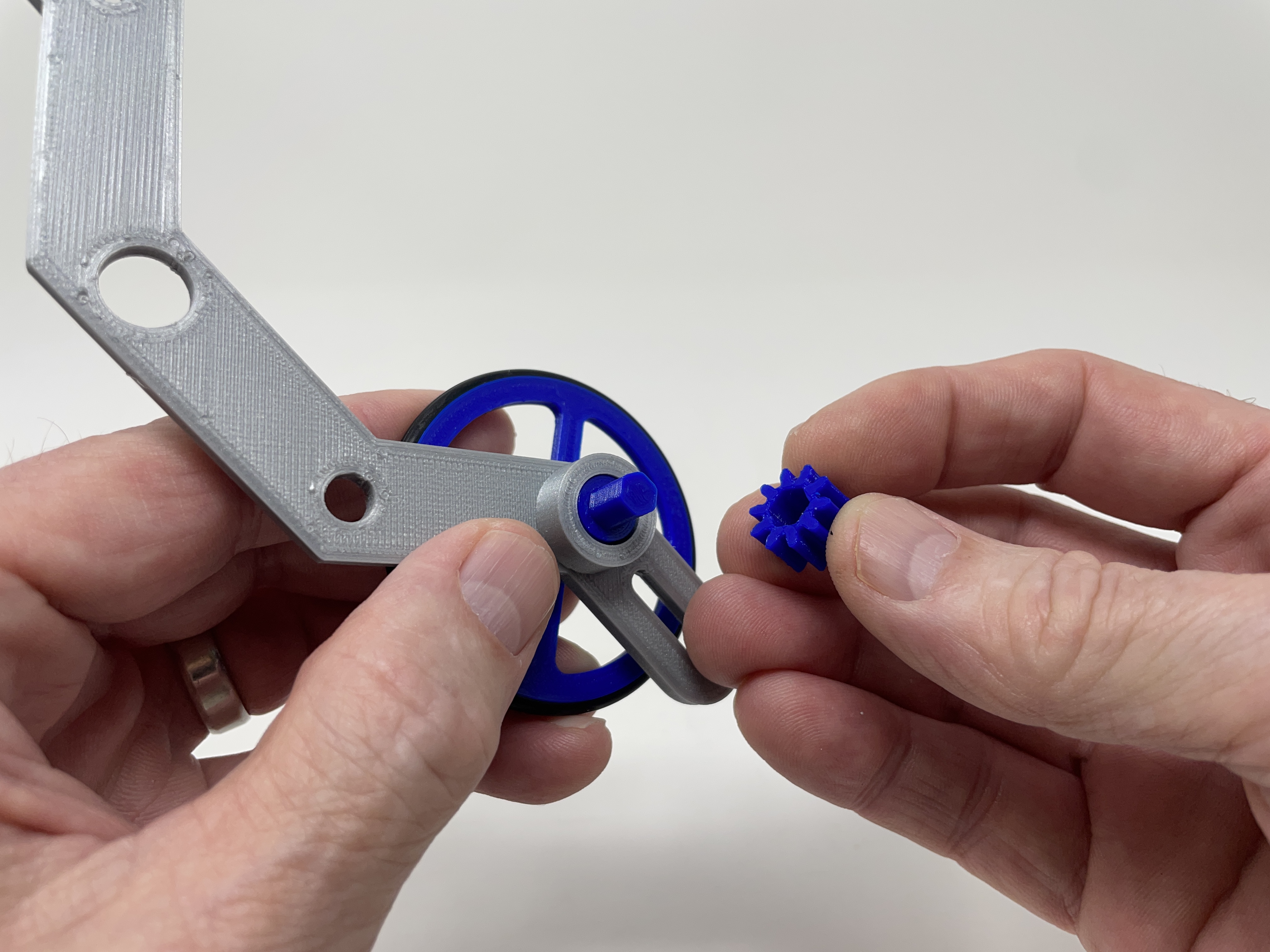

• Slipped one large O-Ring over one "Wheel, Rear.stl".

• Slid the wheel into "Frame, Left.stl", then secured the wheel in place using one "Gear, Axle (1.12m, 10t).stl", making certain the wheel rotated with ease.

• Repeated the previous two steps with the remaining O-Ring, rear wheel, and "Frame, Right.stl".

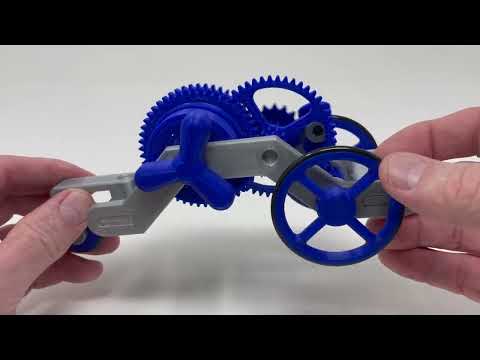

Assemble the Right Chassis.

To assemble the right chassis, I performed the following steps:

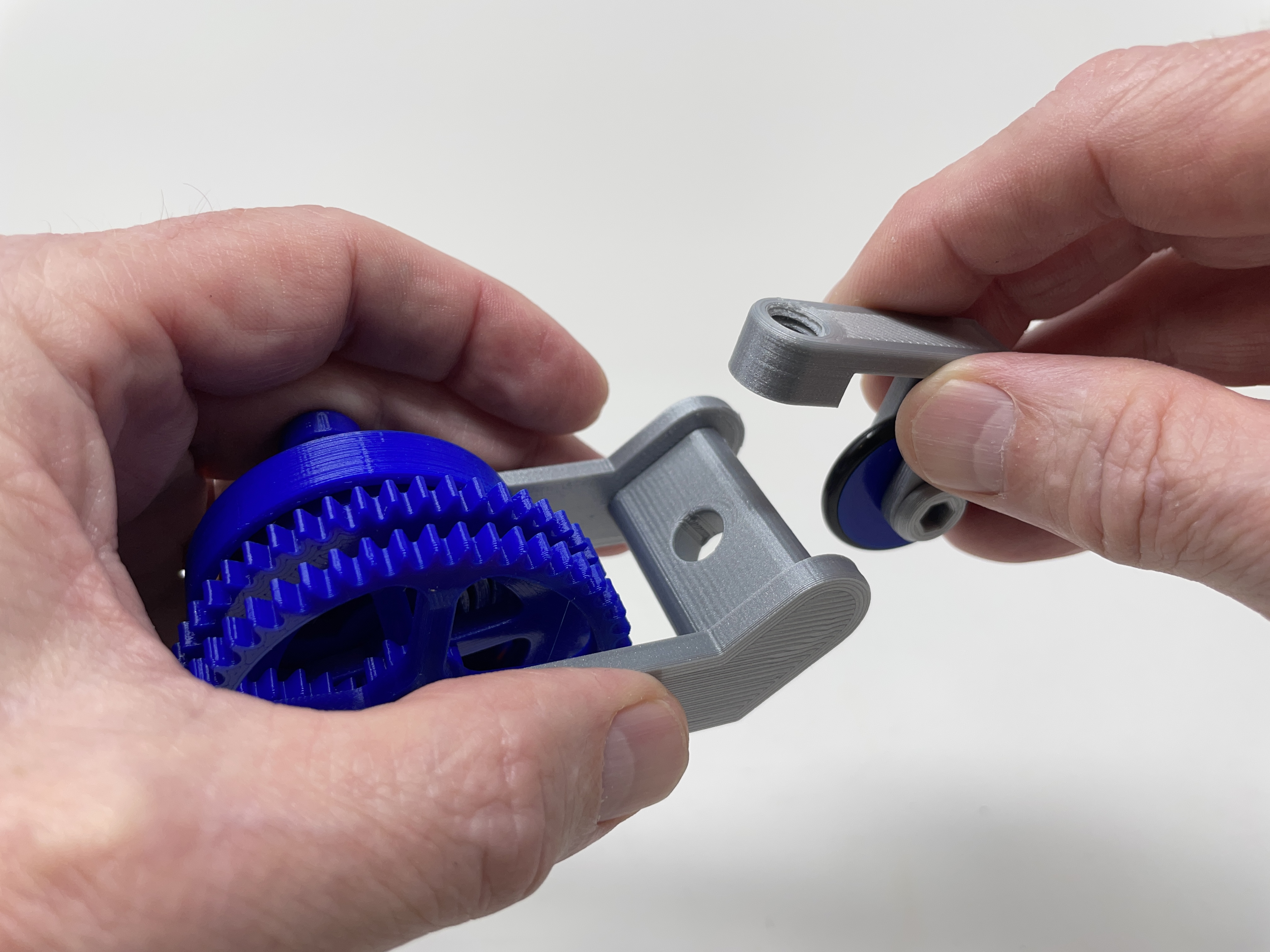

• Positioned "Pallet".stl" onto the right chassis assembly and secured it in place using "Axle, Pallet.stl", making certain the pallet rotated with ease.

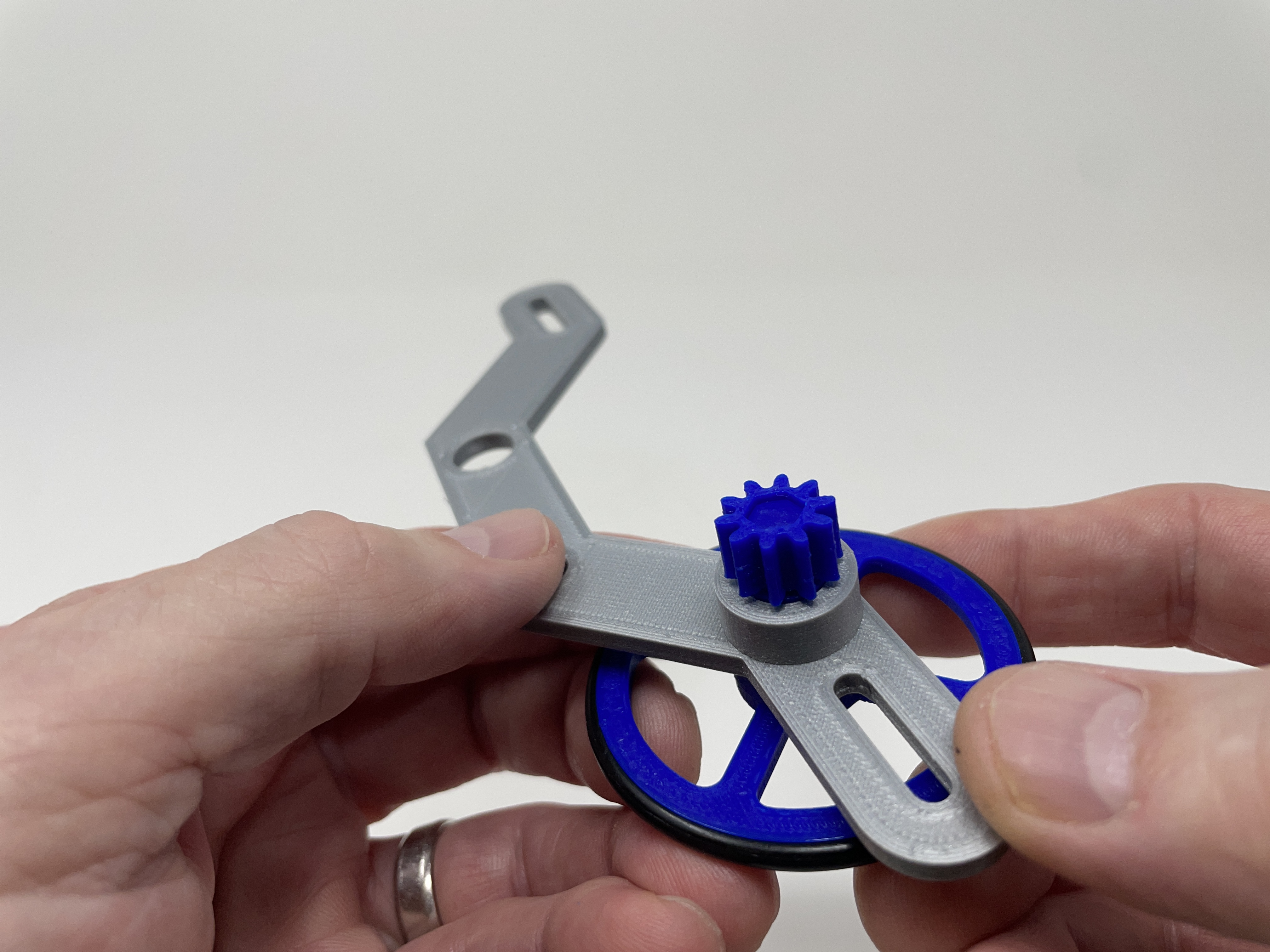

• With the pallet positioned as shown, slid "Escapement, Compound (1.12m 10t).stl" onto the right chassis axle.

• Slid one "Gear, Compound (1.12m 50t, 1.12m 10t).stl" onto the right chassis axle, making certain the compound gear rotated with ease.

Assemble the Left Chassis.

To assemble the left chassis, I performed the following steps:

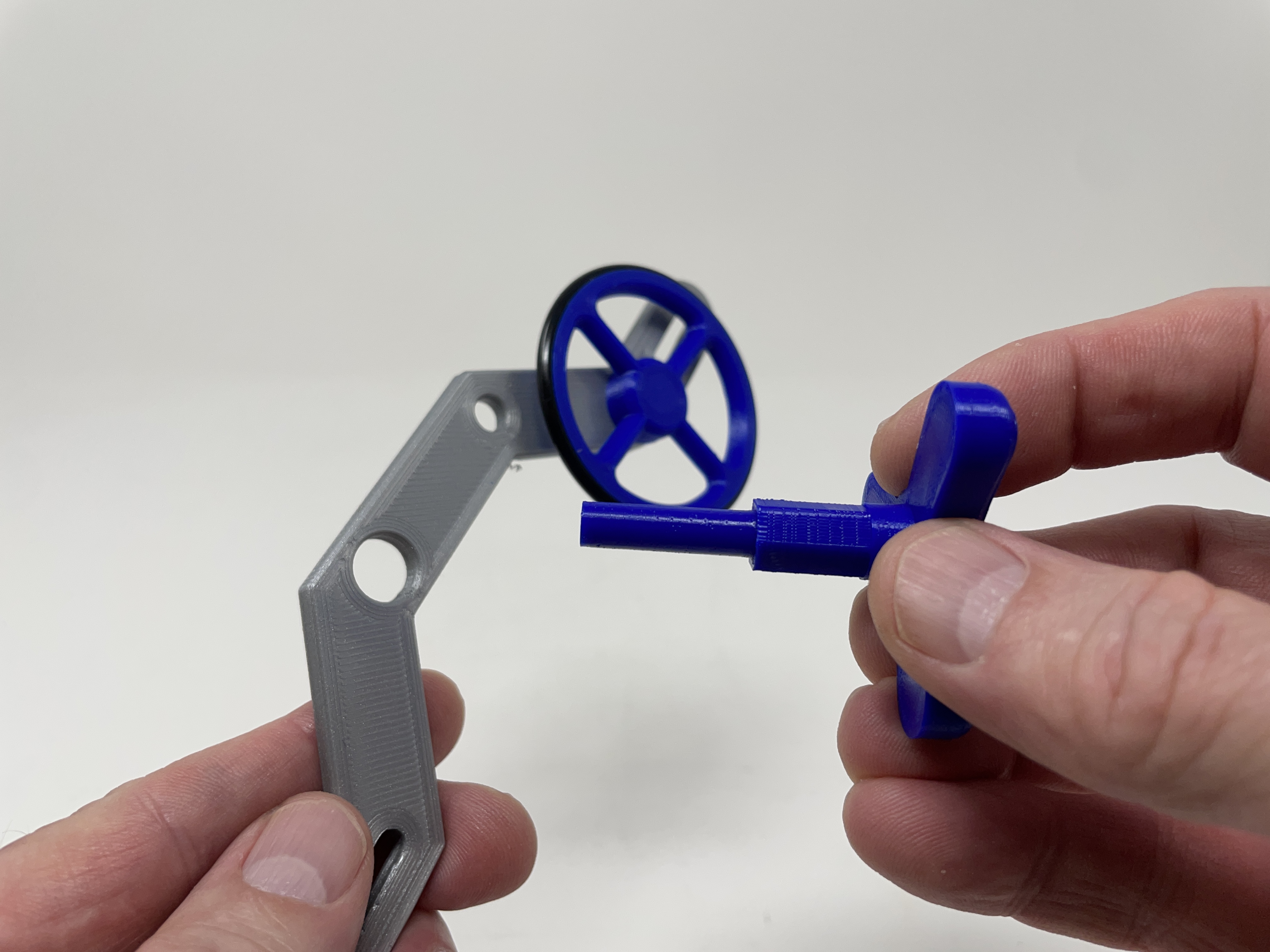

• Slid "Knob and Axle.stl" into the left chassis assembly.

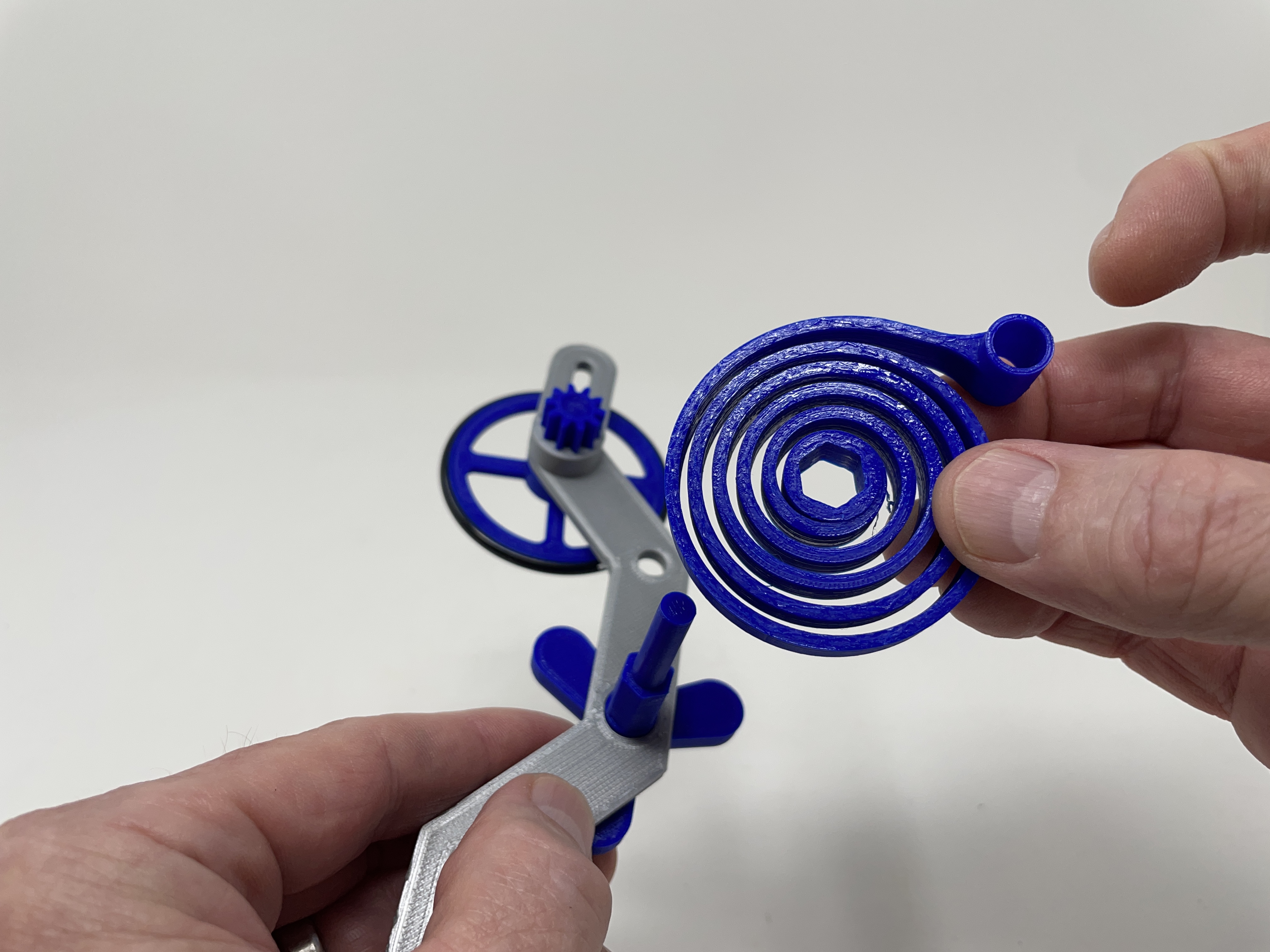

• Pressed "Spring.stl" onto the knob and axle.

• Pressed "Pawl.stl" onto the knob and axle.

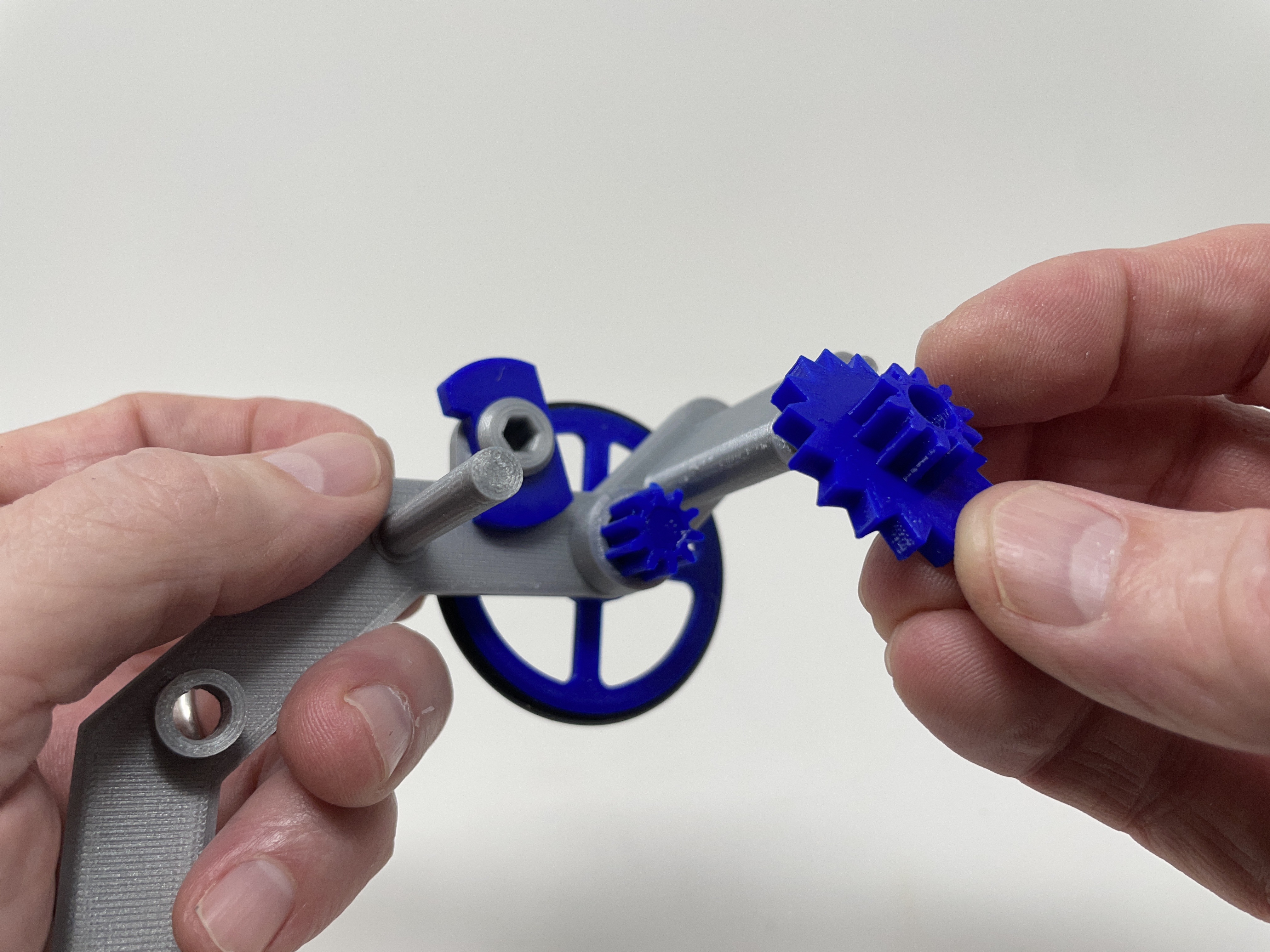

• Placed "Gear, Pawl (1.12m 50t).stl" onto the pawl.

Final Assembly.

For final assembly, I performed the following steps:

• Positioned the remaining "Gear, Compound (1.12m 50t, 1.12m 10t).stl" over the knob and axle hole in the right chassis assembly.

• Carefully positioned the spring end over the right chassis axle, the knob and axle through the compound gear and into the hole in the right chassis, then pressed the two chassis together.

• Slipped the small O-Ring over "Wheel, Font.stl".

• Positioned the front wheel assembly into "Tiller.stl", then secured in place using "Axle, Wheel, Front.stl", making certain the front wheel rotated with ease.

• Positioned the tiller assembly over the assembly, then secured in place with "Bolt (8M by 1.25 by 16).stl".

With final assembly complete, I positioned the tiller for straight travel, wound the spring, and let the vehicle loose. I measured around 12 feet before the spring energy depleted. Next I rotated the tiller to the left, wound the spring, and let the vehicle loose. By rotated the tiller to either side, the vehicle will travel in a circle. The further it is rotated the tighter the circle.

And that is how I 3D printed, assembled and tested "A 3D Printed Windup Car Using a "Runaway Escapement" Speed Regulator".

I hope you enjoyed it!

/https://fbi.cults3d.com/uploaders/13550170/illustration-file/04889aa7-a97d-4691-8a93-c517ec3e6247/Image00a.jpg)