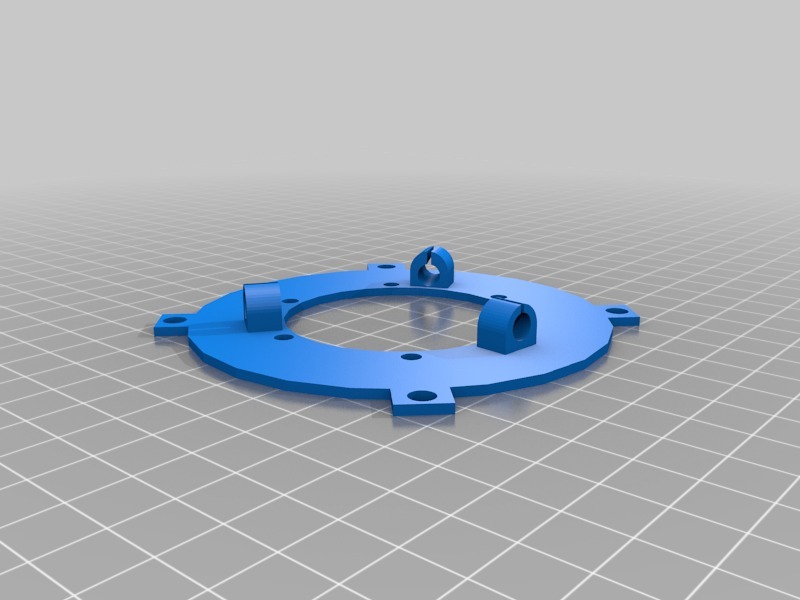

You can either build the entire monocle, or just the iris mechanism if you want. The only difference is that if you just want to test out the iris mechanism you don't print the monocle piece. This thing goes together in what you could call layers. You sort of sandwich the parts together.

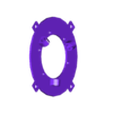

1) Print RingWHolesAndMount.stl

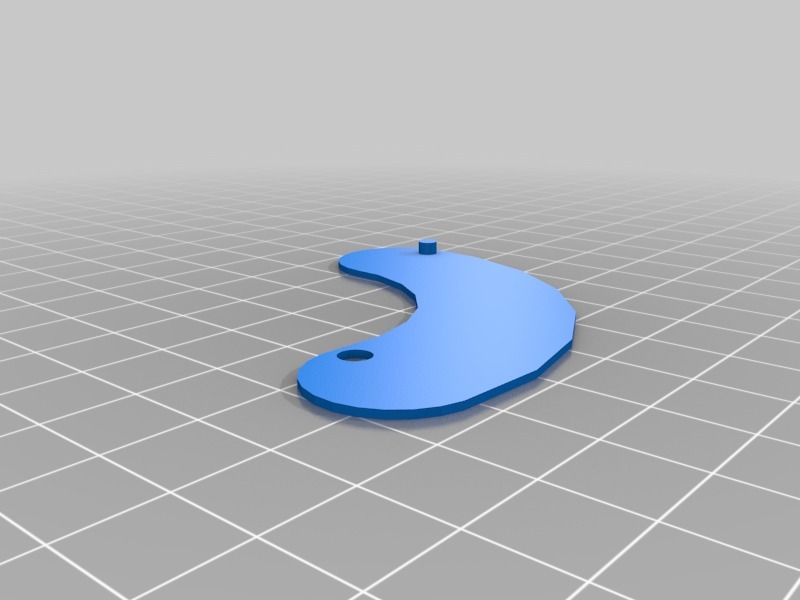

2) Print 6 of the FlapWstub file. I have included FlapWstubX3 so you can print three in one print if you want. However you do it, you need 6 in total.

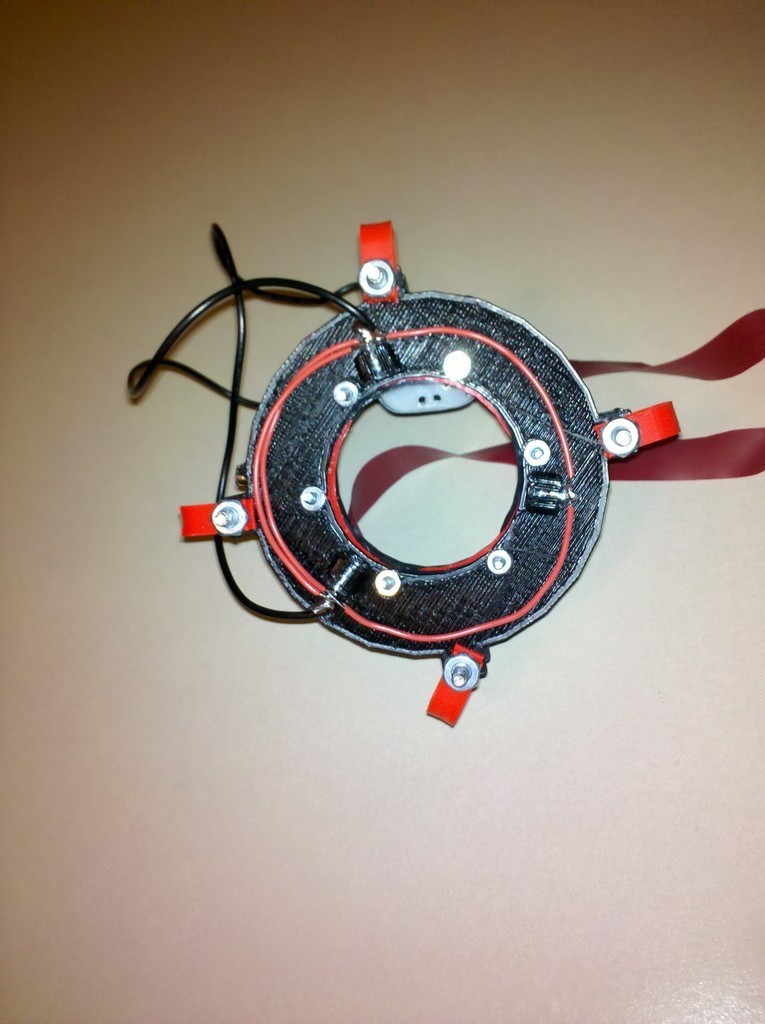

3) You need to attach the flaps to the RingWHolesAndMount. They attach to the side that does not have the LED mounts. You need to use small screws that have low profile heads. I used #4-40 1/2" machine screws I bought from Home Depot. Insert the screws so the heads are against the flap and the screw pokes out of the ring. The flaps have little pegs that need to be facing away from the ring.

4) Once all of the flaps are attached, arrange them so they are flush with the ring. Each flap should go on top of the next one, all the way around.

5) Now take the monocle piece and thread four larger screws through the four mounting holes. You want the screws to poke out away from the person who will be wearing this thing. This step is optional. If you just want a working iris mechanism to play with and don't want to print the monocle, you can just skip this step.

6) Print TestingRing.stl. You may have to clean up the circular slot so there are no strings inside. Strings will make the mechanism rotate poorly.

7) Slide the TestingRing onto all four screws. The side that has the circular slot needs to face away from the monocle. Slide the TestingRing down so it is flat against the monocle.

8) Print RingWithSlots.stl. Again, clean up the slots so everything will slide nice and easily.

9) Slide RingWithSlots onto all four screws so the pegs fit into the circular slot on the TestingRing. The slots on the RingWithSlots should be facing away from the monocle.

10) Slide the RingWHolesAndMount onto all four mounting screws. Make sure the flaps are sandwiched between the rings. As you slide this ring on, rotate the flaps so their pegs fit into the slots on the RingWithSlots. If they seem too large to fit, you may have to file/sand them down so they fit in.

11) Print Spring.stl.

12) Slide one spring onto each of the mounting screws. These springs provide constant pressure to the outer ring. When you rotate the RingWithSlots, the flaps press against each other and the outer ring wants to be pushed out. These springs allow the ring to move outward, but also move back inward. They aren't strictly needed but they help the mechanism work a lot more smoothly.

13) Place a nut on each mounting screw and screw it down so there is slight pressure on each spring.

You should be done now. The RingWithSlots is the one that you rotate manually. There is a small nub sticking off of the side that you can grab onto and use to rotate the ring. If it isn't working correctly, make sure all of flaps have their pegs sitting in the slots on the RingWithSlots. Slowly rotate the RingWithSlots and make sure that none of the flap pegs are falling out.

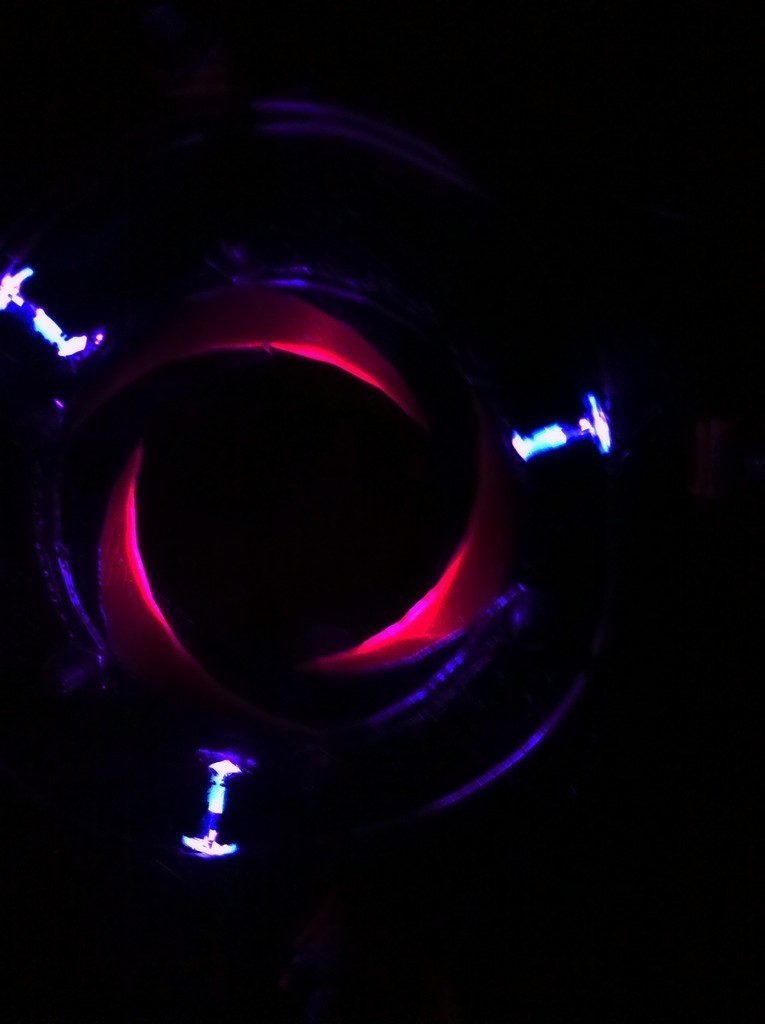

If you want to mount LEDs on this, you can slide them into the LED mounts on the outermost ring. I used 5mm LEDs and had to carve out a bit of the mounts in order to get them to fit. They fit nice and snug now. I wired them up in series and have a small 2AA battery mount taped into the side of the monocle. There is plenty of room for it in there. I might modify the monocle to include a holder for the batteries, I just don't want to do another 3 hour print.

For a strap, I used a pilates resistance band and just cut it to size with scissors. Then I tied it to the monocle piece where the band slots are. It seems to work well, although it has a very distinct rubber smell.

/https://fbi.cults3d.com/uploaders/16222341/illustration-file/0c426ce3-4508-4945-86de-042f5fdc7138/IMG_20110426_225121_display_large.jpg)