This is not an all inclusive "How-to" but rather an explanation of how I made and assembled the rifle. This airsoft gun is rather advanced and is not simple to make. It will require a lot of modification, mechanical ingenuity, plenty of airsoft teching experience and general DIY'ing patience.

The base of this gun is the Classic Army M132 HPA powered microgun. The first thing we need to do is disassemble the gun and remove the trigger handle, carry handle, and green gas bottle tube. The motor and battery tube will also be removed and cut down so that it only holds the motor as the battery will be relocated into the stock. On the back of the gun, you will see one air fitting at the top and two at the bottom. Remove the two at the bottom as they are not needed, they feed and internal expansion chamber for green gas and they will just be getting in the way of mounting the solenoid.

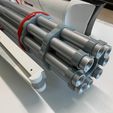

Start by adding the fake barrels to the front of the gun. Use the 3 different Barrel Rings to hold one of the carbon fiber tubes between each of the microgun’s barrels. Spacing of the rings is up to you but the front ring should be flush with the muzzle end off the tube. The microgun barrels and the carbon fiber tubes do not have the same outside diameter so if its not fitting move the to the next hole and it should work. The muzzles are the same way, you will need to print 4 of the Fake and 4 of the Real muzzles. This is because the internal diameter of the microgun barrels are not the same as the carbon fiber tubes. The Real muzzles go on the aluminum microgun barrels, and the 4 Fake muzzles go onto the carbon fiber tubes. The muzzles should be a snug fit and can be fixed in place with a little glue. The 3 barrel rings have a small hole in the side that you can thread a M3 screw into the to apply a little pressure to the ammo tube to keep them in place. Do not drill into the ammo tube!

Next we will build up the frame by attaching the solenoid to the Back Support and then bolting it to the back of the of the microgun. The Front Support ring can be slipped over the front of the gun and both front and rear supports can be bolted to the ¾” aluminum tube. Everything on the gun is attached to this tube, it is the spine of the gun. Moving towards the rear of the gun from the Back Support you can add the trigger halves on the bottom in a spot that you deem comfortable and then add the Bottle Mounts to the top at a distance that will allow good support of the HPA bottle. The Bottle Mounts have slots in them that allow you to run a zip tie around the bottle to hold it in place. With the trigger and bottle in place you can mark out spots both in front of and behind the bottle that can be safely cut away to permit routing electrical power and air lines through.

The stock is the most difficult part. I free handed the shape to match the game rifle as best as possible and cut out two copies of it from the ¾” PVC board. From here it is a bunch of work on the router table. A deep rabbit will need to be cut out into both halves of the stock to allow the aluminum tube to sit down into it and be bolted together from both sides. From here you will need to cutout extra pockets to allow room for the various supports, trigger, and battery. You can place the battery anywhere you like in the stock so long as you carve out a big enough hole. I choose to mount mine below the air tank as there were already holes in the aluminum tube that I can use to route power. Depending on the battery you use and how you mount it you may need to extend both the power and balance leads to make it possible to charge the battery without having to disassemble the stock to get to the battery.

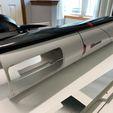

To make the cover for the gun start by cutting out a 1.5” slot down the length of the tube. This wil need to be opened up in some spots to clear the mounts on the aluminum tube but this will need to be done slowly as you want the pvc tube to naturally clamp down to the gun and for a snug fit. From here you can bolt on the Butt Stock and check for fitment around the regulator. You’ll notice a nice deep pocket in the Butt Stock, this is there for the regulator, if it hits just rotate the HPA tank and reg so it fits onto the butt stock cavity. With it fitting well you can cut the pvc tube to length, it should go all the way up to the base of the motor mount. To make it a bit more aesthetically pleasing I added another section of the 4” pvc pipe to the top of the body and cut out a windows on both sides, similar to how it looks in the game.

The last two pieces to add are the Front Bumper and Butt Stock Stop. The front bumper just presses into the front of the aluminum tube at the muzzle end and caps off the tube and rounds off the front of the stock. Both the Butt Stock and Butt Stock Stop have a small round pocket in them that you can glue a 12mm magnet into. Make sure they are oriented so that they attract each other. The butt stock stop is bolted to the top of the aluminum tube at the rear of the gun so that as the cover is slid into place it attracts the butt stock magnet and helps keep the cover of the gun in place.

Finally, all that is left is to plumb up the air and finish the wiring. The solenoid is directional so make sure air from the regulator goes into the “IN” side on the solenoid and line from the “out” side is routed to the one fitting at the top of the gun that we left in place. You will need to use various pipe fittings to make sure the airlines are routed with as little tight turns as possible as tight turns will make the macro line kink. Using the original wiring from the microgun, splice into the lines going to the motor and wire the solenoid in parallel. That way when the trigger is pulled the mosfet sends power to both the motor and solenoid at the same time. To add a safety simply add a switch between the battery and the mosfet, this ensures both air pressure and electrical power are turned off when the safety is used. The placement of this switch is completely up to you. I mounted my safety switch on a piece of bent aluminum underneath the solenoid that can be reached in a small gap between the cover and stock.

Go as crazy or a simple as you like with the paint job!

Parts Required:

Classic Army M132 HPA MicroGun

Ninja Carbon Fiber 45cu 4500psi HPA Tank

Wolverine Regulator

¼” 12V Solenoid

20X330mm Carbon fiber tubes (X4)

11.1V 1200mAh Lipo Battery

SPEED Trigger (V2)

6mm Macro line and press fittings

4” PVC Tube

3/4” PVC board or similar

¾” Aluminum square tube approx. 910mm long

12mm neo magnets (X2)

Others:

Misc wires, connectors and air fittings

Assorted M3 hardware and zip ties

/https://fbi.cults3d.com/uploaders/24018693/illustration-file/94954430-8e79-4f15-9302-768ab146ffee/1.jpg)