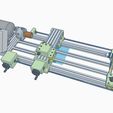

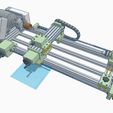

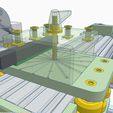

Well, this is the r2.0 version of my lathe, only handly driven, but easely portable to CNC.

- Into provided CNC.ZIP you'll find all items needed to build the CNC version.

- Items in STEP and F3D format are provided for both versions.

As usual, buyers can request the link to the whole project at Tinkercad.com.

First alignment video here: https://youtu.be/TfO16oEG1MU

Second video with CNC wotking here: https://youtu.be/YZiykR4ji8k

Third video here: https://youtu.be/6G-Da1S9fOc

Fourth video (cold CNC test) here: https://youtu.be/pcWi-et-hy8

UPDATES

2022-07-05

- For brave hearts only; added a experimental rotating turret, 360° in 22.5° self-locking steps. All necessary items and instructions in ROTATE.ZIP.

2022-07-10

- uploaded 3BUTTONS.ZIP with Arduino UNO sketch to drive the Z stepper manually via 3 buttons.

2022-07-13

- uploaded Z_AXIS_CARRIAGE_BASE.STL, aimed to reinforce carriage robustness

2022-07-16

- uploaded brand new software LCD_GRBL_MEGA_2AXES.ZIP implementing LCD 2004 and SD card (see fourth video above).

Thanks to Carlos Guerrero https://github.com/cguerrero1205/LCD_GRBL

and Bart Venneker https://github.com/bvenneker/Arduino-GCode-Sender

for their wonderful work!

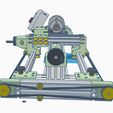

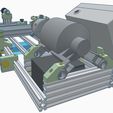

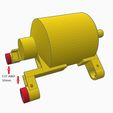

As previous version, it uses an easy to get motor from faulty washing machines; at today they're almost all BLDC (Brush Less Direct Current) equipped, very similar as concept to the stepper motor we're used to.

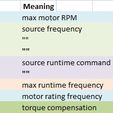

The motor I use is an Ignis WM (Nideco motor) and needs 195VDC at 310Hz for max power and speed, but it can be driven with a lower frequency (less speed and without almost any loss of its 600W power); I opted for an VFD 220V 0-400Hz 1,5KW and 50Hz seems to be good choice for speed.

Furthermore it features wonderful bearings, engineered for big radial charge, perfectly balanced rotor and, last but not least, a very quit operation.

If you however don't like BLCD motors, you can always a motor of your choice and provide it with adequate suppports and driving method.

This lathe features:

- main carriage knob to intuitive movements, 2.5:1

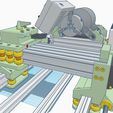

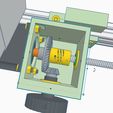

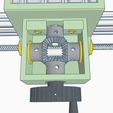

- reinforced and dust protected tool carriage with C-Beam profile, two sides driven

- continuously variable speed via a cheap VFD BLDC controller

- fixed tools turret with two insertion sides, 0° and 90°

- optional rotating turret 360° in 60° clicking steps

- tailstock carriage sliding with manual action, lockable in place

- can accomodate also every printed 80mm chuck

- max workable length 500 mm (with tailstock, of course...)

- very few printed items

NEW

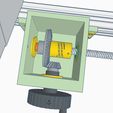

- LCD2004 and SD card to work from files or manually move the axes (n. 1 Arduino Mega, encoder KY-040 and Arduino MicroSD card adapter)

Exploded views STL included.

I hope you like this too...

INSTRUCTIONS

Motor:

- cut away 10mm from back foots (see red parts in picture above)

- put it exactly at center of profile and place the 4 foots

- move the tailstock close to the chuck and align the chuck center to it

- tight firmly the motor and the four feet screws

- apply the 19-14mm adapter to the motor rotor

- screw in the chuck adapter plate

- with spinning motor ensure that there's absolutely no oscillation

- tight the two 19/14 adapter grubs enough to let a mark on the rotor

- remove the adapter from motor and with a 4.5mm drill bit make a little conical hole 1mm deep to each mark on the rotor, to fit the grub points

- apply again the adapter and tight well the grubs

- check again with spinning motor that there's absolutely no oscillation and eventually correct

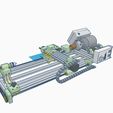

CNC

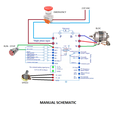

Manual operation:

It's only necessary cut off the power to the controlling board...

Firmware:

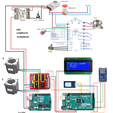

brand new based on GRBL 1,1h, implements LCD 2004 and SD card wich lets you work directly from SD or manually move axes.

BOM

Electronics:

manual version

- n. 1 washing machine BLDC motor

- n. 1 button self-locking switch

- n. 1 safety switch

- n. 1 cheap VDF 1.5KW 3 phase controller

- n. 1 SSR relay in 220/380 out 220/380

- n. 1 10KOhm linear 10 turns potentiometer

CNC version

- n. 1 washing machine BLDC motor

- n. 1 button self-locking switch

- n. 1 safety switch

- n. 1 cheap VDF 1.5KW 3 phase controller

- n. 1 SSR relay in 220/380 out 220/380

- n. 1 I2C LCD 2004 display

- n. 1 Arduino Mega 2560 board

- n. 1 Arduino Uno board

- n. 1 Arduino Uno CNC shield

- n. 1 Arduino MicroSD module

- n. 1 KY-040 encoder

- n. 1 ON-OFF switch

- n. 2 Nema23 steppers

- n. 1 12VDC20A power supply

- n. 1 40mm fan 12VDC

- n. 2 hall proximity sensors

- n. 2 8x3mm Neodymium magnets

- n. 1 10KOhm linear 10 turns potentiometer

Mechanics:

- n. 1 K11-80 chuck

- n. 1 14mm base for K11-80

- n. 1 19mm to 14mm adapter for above chuck

- n. 1 Makita 9523 gears set, very cheap

- n. 4 Bevel gears 1.5 Modulus 20 teeth 8mm bore

Body:

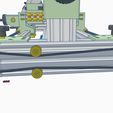

- n. 1 C-Beam profile 4080 308mm

- n. 2 profiles 2080 230mm

- n. 1 profiles 2060 230mm

- n. 2 profiles 2060 70mm

- n. 2 profiles 2040 1000mm

- n. 2 profiles 2040 175mm

- n. 2 profiles 2020 807mm

Bearings:

- n. 13 608ZZ bearings

- n. 2 F6900ZZ bearings

- n. 11 M5 spacer 6mm

T8:

- n. 1 T8-2 leadscrew 770mm

- n. 1 T8-2 leadscrew 580mm

- n. 1 T8-2 leadscrew 350mm

- n. 4 T8-2 round nuts

- n. 1 T8-2 T type Opensource anti-backlash nut

Rods and bars:

- n. 1 M10x135mm threaded rod

- n. 2 rod 8x65mm

- n. 2 rod 8x45mm

Wheels:

- n. 1 threaded hex coupler M10x32mm

- n. 28 24mm Delrin wheels

- n. 14 5mm eccentric nuts

MISCELLANEOUS

- n. 1 safety switch

- n. 1 T2 loop belt 810mm

- n. 2 T2 belt timing 60 teeth 44mm OD 8mm bore

- n. 2 no teeth pulleys 5mm bore

- n. 1 5 to 8mm flexible coupler

- n. 1 10mm socket drill chuck

- n. 31 90 degrees profile locks

- n. 8 8mm collar locks

- n. 1 M10 nut

- M5 flat head screws screws

- M5 nyloc nuts

- t-nuts

/https://fbi.cults3d.com/uploaders/15451373/illustration-file/bffc9dac-309c-4a38-b26b-f02b3904ae7b/1.jpg)