Please download the files individually to ensure you got the correct files. Some people are having trouble using the download all from thingiverse.

Facebook group: https://www.facebook.com/groups/SpringThunder/

Assembled blasters available here: https://www.etsy.com/shop/GDop26

Custom colored blasters available from our friends at frontlinefoam: https://frontlinefoam.com/product/spring-thunder/

Hardware kits available here: https://www.shellingtonblasters.com/product-page/spring-thunder-hardware-kit-model-5

Shells Here: https://www.thingiverse.com/thing:3210080

Stocks: https://www.thingiverse.com/thing:3129063

Sling Point: https://www.thingiverse.com/thing:3144712

Assembly Guide: https://www.shellingtonblasters.com/assembly-guide

Troubleshooting guide: https://www.shellingtonblasters.com/trouble-shooting-guide

~~~~~~~~~~~~~~ Updates ~~~~~~~~~~~~~~~~

(2-19-2022) Shell Align Update

New shell align part uploaded, which aims to improve feed rate and decrease the jam type where the shell hits the side of the ejection port during chambering.

This issue has plagued the platform since nearly its inception in 2018, and this fix had been discovered during happen-chance diagnostics back in November 2021. It has now been in testing for 2-3 months and results seem to suggest a 50-70% reduction in this type of jam, as well as a generally smoother operation.

Installation of this part is a direct replacement of the old shell align, and no new hardware or steps are required for this update.

(11-15-2021) General Blaster Update

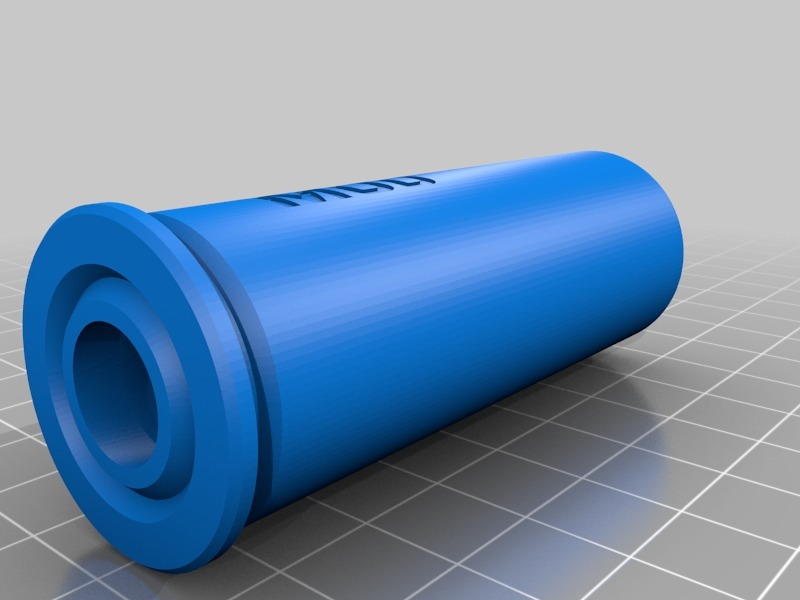

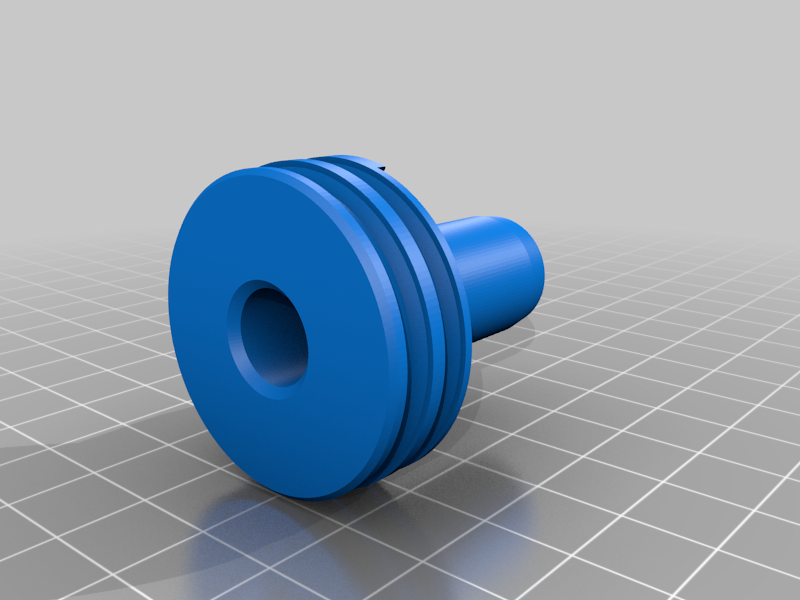

Plunger Seal - Seal screw removed. This is now attached to the bolt assembly with the same screw used to attach the shell-align to the bolt face. This reduces the hardware complexity as well as removes a point of air seal leak. We’ve been testing this new design for over 10 months, and are now pushing the update through.

Barrel Coupler - Revised to widen and realign the shell-align interaction on the bolt. This was sometimes causing interference with the bolt. The coupler's shell chambering shoulder was also thickened to improve its durability during general operations.

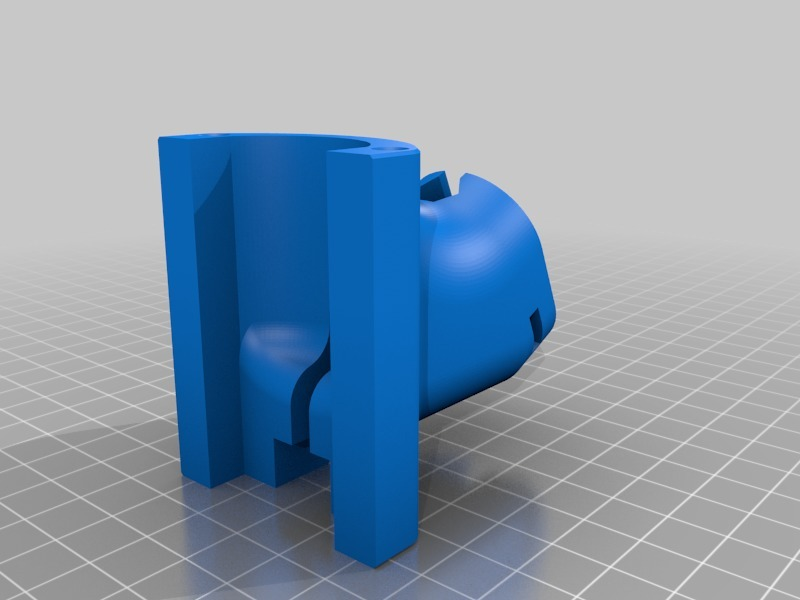

Pump Grip - Improved the durability of the pump grip by removing unnecessary complexity and therefore increasing amount of PLA used in the part.

Handle - Screws changed to a more standard size of 1.500” and cleaned up its look. 2 variants of this part have been uploaded. One with and without through holes, so that it can be used with older hardware kits that don’t have the newer 1.500” screws. The variant without the through holes uses the 1.500” screws and don’t have hole or cavities for 6-32 hex nuts sticking out the back of the handle. This is primarily an aesthetics and logistical change, and doesn’t affect the performance of the blaster.

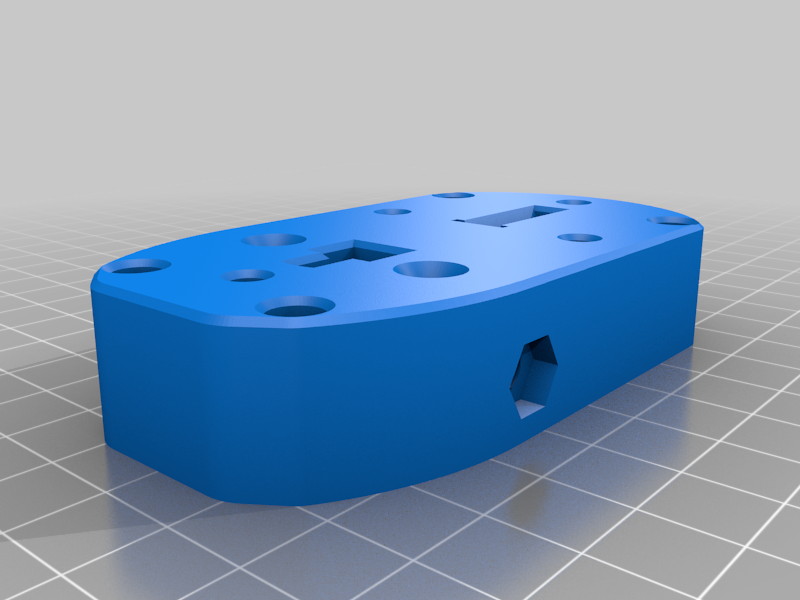

Spring Rest - Increased its sear clearance gap width to improve the allowable tolerance when installing the sear. The slots for the hex nuts were also removed and the assembly method changed to the newer standard of self tapping/screwing screws. The screws were also adjusted to the more standard length of 1.500”, though the old 1.625” screws still work here.

All files from the most recent previous update have been uploaded into a compressed folder marked as such.

(12-12-2020) New Plunger Head uploaded that takes the 311 sized O-ring as its shock padding.

R12_V1 is the new version that takes the O-ring

R11_V2 is the old one that takes the old shock pad

(11-26-2020) Uploaded a STEP file of the standard triple Rival Ball Buckshot shell. It is traditionally found with the rest of the shell files, but it makes sense to also include its download here.

(9-9-2020) Since transfer bars are 3d printed as a standard now, I have also uploaded their STLs here for anyone to print.

(8-22-2020) Big updates with the model 6 version of this blaster platform. I've been building testing the version for a few months now, so I think it's ready for public release now. The primary changes were made to improve durability of the firing mechanism and improve tolerances and ease of building.

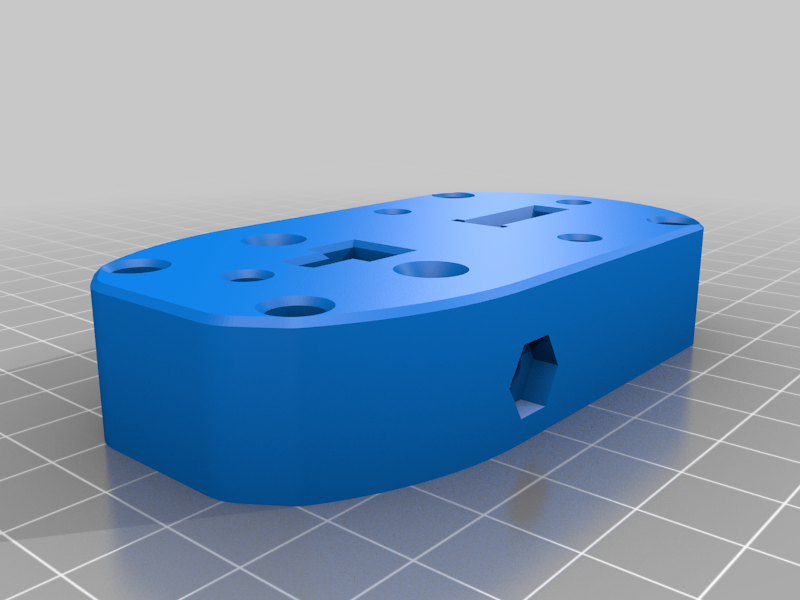

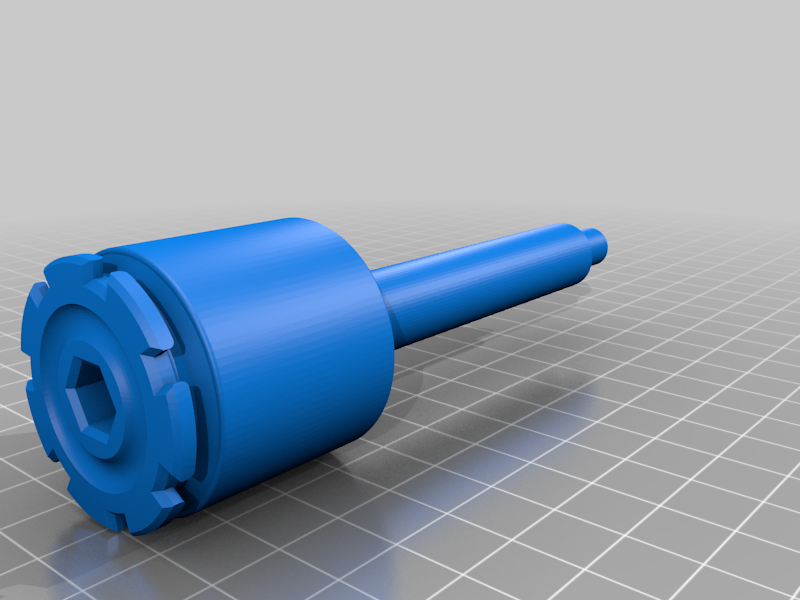

Plunger Head - The Nylon rod was replaced with a threaded rod and 3D printed composite fitted with a harder stainless steel washer. The washer replaces the machined nylon surface, which improves its hardness significantly to greatly decrease the rate of wearing on the firing mechanism. The use of the threaded rod with the 3d printed plunger assembly also improves sizer tolerances for a more consistent build. The entire assembly also happens to be about 9% lighter. Not sure if this has much of an effect on performance, but my understanding is that you want as light of the plunger head as possible for the fastest spring movement.

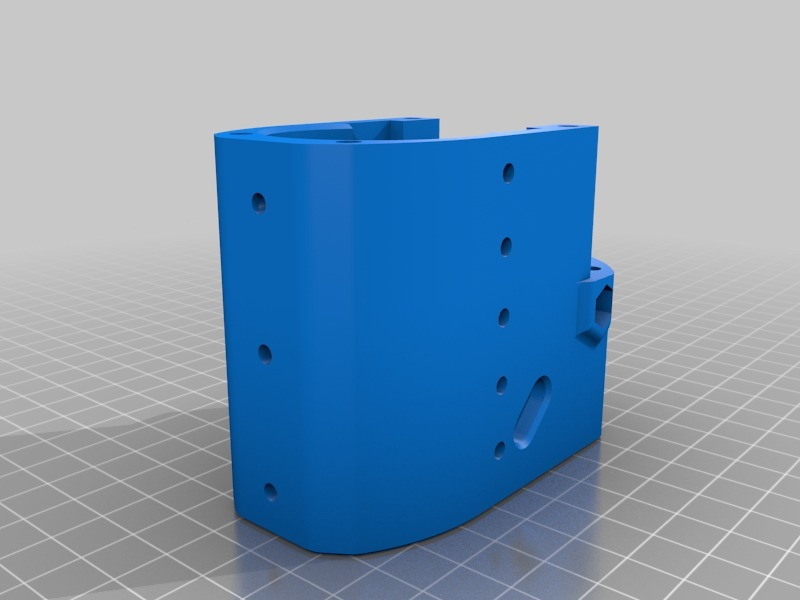

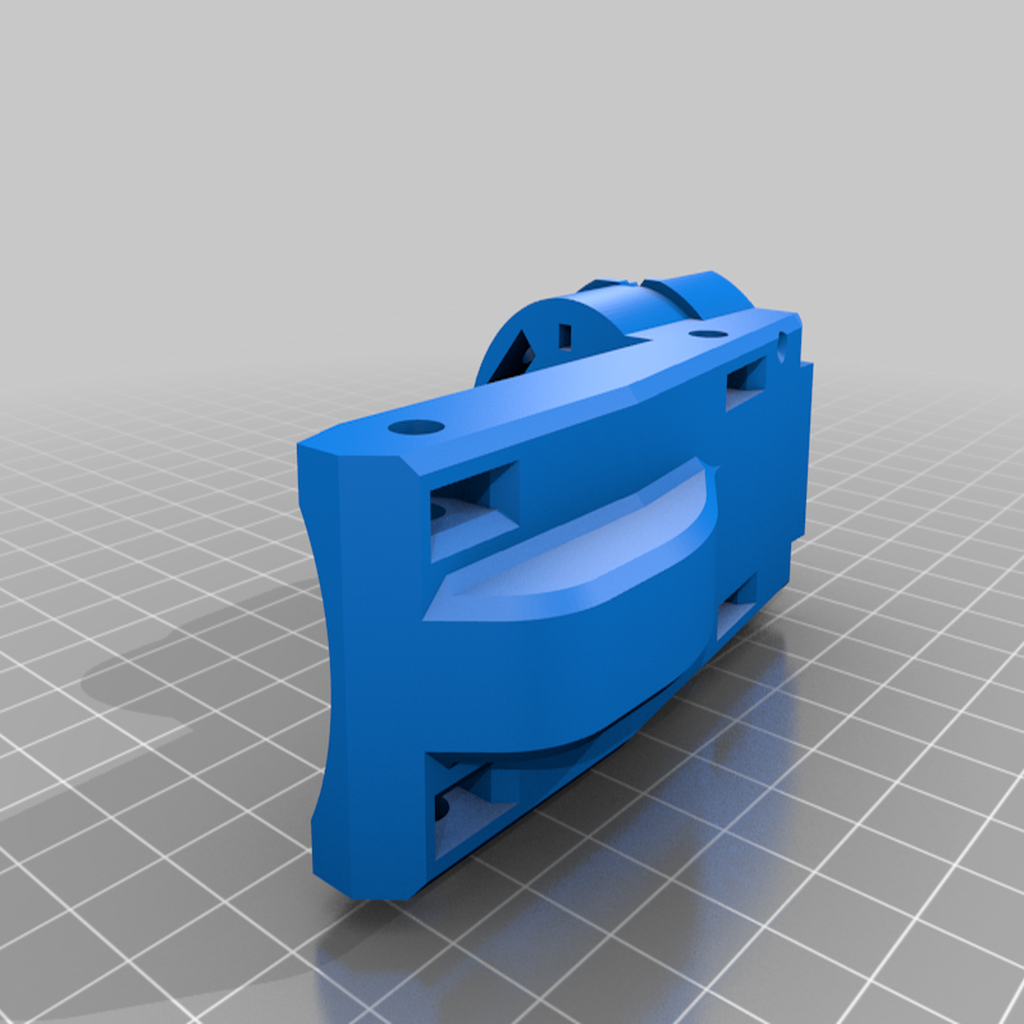

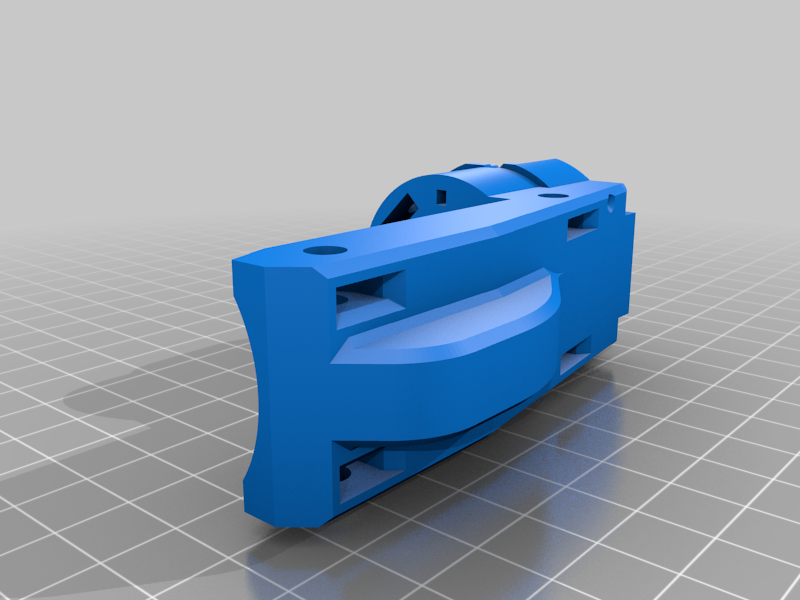

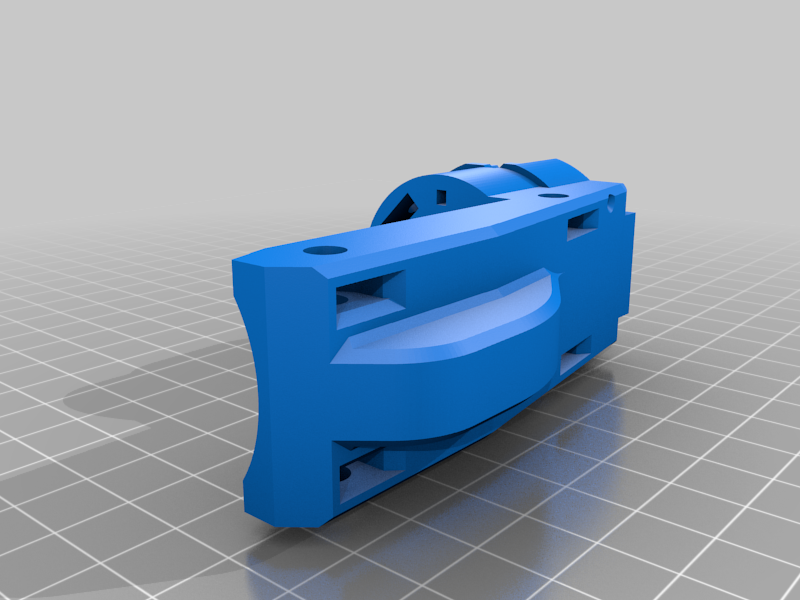

Bolt - Simplified assembly by removing nuts and screws for securing the plunger tube. It's a little more complicated in a different way. Instead of securing the plunger tube using screws, it is now held in by crimping/bending the aluminum tubing onto the 3d prints to literally hold onto it. Removal is harder, but assembly and fabrication of parts are much easier, which also improves the consistency of how I fabricate them.

Smaller changes include the Ejection Ports A and B - I removed the pin holes and replaced them with 3d printed alignment tabs. These were optional in the past to assist with keeping the parts aligned. But with the 3d printed tabs, you won't need to manually insert these pins anymore. Which technically also makes the blaster lighter haha.

(5/19/2020) Thingiverse keeps moving the thumbnail around making it harder to find this posting. I manually moved it back, hopefully it stays that way.

(2/9/2020) A few much needed updates following many months of testing and a couple hundred successful builds, leaving this update ready to pass. As well as some parts that I've forgotten to update for a long while. Sorry to all the people who've ordered and built kits for these last couple of months.

Plunger Seal - Divots added to allow the bolt assembly work with the longer 1/2" screws

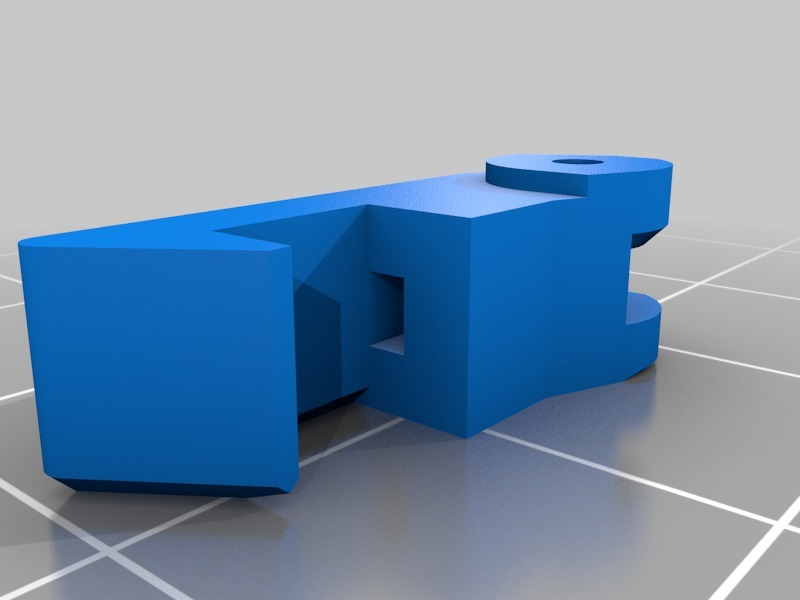

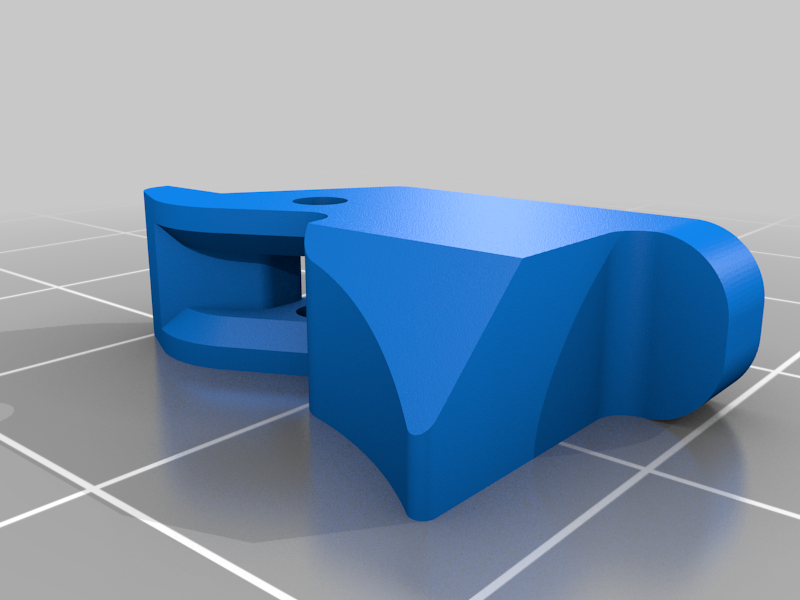

Shell Latch - this is a pretty big update, as the part has previously been unchanged for nearly 2 years of the project's development. The part was shifted by a bit to be more reliable with its activation by requiring less force to open while still retaining its holding power.

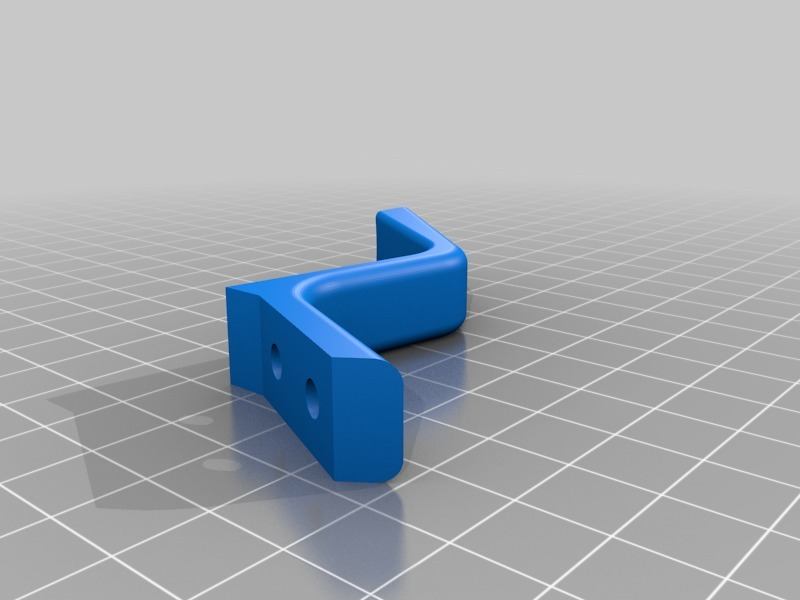

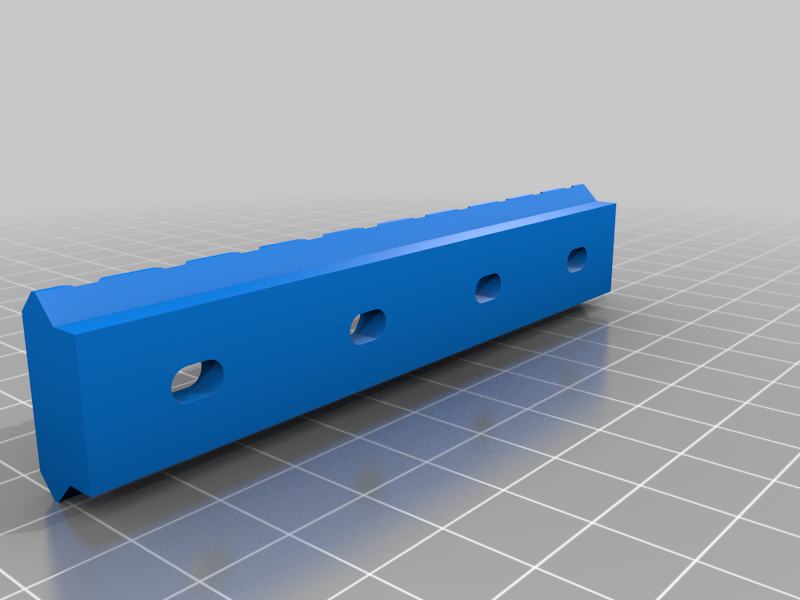

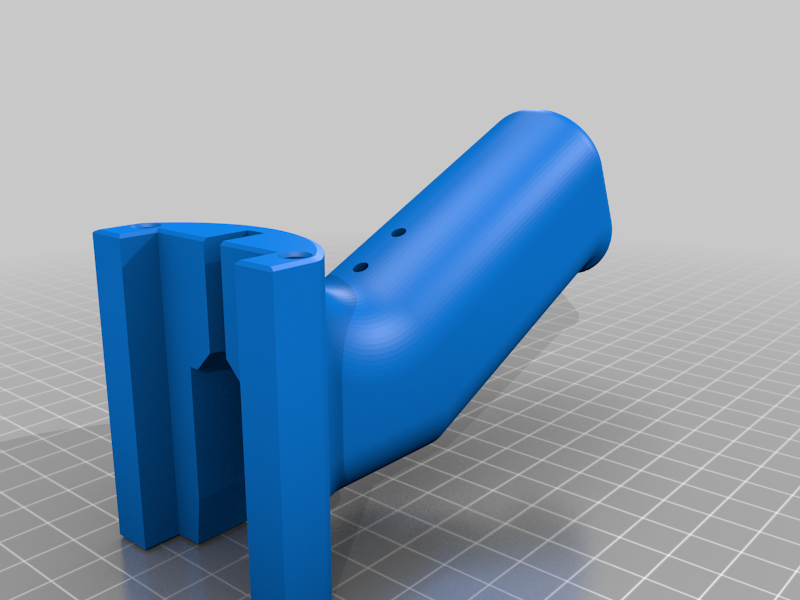

Back Plate - Added open slots for much easier installation of stocks and rear accessories.

(9/1/2019) Picatinny rail added, or rather I realized it was missing so now it's back.

(8/28/2019) Apparently the shell carrier was also missing. It's back and nothing is different about it I think.

(8/26/2019) Missing parts added

Apparently the back plate has been missing for some time, so I re-added it.

Bolt - revised with a larger groove for its sealing O-ring to make it easier to install. Its extractor cavity has been extended to better hold onto its extractor assembly. Its pivot pin hole has been expanded by about 0.010" to fit the assembly more easily.

(6/2/2019) Model 5 Released

Major update

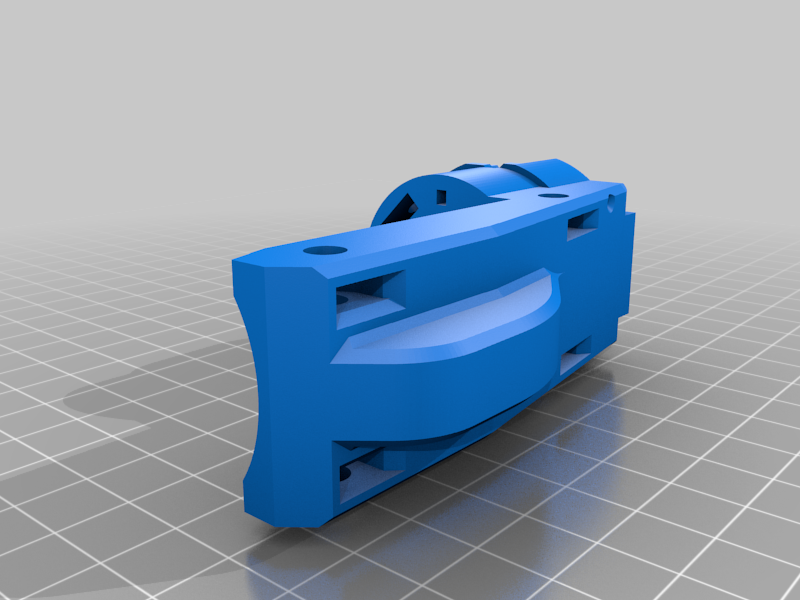

New Bolt: Model 5 introduces a redesigned bolt that allows shells without o-rings to be used effectively. This needs a rebuilt bolt and some new hardware and an updated assembly guide will be provided in the coming days. This was created to allow users to more easily create their own shells with less involved labor. Additionally, this bolt is backwards compatible with old shell designs allowing for shells with either O-rings installed or not.

In addition to the new O-ring set up, this update introduces a couple other significant improvements.

Extractor Durability: The extractor was redesigned to bend less during jams. This used to cause the spring to overbend and loose its spring back ability, now it bends 50% less which extends its life and resistance to being bent too far during jams.

Tapped Rails: A response to overwhelming complaints over the difficulty in installing rails, the top holes have been narrowed to allow picatinny rails to directly screwed into the plastic for low load applications. The hex nut cavities were untouched to be used for high stress and loads such as sling points.

Minor Updates

Shell Carrier: Much needed chamfers were added to relive the part of sharp edges.

Carrier Roller Chamfer: This was added to reduce cleanup needed for assembly.

Ejection Port: Relief angles were added to reduce supports needed. Pin slots were extended to improve pin retention for the shell latches.

Mounting Holes: Added to support future accessories

Plunger Bolt Seal: Seal screw assembly reduced to QTY 1 as second screw was deemed redundant. Very low loads are experienced here. Additionally, fewer fasteners used reduces points of leakages in the plunger tube assembly.

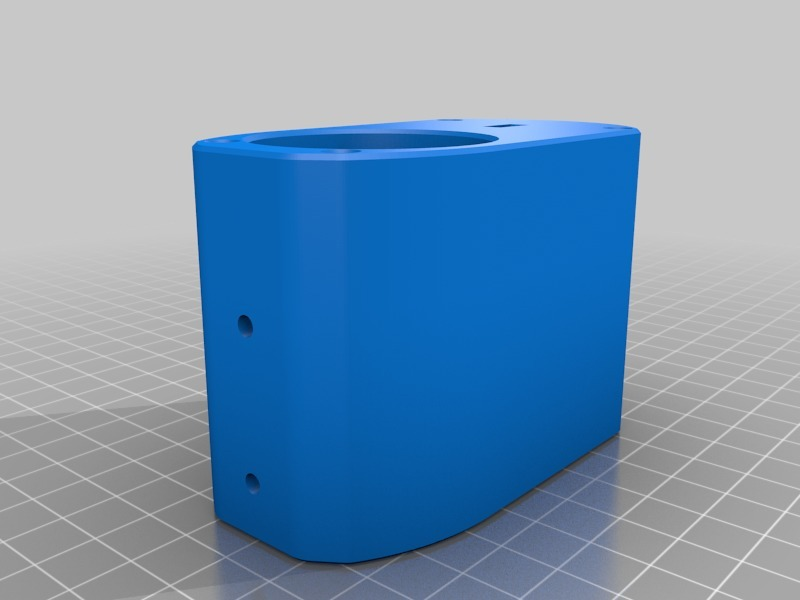

Handle: Single print handle available, reducing labor and improving print quality for those with larger printers.

Model 4 Files are saved in a zip for those with older models looking to repair. Though I recommend you switch to the model 5.

(5/5/2019) Extractor Durability Upgrade

New extractor will be more resistant to over bending by the spring. This should extend the life and function of the extractor.

(3/22/2019) Missing Files Added

A user pointed out that I missed the shell align file, so that was added.

I also uploaded the previous version's files for anyone looking to repair an old build. These can be found in the Model 3 zip.

(3/10/2019) Big Assembly Update

Okay, a little later than I'd thought but it's finally here. I rebuilt the assembly guide the correct way so I can actually make changes and updates to it later on and I uploaded the new files that I've been making blasters with for the past month or so, so I definately know they work.

Here's the new assembly guide, packed with accurate part descriptions this time: Assembly Guide: https://imgur.com/a/rTDnmiZ

Here's also a changelog of the updated 3D printed parts.

In General - Chamfers added to all edges to help with elephant footing. This shouldn't be very noticeable but will help with the buldge created by elephant's foot as well as reducing support needed.

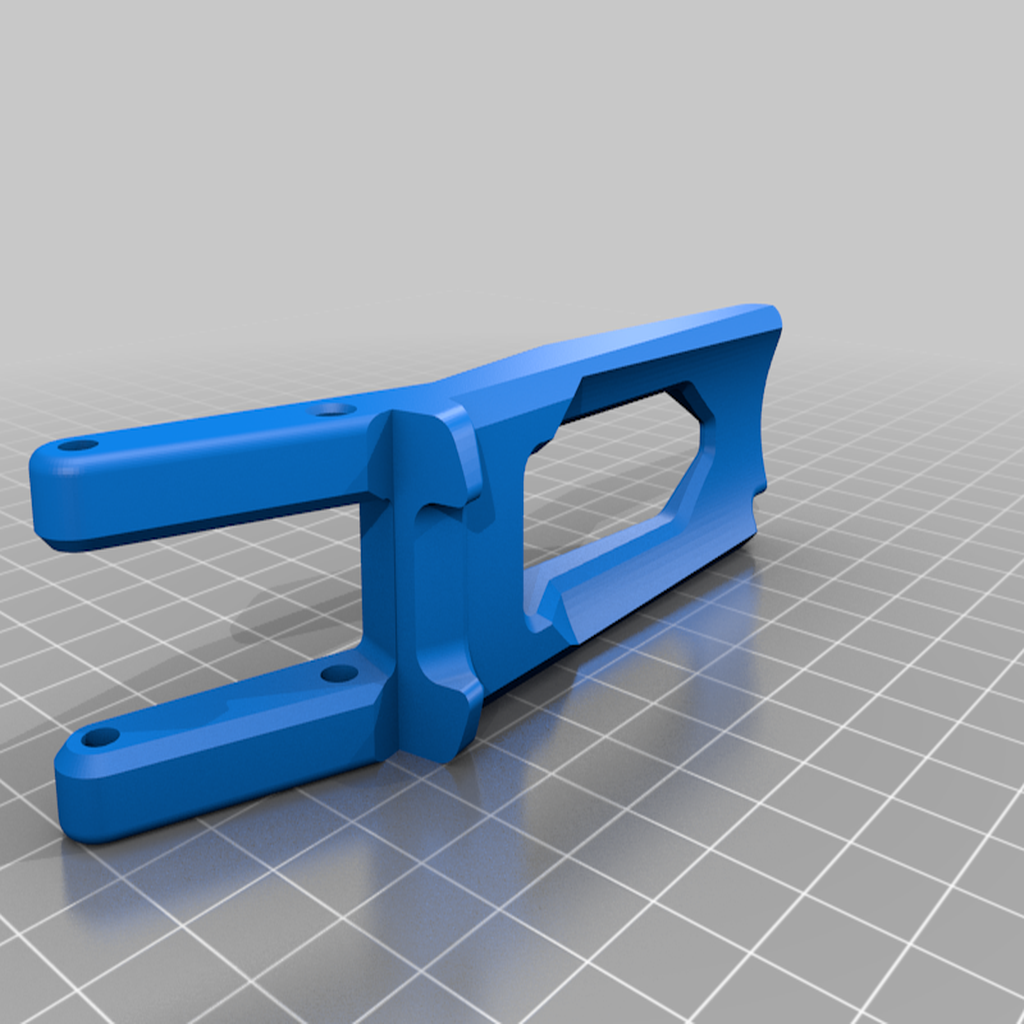

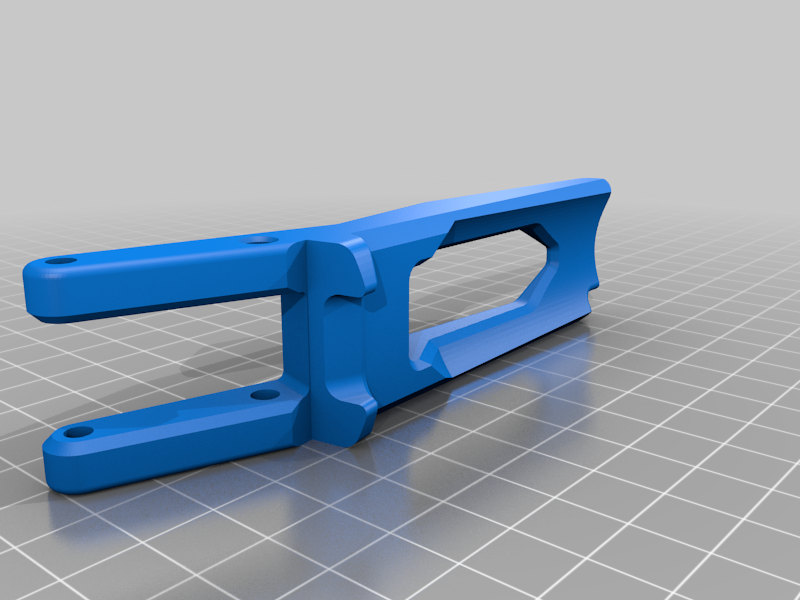

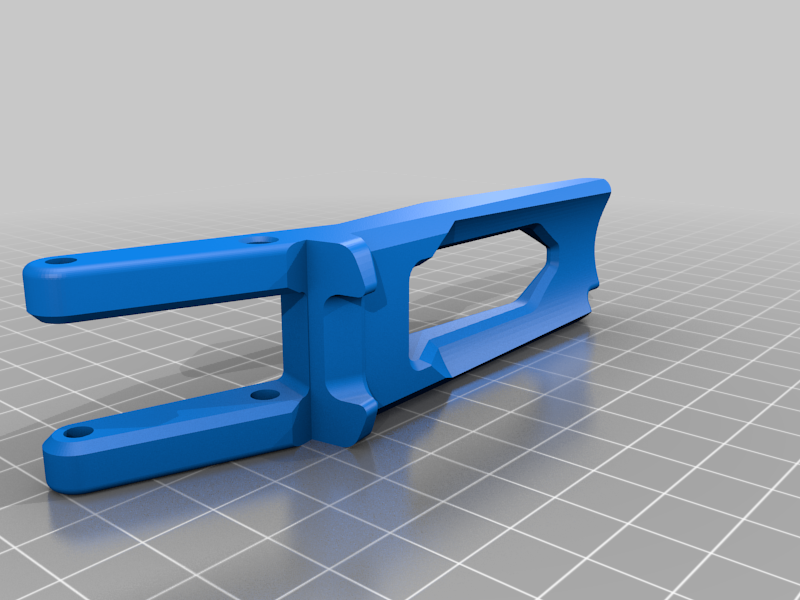

Bolt & Shell Align - These have faced the biggest change. Instead of press fitting 2 tiny spring pins, this is now held is with a single common screw (to the BOM) and a dab of loctite. This removes an item from the BOM and makes the assembly generally easier.

Ejection Port A - An angled relief cut was added to help the shell align and bolt move past it more easily. Entire port was widened in general.

Ejection Port B - The ejector slot was reconfigured to require less or no support to print.

Trigger - pin hole was tapered to help the pin retain better. Chamfers added to reduce support needed.

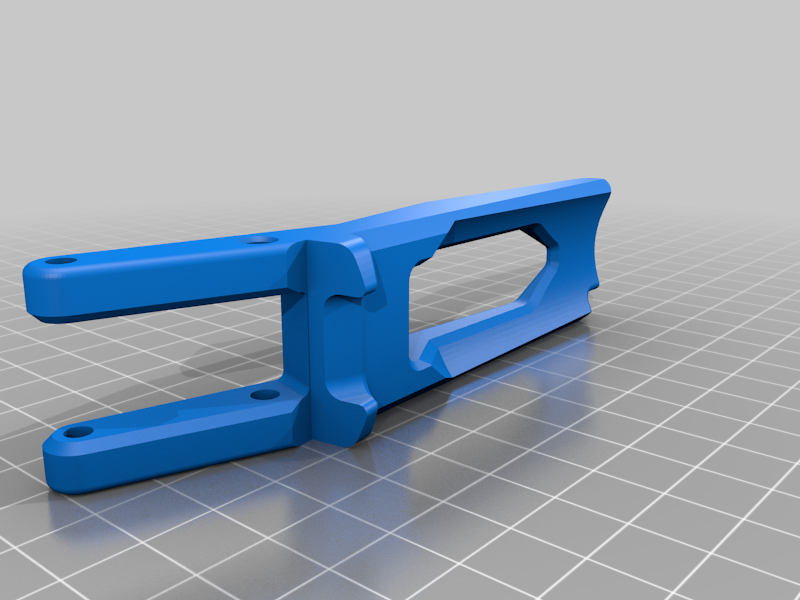

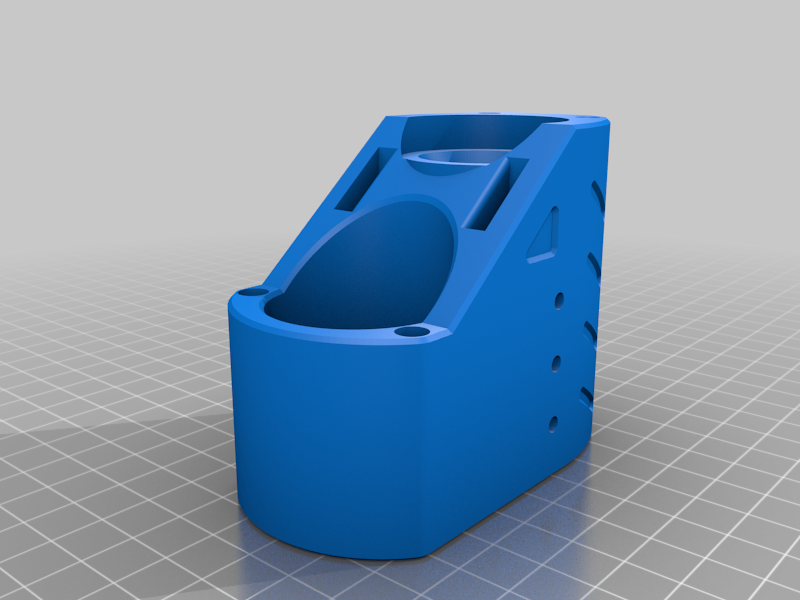

Pump Grip - A cavity for a captive nut was added to comply with the new action bars. These look better and are also stronger than previous designs. The angled grip slots also take the support out of the prints while approaching a more cosmetic appeal.

Handle Frame B - Priming indicator windows were added to both sides, so you can see if the blaster is primed by glancing from the side. An additional mounting hole (optional) was added to the bottom to allow more accessories and cosmetic options to be installed.

Handle Frame A - Reduced support needed for this part.

(2/6/2019) STEP files of the Dart slug was added so you can freely make your own variations of the ST shell.

All new shells can be found on the shell page provided in the links at the top of the description. Outdated were removed from this page except for the base Buckshot shell.

(1/27/2019) A big update is coming soon, including significant hardware changes to improve the ease of assembly. New assembly guide coming too.

For now, 2 new part files to fix some issues and add features.

Ejection_Port_A - Relief added to improve the feeding, as a vertical lip was removed because it was causing the shells to sometimes jam while feeding. Chamfers were also added to help combat elephant footing and to improve the general smoothness of the operation. Some dimensions were decreased to allow for even looser print tolerances while still allowing proper function.

Barrel_Coupler - One of the holes for adding picatinny rails is now complete and no longer just aesthetic. You can now attach a rail point here. Also same as above, chamfers were added to aid in the elephant foot issue.

(12/11/2018) Nothing huge, just added a barrel frame option with the entire "SPRING THUNDER" as a single piece for seamless embossed printing. It's here as

BarrelFrame_R10_V1BC. It's the BC unit. Also if you'd like to check out for more general news and updates, there's a facebook group for anyone to join. Shameless self promotional plug: https://www.facebook.com/groups/SpringThunder/

(11/21/2018) Lots of new updates, so new that I'm going to need to revise the assembly guide.

Bolt - Decreased ledge to improve ease of assembly of extractor and plunger tube. Plunger tube assembly is immensely easier now. You just twist it on instead of pressing it. This reduces assembly difficulty while also imposing less force on the sealing O-rings allowing for a cleaner fit.

Handles - widened cavity for the captive nuts for ease of assembly of the trigger guard. This was way too tight for no reason before.

Rear Spring Guide - Thickened backend to reduce depriming catching and removed the Shock Washer part from BOM. This is to be made with 3mm top/bottom solid infill.

Shock Washer - removed from assembly, one less part to print.

Ejection Port A - Widened front chambering slot to reduce interference with bolt assembly.

(11/11/2018) Shell officially release: https://www.thingiverse.com/thing:3210080

(10/8/2018) I know it seems like updates are suddenly rampant, but I'm trying to release more parts and support for the project now that the userbase is growing. Anyways, I made and released picatinny mounted Sling Points here: https://www.thingiverse.com/thing:3144712

Which by the way, because they're using the picatinny system, you can use this attachment on your airsoft guns or possibly even a real gun if you really felt like it.

Expect an assembly update later this week. I made a change that reduces the part count by 1 while saving assembly time.

(10/2/2018) Model 4 Files Officially released - Along with its own signature on the side of the blaster. Page for the shells coming soon. Added some updated pictures.

New Plunger head - redesigned for a tighter seal yet looser fit to give more power per shot at the cost of over 30 hours of redesign from me. This can be printed at 1.2mm walls with 1.5mm top/bottom fill and 20% infill.

(9/30/2018) Stocks Revised & Released - https://www.thingiverse.com/thing:3129063

(8/25/2018) Model 4 Released - Found inside the new file "Zip 4.1_Frame"

New model features better acce

/https://fbi.cults3d.com/uploaders/15531357/illustration-file/7d60a74b-8a87-445c-b884-5b4875f5e9a7/40485021_320375005384713_1928731368657780736_n.jpg)