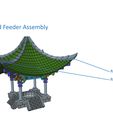

3D model description

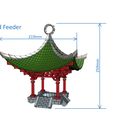

This meant as an Bird Feeder for little Birds like Sparrows and Coal tits that you can 3D print. But it became also an amazing Puzzle! With 41 different Parts, and many are printed more than once, it is a bit of an challenge to Assemble this Japanese Temple.

So if you like Puzzles, 3D printing and Model making, this is the Model for you! :-)

to see it in action: https://vimeo.com/829781543

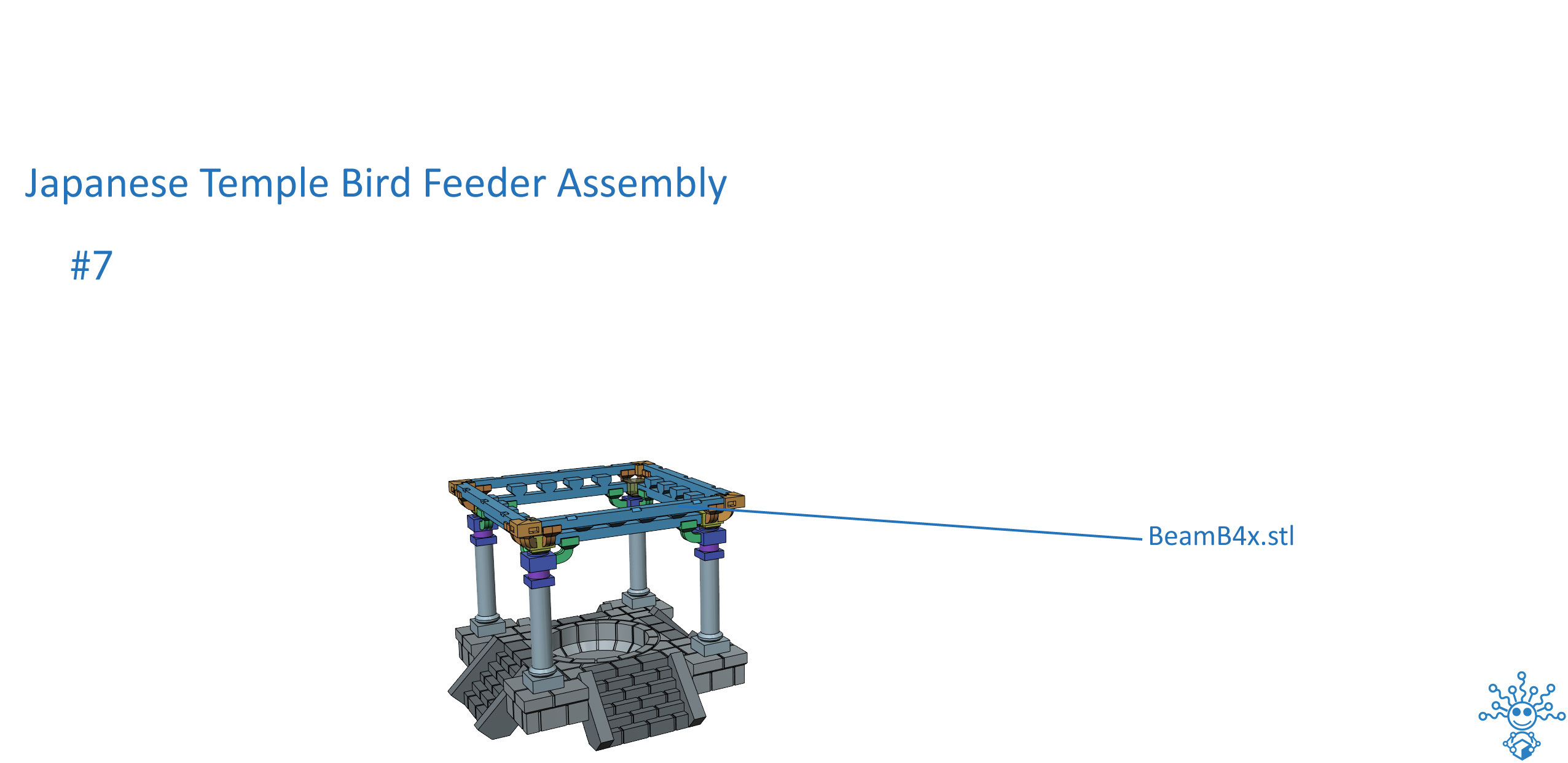

This Temple is inspired by Japanese Temples and I hope I did them any justice. These Temples look very simple from a distance, but when I zoomed in I realized that they are not. The Beam Constructions are amazing and impossible to 3D Print nice in one whole. Therefore this model started to be many peaces. These peaces all slot together as an puzzle, just as the real ones.

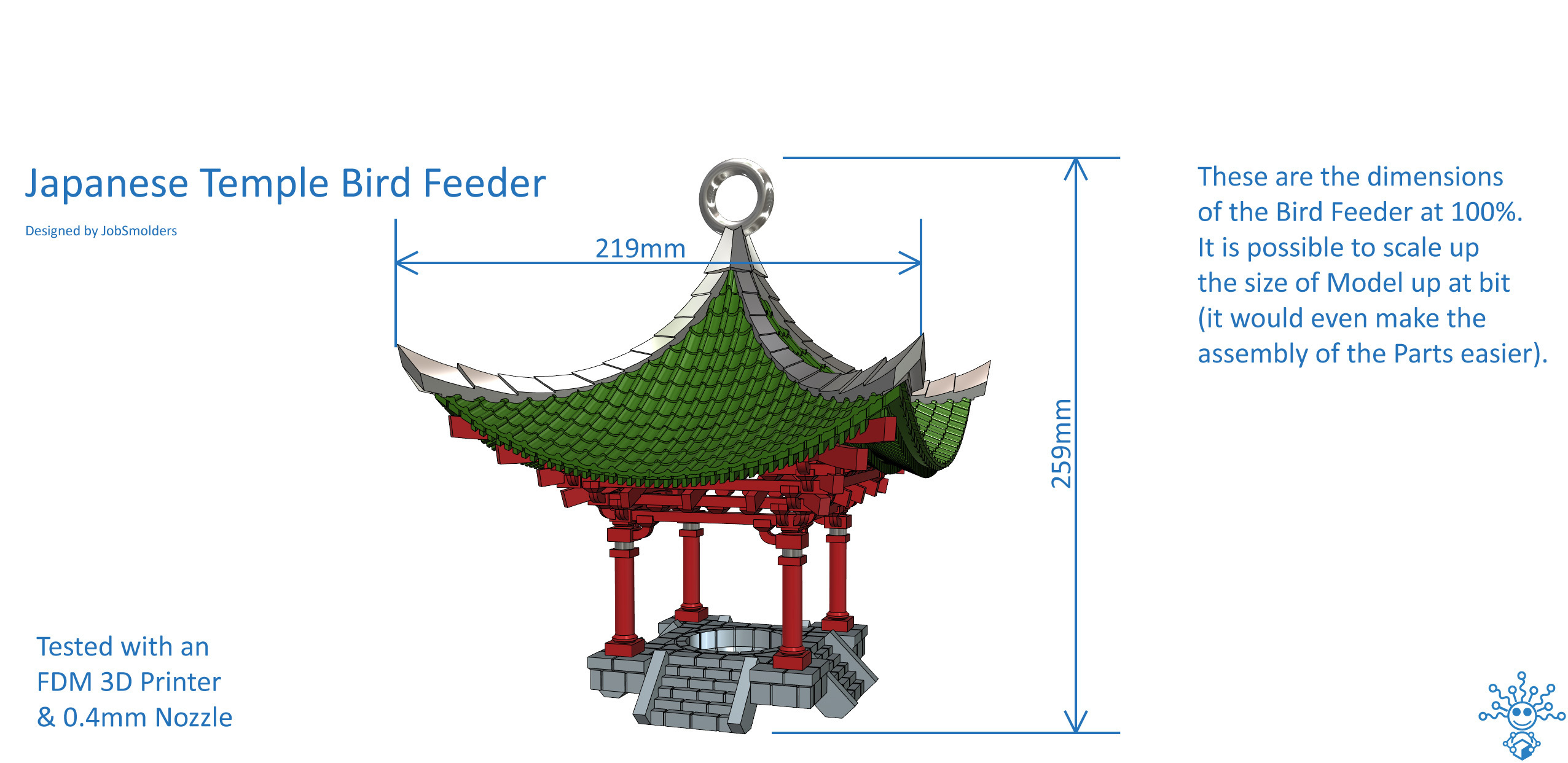

The Japanese Temple is only 259mm high and 219mm wide. It is very small, but fits on a standard sized 3D Printer.

Do you think it is to small? Than you can always print it bigger :-)

Assembly

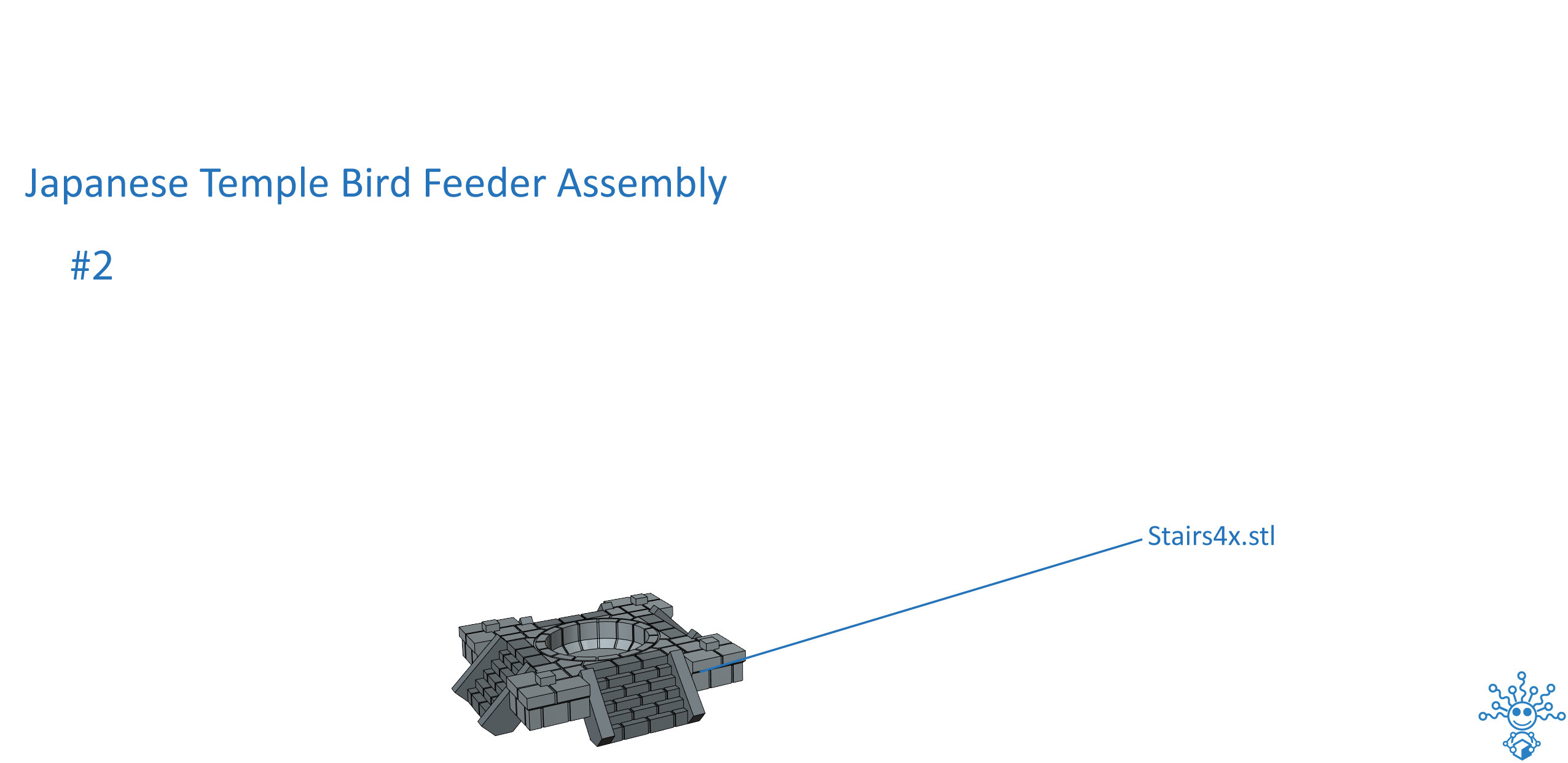

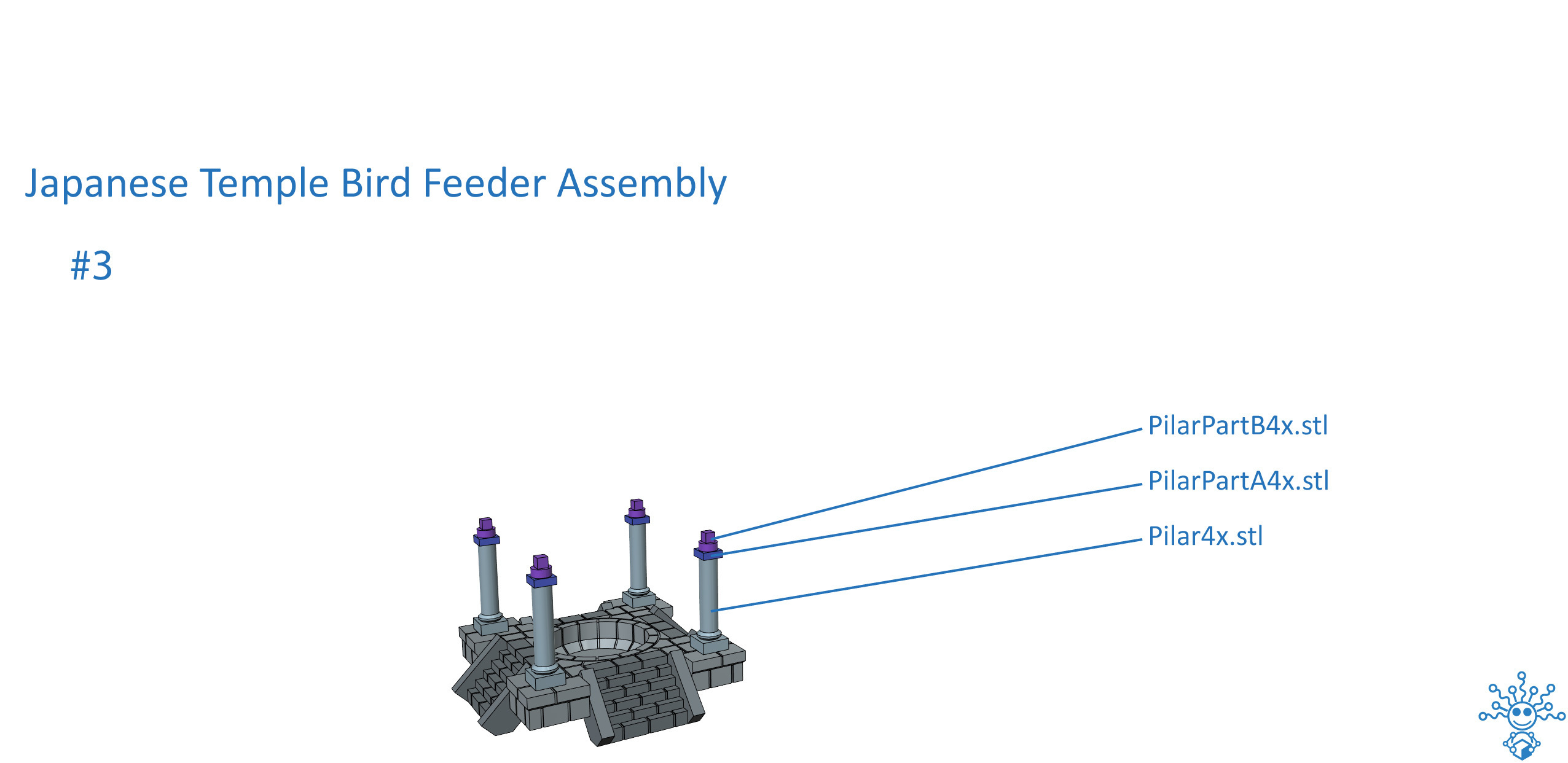

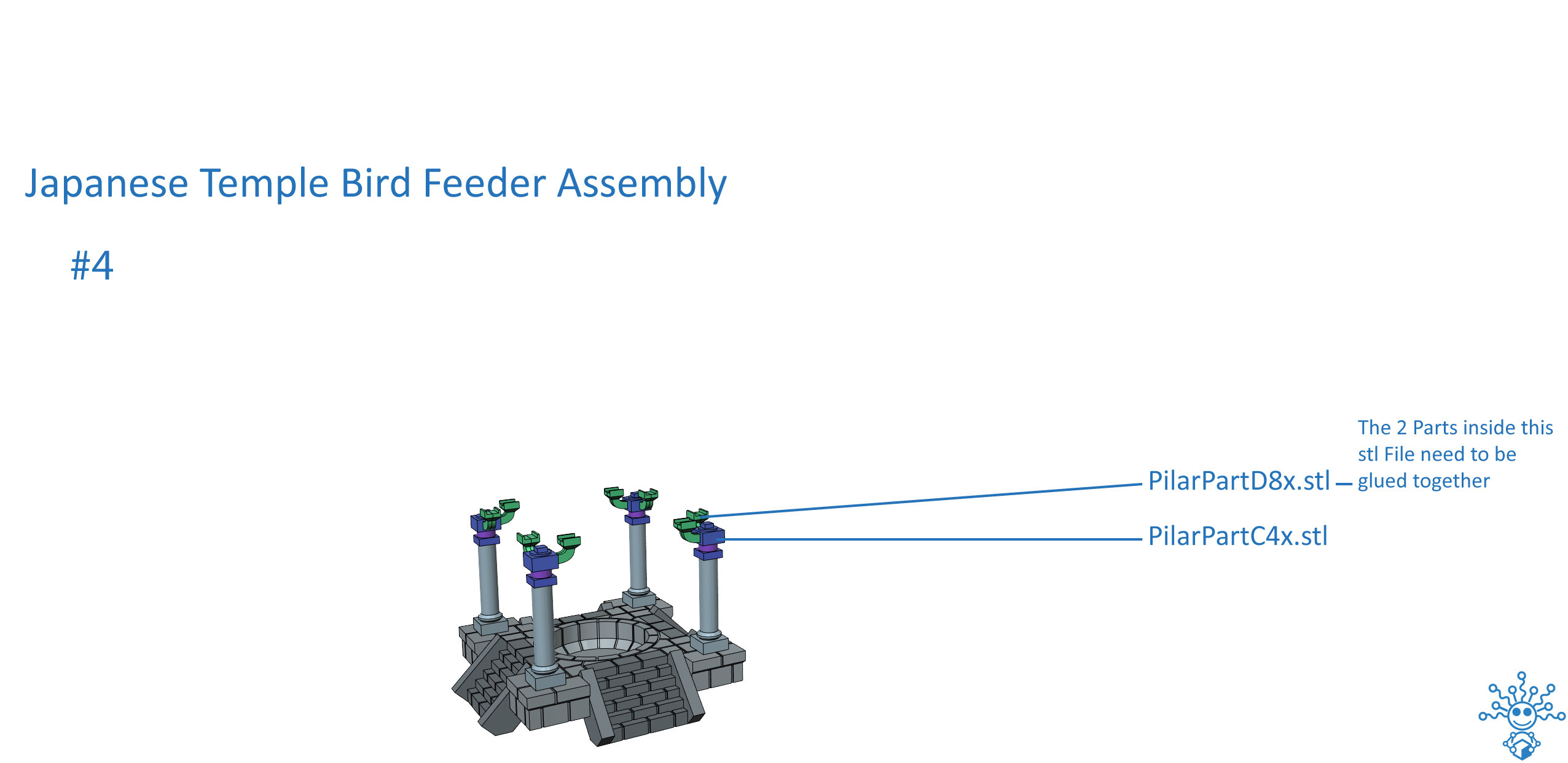

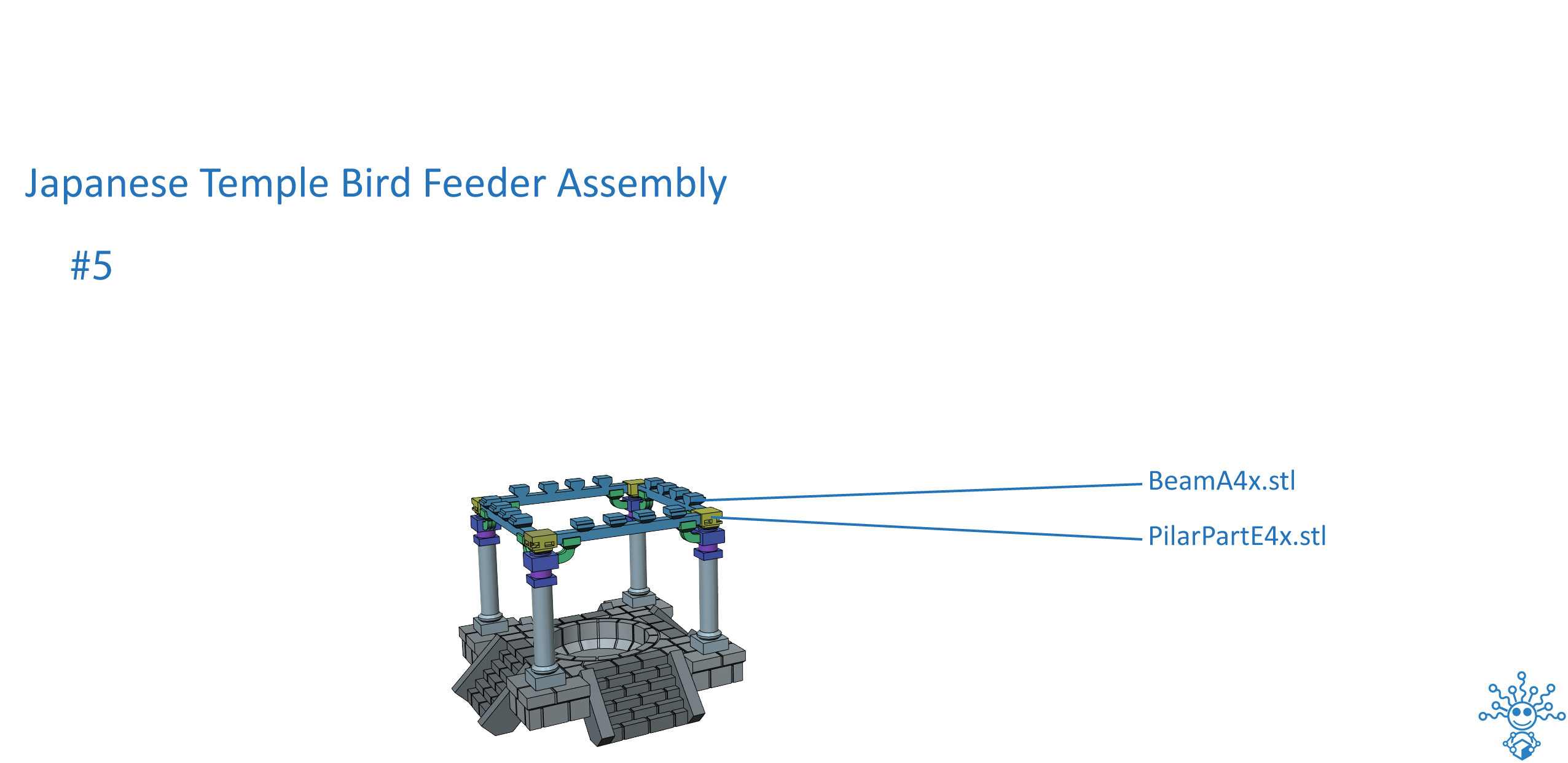

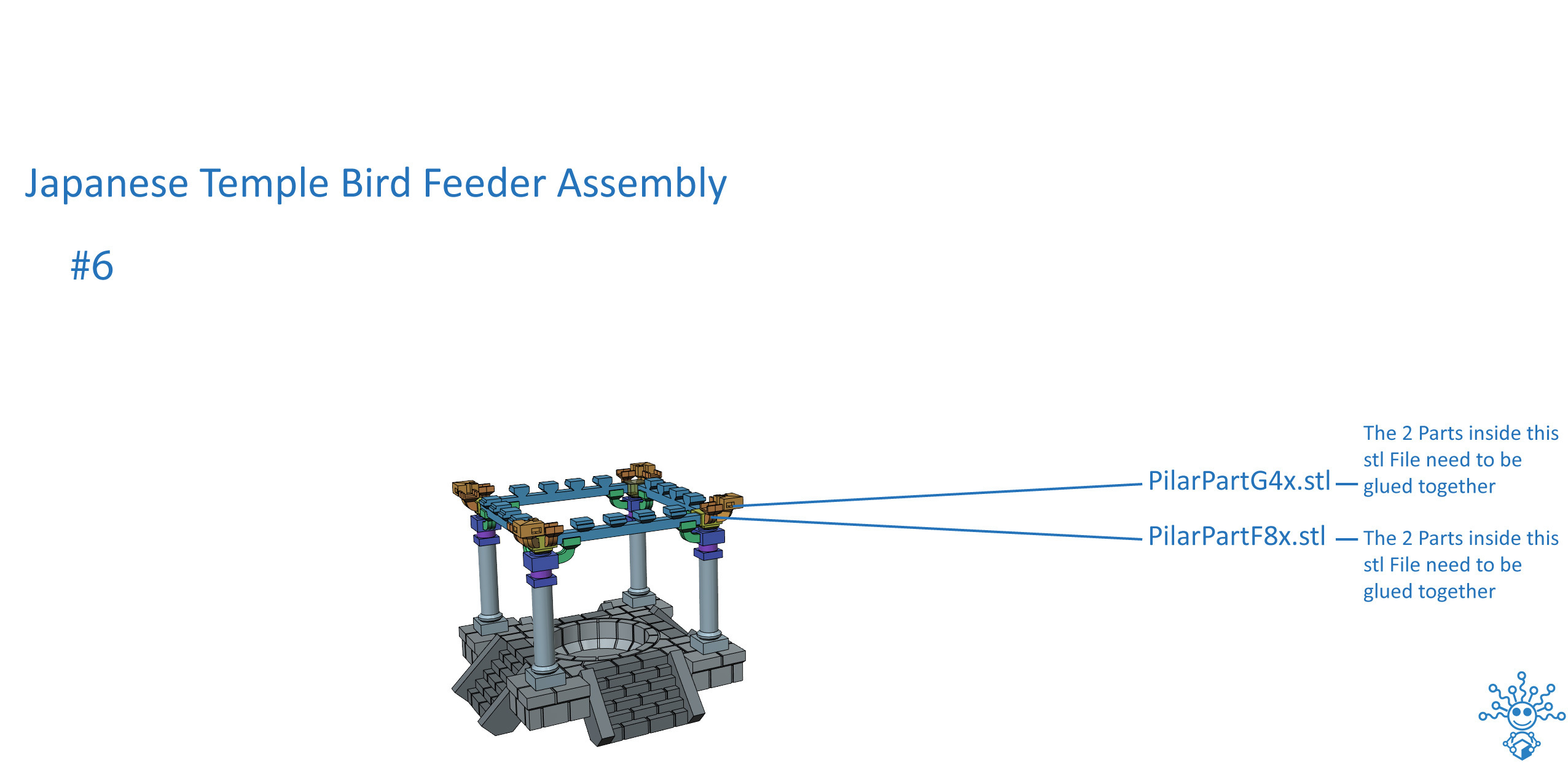

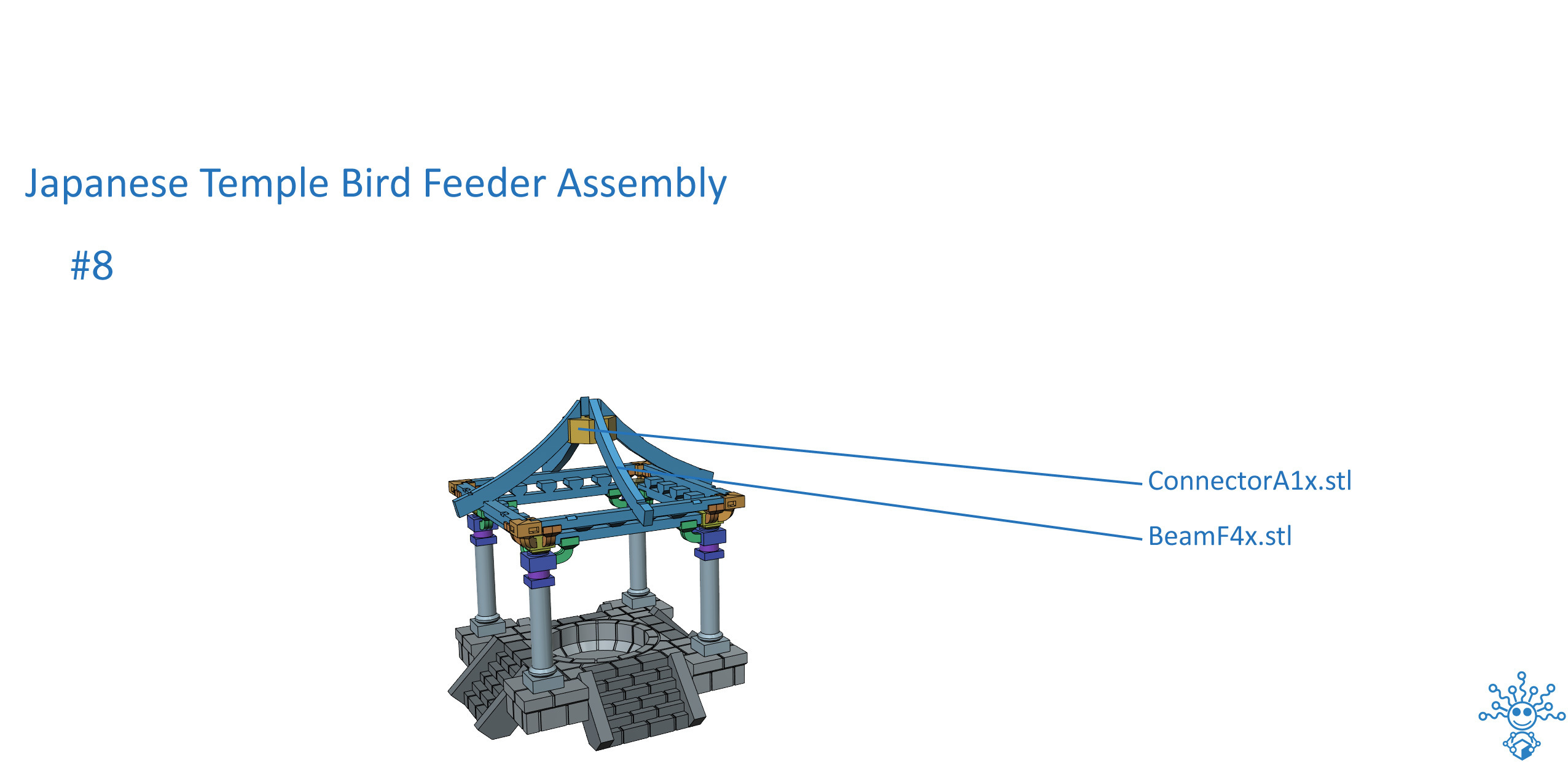

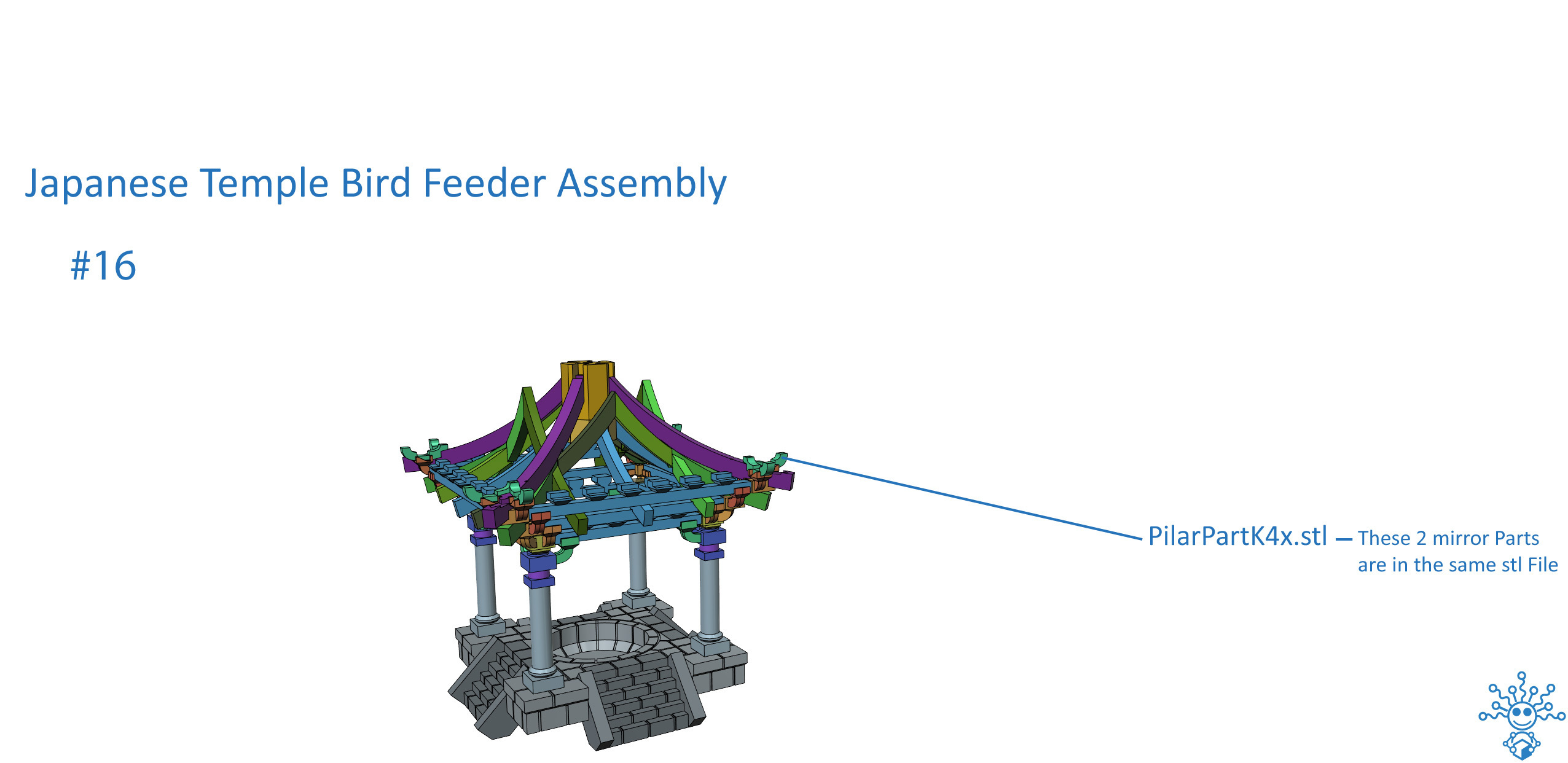

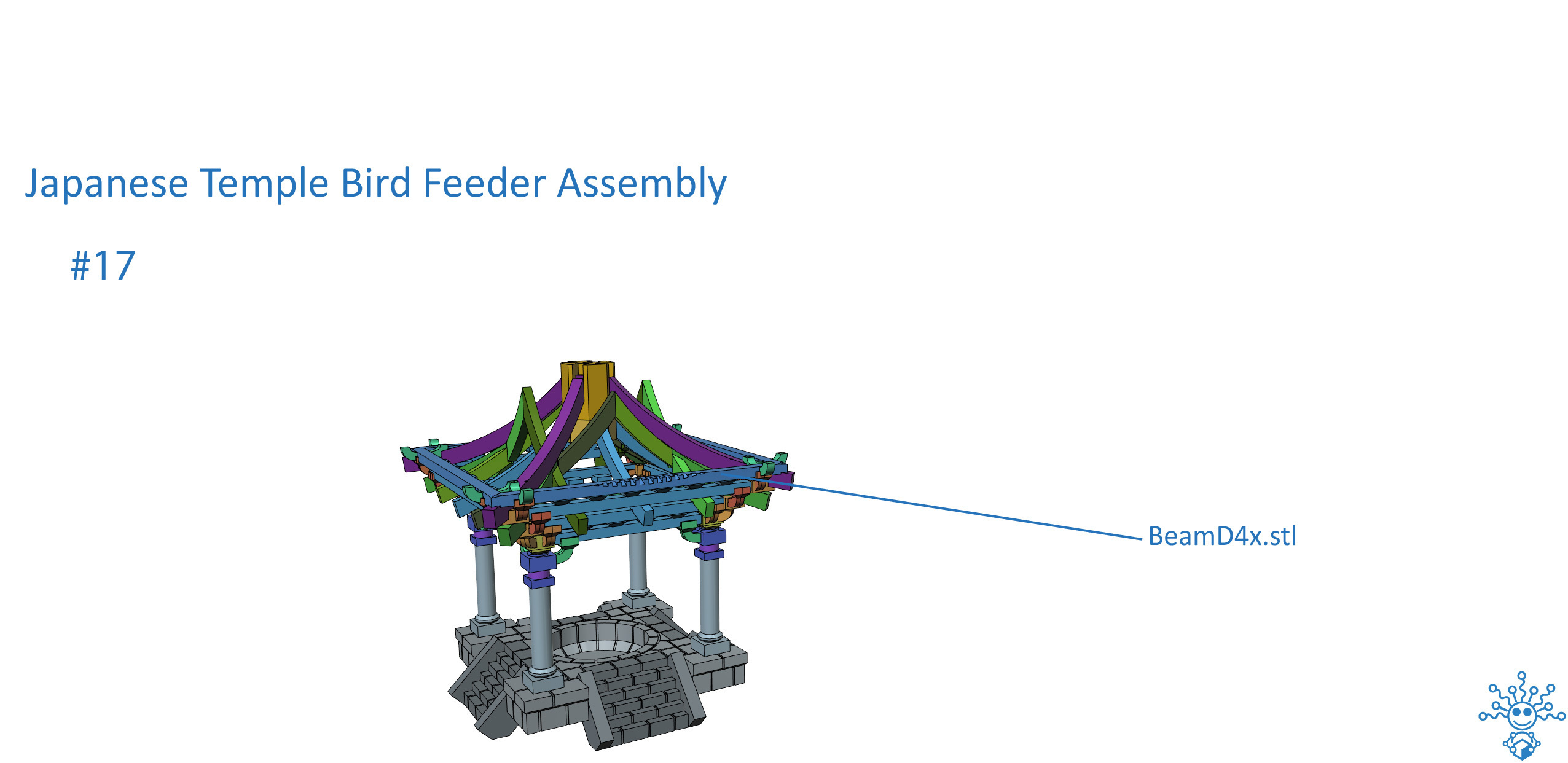

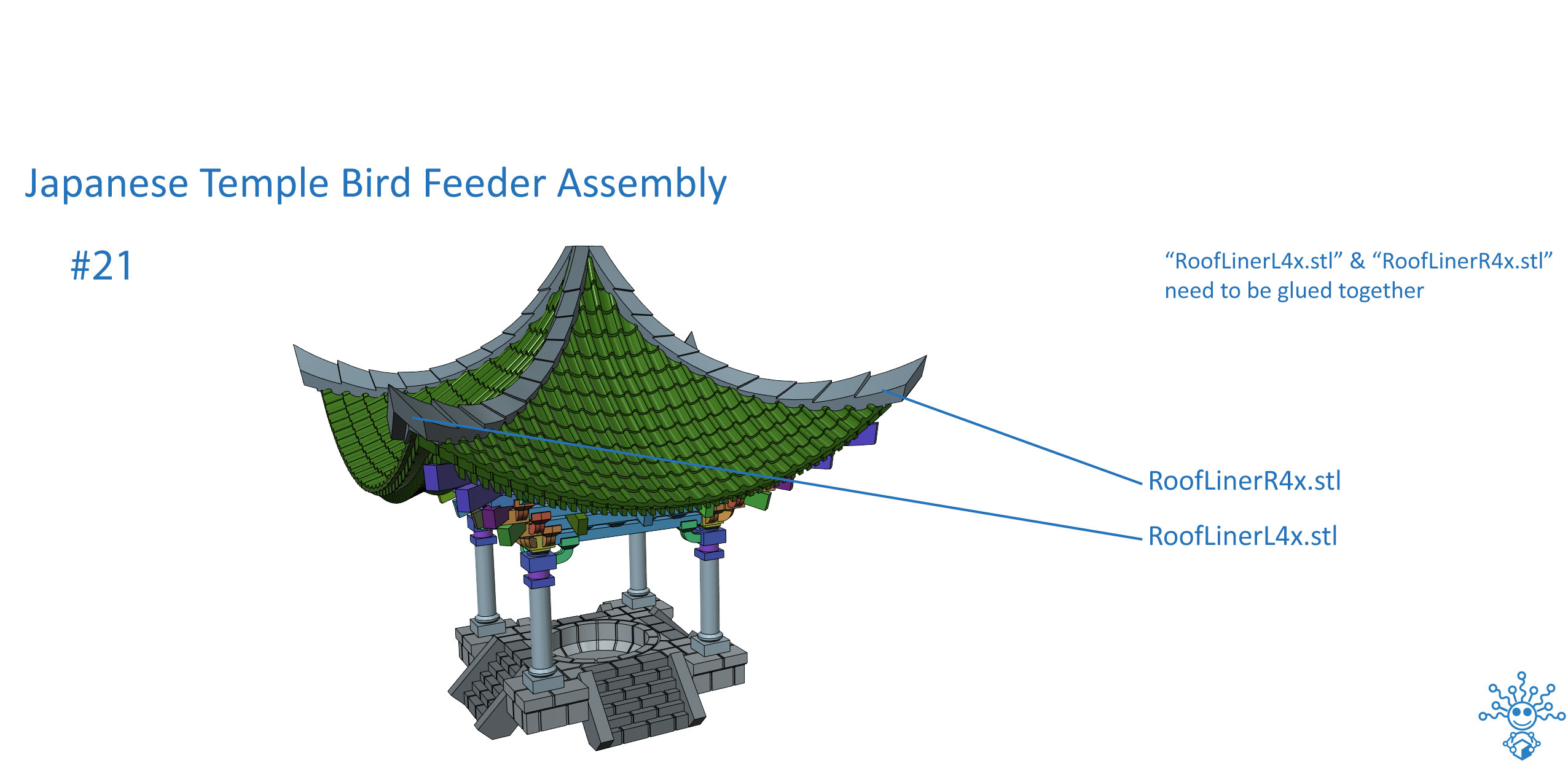

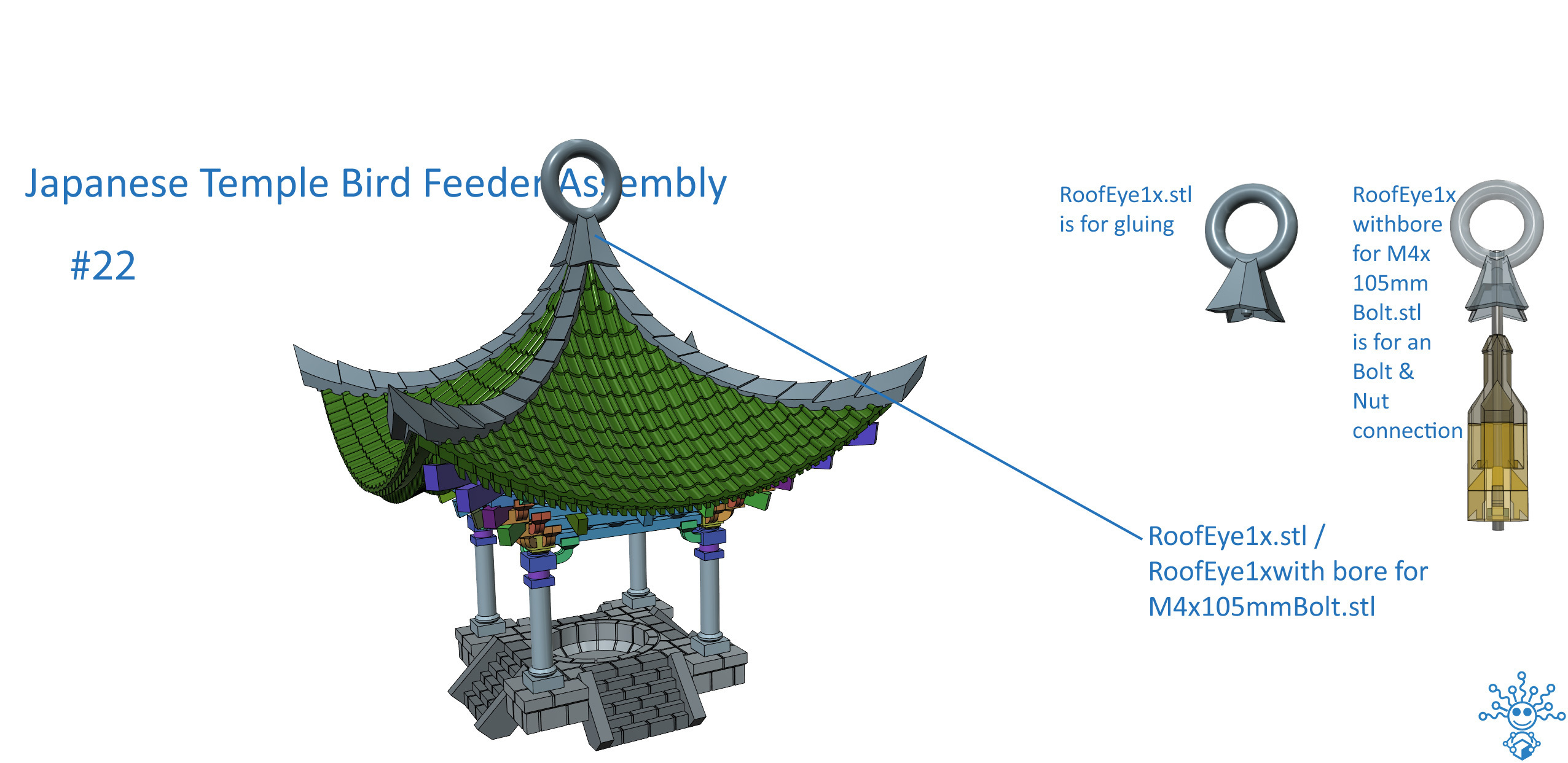

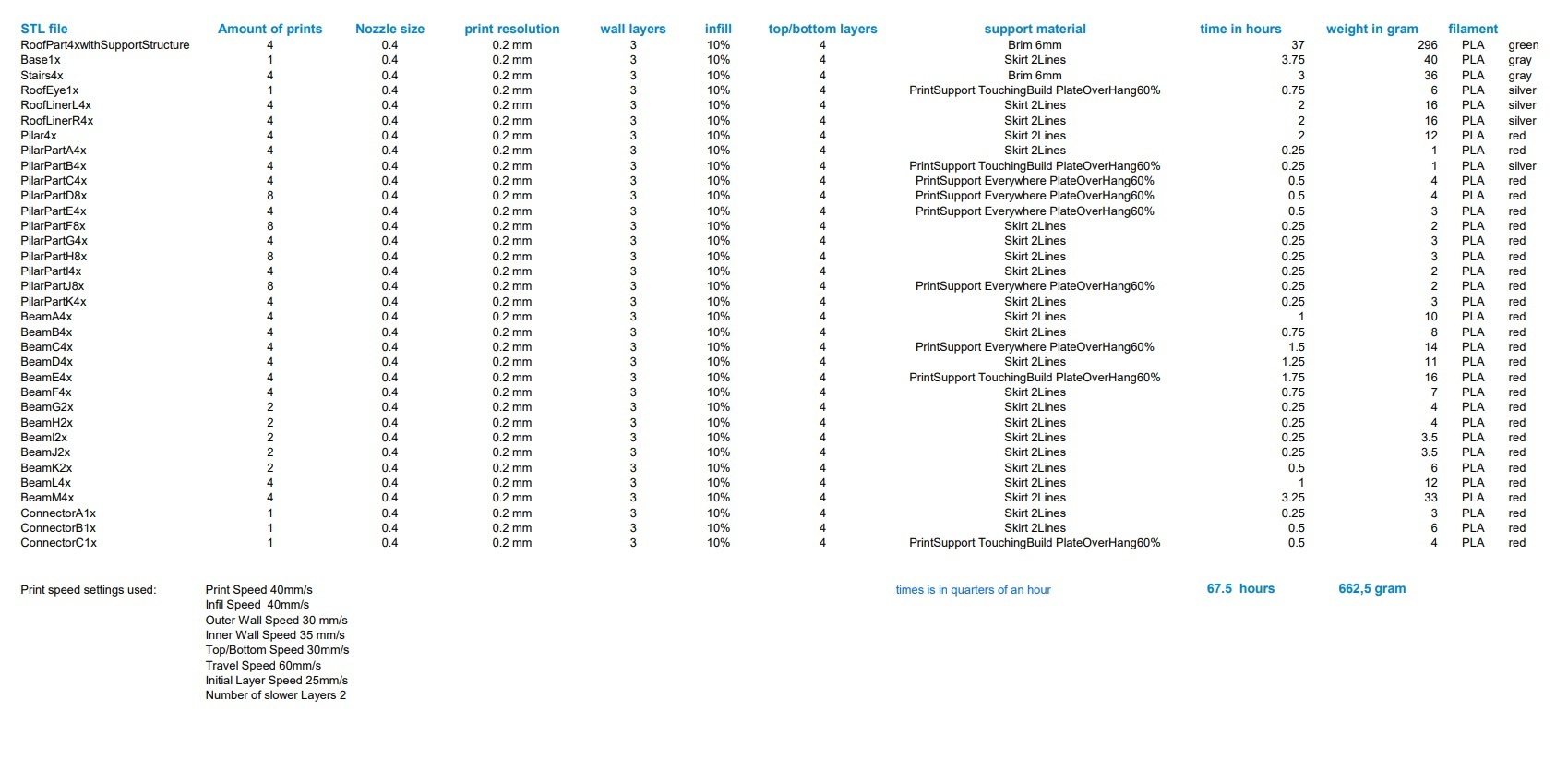

This model has 41 different parts, but only 34 stl Files, because sometimes I included the mirror part in the same file. Some Parts are need to be Printed more than once. Therefore I included the amount of Prints needed into the file name. The last 2 characters tel you how many times you need to print the Part. So if it ends with “4x” you know it must be printed 4 times :-). Additionally I have added an Image in the Photo Section with my test print data. In this list you can also see how many times you need a certain Part.

In the Photo Section I also added 22 images to show you how all the Parts go together.

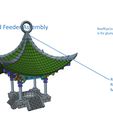

Note: in Image 2 you can see the Staircase already depicted. In real Live, it is better to glue then on as last (of course :-).

Then I also included the Files “Total Assembly”. These Files are not for printing, but for you to see the Temple assembled in 3d. I hope this makes assembly easier.

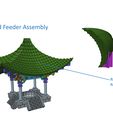

The Eye on top can be glued on or mounted with a threated M4 Rod or Bolt. The length of the Bold should be at least 105mm long. That's not very common so I just glued the Eye. If you decide to scale this model up, it might be wise to use the Bolt option. Please See Image 22 in the Photo Section for more info. The Roof Liners (RoofLinerL4x.stl and RoofLinerR4x.stl) are printed in 2 sections and then glued together. I am not fully sure thats the best way so... I also created an optional file ( OPTIONAL RoofLinerLandR4x.stl) with these two parts already together. Did you almost finished assembling the Model but the Eye on top does not fit? Just scale up the Eye (RoofEye1x.stl) to 105% size.

I also painted some parts white, to be more true to the real thing. To keep all the Parts together, I used standard Super Glue.

I think I have told everything you need to know.

But if you still have questions, feel free to ask :-)

3D printing settings

This Model is tested with an FDM 3D Printer and 0.4mm Nozzle. In the Photo Section I added a list with my printing data. All the settings in Cura (Slicer Program) are mentioned. With my settings I took me approximately 67.5 hours to Print and I used Approximately 662.5 Grams of PLA 1.75mm Filament. The tolerances are 0.1 – 0.15mm so you must have a good working printer. Printing this model bigger than 100% makes you live a lot easier, because the tolerances will be bigger, when scaling up.

Note: The Roof Parts (RoofPart4xwithSupportStructure.stl) are printed in the upside down position for a better result. To prevent it from tipping during the print, it has its own support material build in. This support material must be removed when printing is done. Please see Image 20 for more info.

Do you want to create you own support material? Then use the file “RoofPart4x.stl” instead.

/https://fbi.cults3d.com/uploaders/13250808/illustration-file/8ca0b733-d637-4b92-bc99-575fa1615419/1.jpg)