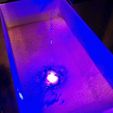

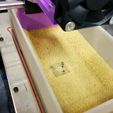

In the last couple days, I have experimented how to transform Rigidbot FDM 3D-printer (and others too) + $200 L-Cheapo v2 laser cutter/engraver module to crude SLS (Selective Laser Sintering) printer for powdered build materials.

With this setup my goal is to have with minimum modifications:

- Standard FDM-type 3D-printer

- Laser cutter / engraver

- SLS-printer

Currently the setup is not very fast and it takes about 10 minutes to make one layer, but hopefully process can & will be optimized with better slicer & gcode settings.

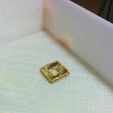

I have experimented mainly with cane sugar, because I had it and scrap prints are delicious. Aroma of burning sugar is also much nicer than burning plastics. If you plan to use some other material, like powdered ABS, you will want to adjust your printing speed and other settings accordingly.

The plow setup is very simple, but also a little too violent, so you will need to adjust the printing starting height so that the first layer of material bonds to build box bottom for support. If the print does not stick, lower the print starting height.

I also recommend to check your laser lens assembly and tighten the spring inside it.

WARNING: This is highly experimental and if you do not know what you are doing and won't choose to wear approratiave protection, you will go blind and burn your house down, so don't do it.

But if you do it, do not ever leave your printer unattended or look at the laser light without suitable protection gear. Even with protection goggles it is unwise to look at the beam and it is unfortunate for our eyes that the only way to focus L-Cheapo properly is to stare at the laser focus point and adjust the lens assembly. B)

You'll need:

Fine cane sugar. More darker the sugar, less build time. Cannot be sticky sort, even the lumps. Cane dust sugar might give better results but it is harder to spread evenly.

The plow (aura.stl) is actually the only Rigidbot 3D printer spesific part, so if some other printer is used you need to remodel it to fit your own extruder assembly. I printed it with PLA and 0,15mm layer height.

L-Cheapo v2 laser module (if your laser begins to flicker, put an larger cap to the output). I used this marvelous design by xzivr: http://www.thingiverse.com/thing:593054

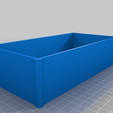

Build box (loota.stl) printed with PLA, I used mild under extrusion at the build box floor, so that there is more of an adhesive surface to sugar stick to.

The code assumes that you drive your Z-axis to 80mm and also move your Z-axis limit switch so that it does not crash with the build plate / box.

If you have Simplify3D, you can just import all my setting from the provided laser80.fff or you can adjust my G-Code for your setup parameters.

Extrusion width: 0,05mm

Layer height: 0,1mm (this depends what material you are using)

Top solid layers: 0

Bottom solid layers:

Outline/perimeter: 1 shell

Fill patterm: concentric (seems to work better than rectilinear

Infill: 10%

OBS! Simplify3D and the G-Code both assume that you drive your printer manually at 80mm before executing.

Layer change G-Code (remove the comments before using):

M400 ; Wait for previous command to finish

M104 S0 ; Laser OFF

G92 Z80 ; Set Z-level to 80mm

G0 Y190 X47.5 F3000 ; Go to the back and center of the build box

G91 ; Set relative movement on

G0 Z-75 F3000 ; Move Z to 5mm @ 3000mm/m

G90 ; Set absolute movement on

G0 Y40 F1000 ; Drive to 40mm from the front of the build box

G91 ; Set relative movements on

G0 Z30 Y-30 F1000 ; Move Z to 35mm and 10mm foward to the front of the build box

G0 Z-33.9 ; F1000 ; Lower the Z-axis height to 1,1mm sweeping height (this parameter shoulg be adjusted to suit your build material)

G90 ; Absolute movement on

G0 Y160 F1000 ; Sweep back to 30mm from the back of the build box

G0 Z+80 ; Rise Z to 80mm

G92 Z0 ; Set Z to 0

M400 ; Wait for previous commands to be executed

M104 S100 ; Laser ON

You need also this start.gcode, these are slightly modified from the original from robotseverywhere:

M104 S0 ; Laser OFF

G21

G28 X0 Y0 ; Do not check the Z-level to prevent crash to build box

G92 Z80 ; Set Z level to 80mm, which has to be set manually before print

G1 Z+80 ; Drive to Z to 80mm, actually it is already there!

G90

G92 X0 Y0 Z0 E0 ; Set current position to ZEROES

M400 ; Wait

M104 S100 ; Laser ON

And end.gcode

G91 ; Set relative movements on, why?

M400 ; Wait

M104 S0 ; Laser OFF

G28 X0 Y0 ; Park

M84

/https://fbi.cults3d.com/uploaders/21153246/illustration-file/e9eabf7e-2591-44b3-bc8b-20e49907fb01/IMG_20150326_030922.jpg)