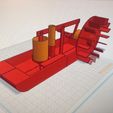

This model is going to be a working "steam" powered Riverboat. Twin Paddle Wheels. A rocking beam steam engine. I am designing this model in Tinkercad. I am a total neophyte when it comes to 3d design, up to this point my best design has been a knob for a radio scanner.

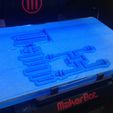

Update 7/2/15 : The First rev of the complete engine is now posted. All the parts are there but they haven't been tested yet.

Goal: To create a 3d printed working "steam" engine that will power a boat using paddle wheels. The boat will need to be buoyant enough to support itself, the engine, the paddle wheels and the "boiler".

The "Boiler" will actually be a reactor, Using hot water, to convert Dry ice to C02 gas, the C02 gas will take the place of steam in this engine.

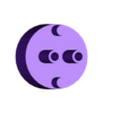

Concerns: A steam engine is usually made to tight tolerances. parts are machined out of metal. I have to print using low resolution simply because I would not have time to print at high res. This means my engine has extra room around the pistons and fittings. Will the tolerances be close enough that the engine functions?

It will be interesting to see if the "boiler" can simply move the piston.

since I have never designed a steam engine before and I am simply creating the parts using Tinkercad, I'm not sure about the exact measurements for parts such as the crank arm, to accommodate for this I am designing certain parts to be adjustable and once the correct size has been determined, these parts will be "frozen" in size with glue.

Update 7/8/15. The "boiler" can definitely move the piston!

https://youtu.be/PmPnefZgURk

Activating the "boiler"

http://youtu.be/AbHvNOdBUkY

Boiler running on Hi!

http://youtu.be/Kt9tBcXdJtY

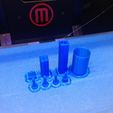

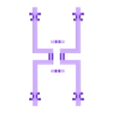

Ran into a mechanical issue. I didn't take into account the thickness of the Cylinder lid, so that shortens the actual distance the piston can travel. this would in turn shorten the distance the crank throws. so to adjust for this I have simply printed 3 different size cranks and made them adjustable so that I can take into account the error.

I can already see there is huge room for improvements. I invite everybody who is interested to work on this. All files will be posted on Tinkercad so that they can be modified at will. I will start a list of modifications I plan to try after the initial design is finished.

Update 7/14/15 As I feared I am running out of time to get all the parts printed, -with the limited time available to me on the library printer, I probably wont be able to get the the hull much less the paddle wheels. - However that I won't finish in time to meet the deadline wont stop me from finishing the project, This has been a fantastic learning experience.

At this point the main linkages are done. piston > crankshaft, and then in this video I show that the piston works when the cylinder is mounted to the valve manifold. - simply blocking the manifold with my finger backs up the pressure to move the piston.

Next step is to create the instructions and make sure all the current pieces are up to date.

Next pieces to print are the piston for the valve and the valve cam wheel. that should be all the pieces to make the engine functional. I will try very hard to get the hull done too.

https://www.youtube.com/watch?v=_qziQgTGsbk

7-14-15 update2 replaced all the files with updated versions (single files to make printing easier)

Future Modifications:

a new design for the reactor/boiler. I am using a small soda bottle, my safety valve is a rubber band holding the lid on. The narrow neck of the bottle means it is difficult to load the boiler with dry ice. a better design would have a larger opening to accommodate bigger pieces of dry ice and it would have a better designed safety valve and a better way of introducing warm water into the boiler.

a simple improvement would be to make the piston powered in both directions, up and down, this would double the power with just a little modification.

a better design for the manifold valve, perhaps a rotary valve instead of a piston.

/https://fbi.cults3d.com/uploaders/16070620/illustration-file/2ee19e42-3518-4c5f-a55b-a490edde1502/IMG_0551.JPG)