---- WORK IN PROGRESS, NOT GOOD ENOUGH YET FOR FULL RELEASE! ---

Version 1

This is the first version of a mold to create silicone tires for Daniel Norée's great F1 car (https://www.thingiverse.com/thing:1193309)�. A printed low profile rim by Palmiga is required (https://www.thingiverse.com/thing:1103751).

Here's how to use it:

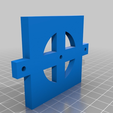

1.) Print all the parts, a low profile rim and a wheel lock from the original F1 STLs.

2.) Cut two 6cm pieces of M3 threaded rod and a smaller one to mount the wheel.

3.) Close the holes in the rim with something, for example a blob of hot glue.

4.) Mount the rim to the base and assemble the casing.

5.) Mix your silicone and carefully fill in the gap between the rim and the mold wall.

6.) Attach the top tightly and fill silicone in the holes on top.

7.) let it cure

8.) remove

9.) use a sharp knife to trim

10.) enjoy :-)

So far I have only created one tyre. I think it came out reasonably well. Removal was a bit of a challenge but it worked. The grip is much better than printed TPU tyres. I'm not entirely sure yet if the tyre sits strong enough on the rim creating it with the actual rim as center. I might have to use a center with a slightly smaller diameter to get a better friction fit. I'll update the design if this was required. Also I might change the design to ease removal a bit. My intention is to use Oogoo (https://www.instructables.com/id/How-To-Make-Your-Own-Sugru-Substitute/) however my first try at this didn't work (wrong silicone) so I tried the mold making silicone I had at hand first.

Thanks to Daniel for creating and sharing with us this great car, Thomas Palm for the nice low profile rims and to Rocketboy for the inspiration to use a mold and silicone (https://www.thingiverse.com/thing:451146).

##Version 2

I tried to use version 1 with Oogoo but that doesn't work at all. I even tried the recipe for pourable Oogoo but besides it probably being even more unhealthy, that also didn't work well. I had serious shrinkage and the material stays much softer.

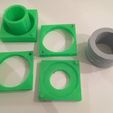

So I tried a different approach for the mold and I'm slowly getting there. Version 2 is slightly too large therefore it's not uploaded but I actually managed to more or less properly fill the mold with Oogoo. See the gray tyre picture. It still has some air pockets though. I chose a smaller inner diameter therefore the fit is much tighter. However due to the consistency of the Oogoo it's nearly impossible to fill the mold completely even when pushing the stuff in.

After making the form smaller, I'll try a ring to help push the Oogoo down. If that doesn't work either, I'm thinking about creating the base with a center tower (like the rim in version 1) and a few outer parts plus top. One can then iteratively fill a smaller height each time hopefully making it easier to actually get the stuff everywhere.

The consistency of the cured Oogoo seems really great. Good grip and relatively strong. It's still not field tested on the car though.

##Version 3

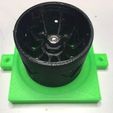

Version 3 is now online. Tires come out reasonably well with Oogoo. Also there's now a push ring to aid getting the Oogoo in there. They do have serious grip and the car drives much better than with printed tyres. However there's still a problem. The tyres don't stick well enough to the rims and eventually come loose. So back to the drawing board. I'm thinking about reducing the inner diameter even further to strengthen the friction fit. Alternatively I might create my own rims with a bit of a guide for the silicone tyres on the sides. Some glue or sticky tape might also be an option. Simple double sided tape however is not sufficient. I tried that already.

If anyone has an idea what kind of glue might work, please leave a comment.

##Version 4

Getting there! Version 4 is now online. It's intended to be used with special rims designed by Thomas Palm which provide a structure inside of the silicone. The special rims can be found here: https://www.thingiverse.com/thing:2625567

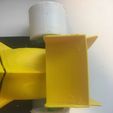

The version 4 mould is based on the 2017 F1 design and intended to be used for the larger rear tyres (for now). And since it's based on my version 1 mould design and the silicone is required to flow around the support structure, it likely only works with 2 component silicone with a suitably high viscosity. I only managed a very quick test outside due to time constraints and lots of rain but the results seem promising. Grip is certainly much higher than with printed tyres and the tyres don't come off. I don't know yet how durable they are so try at your own risk. See picture with white tyres on yellow/black F1 to get an idea what it looks like.

Once I have time and it's not raining, I'll do a longer test and if the test is successful, I'll address the front wheels.

/https://fbi.cults3d.com/uploaders/26710753/illustration-file/59690705-8ff0-44f6-8806-e08209b104cc/49cdbc16e74a5c4159d05ea02859f79e.png)