Description

This is a nosanding bearing oldham coupler for Tevo tarantula printer.

It is designed to be small and simple to print.

For updates see at the bottom.

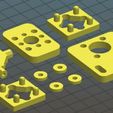

Printed parts list

1 x Top

1 x Bottom

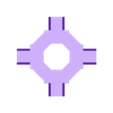

1 x Bearing cross

2 x Guide

4 x Washer

Use the corresponding STL's for your bearings (626 or 608). Guides are the same.

Non printed parts list

X gantry mount: 2 x M4 screws + 2 x M4 T-nuts (same as stock)

Bearing screws: 4 x M3 x 12÷14 mm screws

Bearings: 4 x 626RS or 4 x 608RS bearings. RS is for protection from dust. You could use ZZ or just plain unsealed bearings but those will collect dust with time.

Tools: 3 mm tap, 3,5 mm and 4 mm drill bits.

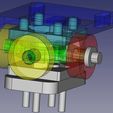

Functional description

This oldham was designed by me after seeing Vascojdb's design and seeing the advantages of bearings and no-sanding approach in an oldham. So the same goals:

1) Use bearings instead of plastic-on-plastic

2) Use the polished side of plastic that faces the glass bed, instead of sanding it

3) Almost no need to sand anything

4) Print all at once, no supports.

5) Minimum number of different parts.

After a question "why don't use common spinner bearings (608)" I made a modified design to fit those.

Printing tips

Print with low speed. Place the two guides at opposite sides of the build plate to give time for the plastic of the pins to cool.

Use the drill bits to enlarge holes to proper dimensions. If the holes for the guide pins are too large (their actual dimensions are 4.4mm and the pins are 4mm) after measuring the actual dimensions you coud addjust the corresponding constraints in the FreeCAD files, export the new STL's and reprint. In the FreeCad files the constraints that need to be changed are Bottom.Pad001.Sketch001.Constraint50 and Top.Pad.Sketch.Constraint30 which are the radii of the holes and are now 2.2mm.

Use the tap for the bearing screw holes to not cause a stress in small bearing guides.

Installation and usage tips

1) Install bearings on the BEARING CROSS.

2) Mark a pair of bearings (back/left; front/left;...) to check the guide size to the corresponding pair.

3) Check if the guides can slide almost free between their corresponding bearing pair. They should face the bearings with the shorter sides. Sand the shorter sides against a flat surface if there is not enough clearance. Try to keep the sanded sides parallel.

4) Pay attention when mounting the guides to the top and bottom pieces. They should be mounted on the bottom printing surface - the smooth one. Also those pins fit very tight and if you need to disassemble them for some reason (additional sanding, replacement,...) it is best to not pry them but tap through the holes.

5) Fit the top piece to the X gantry in such a way that when the Zrod is free it will be in the centre of the hole in the TOP piece.

6) insert the Zrod into the bearing cross paying attention to the orientation marked in step 2.

7) Screw the brass nut to the bottom piece and screw it on to the Zrod.

8) Pay attention to orient the bottom piece in such a way that back/front bearings step on it and top piece steps on left/right bearings

Others

Designed in: FreeCAD

Attached files: STL and FCStd (FCStd files could be found here: https://www.thingiverse.com/thing:2581521/files )

Material: used PETG but PLA should be strong enough if not in a heated enclosure

Take note that I did not actually print and test the 608 design. Just redimensioned the parts to fit those. There should not be any problems since the other makes are all with 608 bearings but if You encounter any please let me know and I will make the necessary adjustments.

Please post your makes and if you have any comments/suggestions/... feel free to post a comment :)

And while you are at it check the Belt tensioner/idlers mount

2018.04.19

Added newer versions of FreeCAD files (v2). The bearing axes of the bearing cross are defined a little different and this gives the ability to make its thickness a proper number (5,6 and 6mm respectively)

/https://fbi.cults3d.com/uploaders/26734769/illustration-file/76e6725b-0fbf-47d7-9ba5-ff9040bca150/Mounted.jpg)