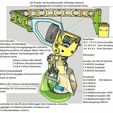

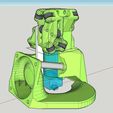

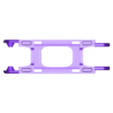

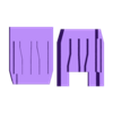

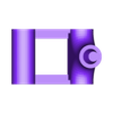

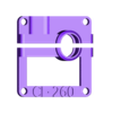

3D printer with cross kinematics, (Ultimaker system)

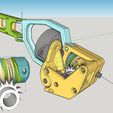

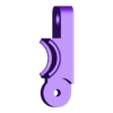

with ball-bearing print head on carbon shafts 8mm,

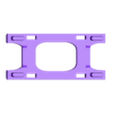

Direct extruder: 120 grams

with Bondtech double gears for 8mm shaft

0.9deg Round Nema 14 stepper motor 5Ncm 0.5A

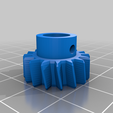

2-track globoid worm gear 1X8

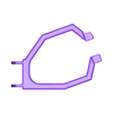

Swiveling with cable chain

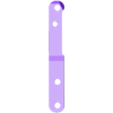

Filament guide with ball-bearing pulleys,

Ball bearing:

ØA X ØI X width

20 X 7 X 3 X 2.5mm Print head and pulleys

2 X 10 X 6 X 3mm swivel print head

4 X 8 X 4 X 3mm gear and extruder

Screws:

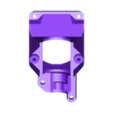

Exruder with E3D V6 hotend:

3 X M3X35 countersunk head

1 X M3X16 countersunk head

1 X M3X25 hexagon head

Miniature shaft coupling (reduction) 5X4mm

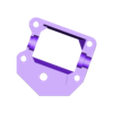

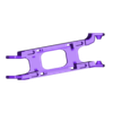

Print head:

10 X M3X10

10 X M3X12

10 X M3X16

4 X M3X25

12 X grub screws 3X10

2 X grub screws 3X6

4 X grub screws 3X4

20 X M3 nuts

There are 2 adjusting screws per axis on the print head to adjust the

clearance between bearings and shafts.

Screw in the adjusting screws just until the bearings are still running smoothly

Carbon or metal axles:

2 X Ø 8mm length suitable for the printer (for cross kinematics)

2 X Ø 4 X 45mm (for the gearbox)

1 tube Ø 6 X 20mm (extruder hotend connection via ball bearing)

1 X M6 snap ring (protection against slipping out)

2 Passive heat sink for motor

2 X silent fan 40mm (for hotend and component cooler)

3M thread cutter (cut 3mm threads in the Ø 2.6mm holes,

Mount the ball bearing with grub screws and

secure with superglue)

Superglue for screw locking

Cable tie

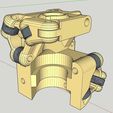

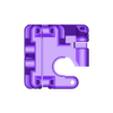

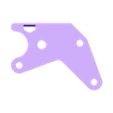

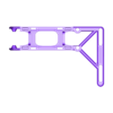

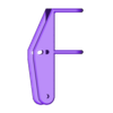

The gearbox:

Print worm with support

then remove the support and use grinding paste without the motor holder,

assembled on the drilling machine, at high speed.

Then clean and grease well.

Then connect the motor to the worm shaft via the 4/5 mm shaft coupling.

3D printer with cross kinematics, (Ultimaker system)

with ball-bearing print head on carbon shafts 8mm,

Direct extruder: 120 grams

with Bondtech double gears for 8mm shaft

0.9deg Round Nema 14 stepper motor 5Ncm 0.5A

2-track globoid worm gear 1X8

swiveling with cable chain

Filament guide with ball-bearing pulleys,

Ball-bearing:

Pcs ØA X ØI X width

20 X 7 X 3 X 2.5mm print head and pulleys

2 X 10 X 6 X 3mm swiveling print head

4 X 8 X 4 X 3mm gearbox and extruder

Screws:

Extruder with E3D V6 Hotend:

3 X M3X35 countersunk head

1 X M3X16 countersunk head

1 X M3X25 hexagon

Miniature shaft coupling (reduction) 5X4mm

Print head:

10 X M3X10

10 X M3X12

10 X M3X16

4 X M3X25

12 X grub screws 3X10

2 X grub screws 3X6

4 X grub screws 3X4

20 X M3 nuts

There are 2 adjusting screws per axis on the printhead for setting the

Clearance provided between bearings and shafts.

Screw in the set screws just enough for the bearings to still run smoothly

Axles carbon or metal:

2 X Ø 8mm length suitable for the printer, (for cross kinematics)

2 X Ø 4 X 45mm (for the gear)

1 tube Ø 6 X 20mm (extruder hotend connection via ball bearings)

1 X M6 snap ring (protection against slipping out)

2 passive heat sinks for motor

2 X silent fan 40mm (for hotend and component cooler)

3M thread cutter (cut 3mm thread into the Ø 2.6mm holes,

Mount ball bearings with grub screws and

secure with superglue)

Superglue for screw locking

cable ties

The gear:

Print snail with support

then remove support and use grinding paste without motor holder,

Assembled on the drill, grind at high speed.

Then clean and grease well.

Then connect the motor to the worm axis using the 4 / 5mm shaft coupling.

/https://fbi.cults3d.com/uploaders/16157685/illustration-file/d0530003-d4e7-43e4-bc26-23ec337746a8/20210212_064835-2.jpg)