Yet another dog feeder..

https://github.com/deadcrayon/dogfeeder/blob/master/main.py

The latest about this thing...

</h2>

<div class="justify justify-left">

I wanted the challenge of vertical feeding, I could have went with a horizontal feed screw, used a conditioning screw, and been done with it.. But I wanted the footprint of the feeder to only take up a small space in the corner. I could have also used a break beam or something else to detect the food falling down the tube, but lasers are much cooler.

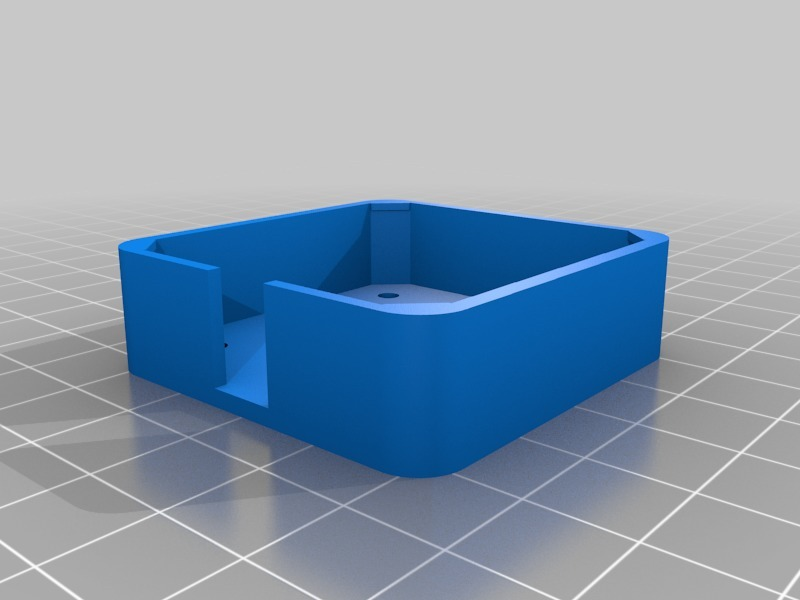

This thing has been through a lot of revisions. Still a few more to come. A few of the biggest problems have been the food bridging at the neck of the reducer and the food actually jamming the feed screw when theres more than 10-15 lbs. of food in the hopper.

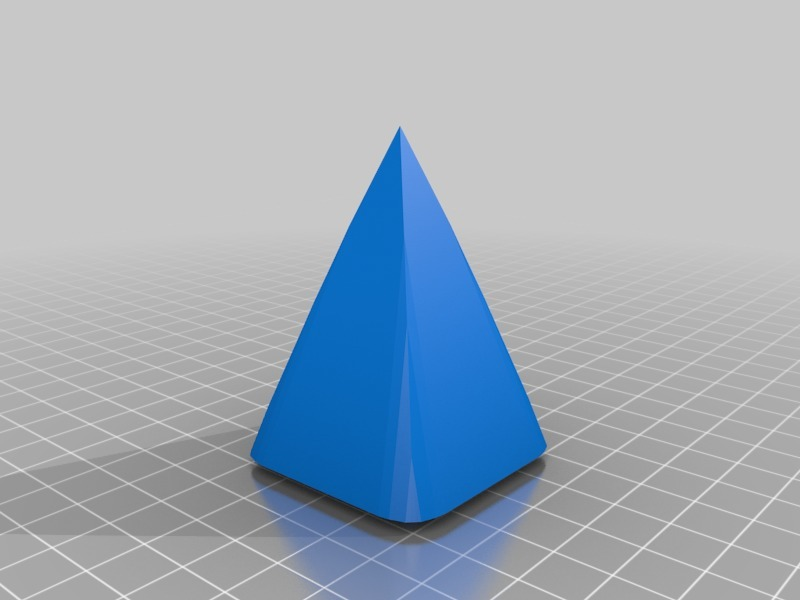

To address bridging since its a vertical feed screw I can't really do a conditioning screw on it, I went with a cone that is glued to the motor cap and then motor cap is black taped to the stepper motor, crude, but it works.

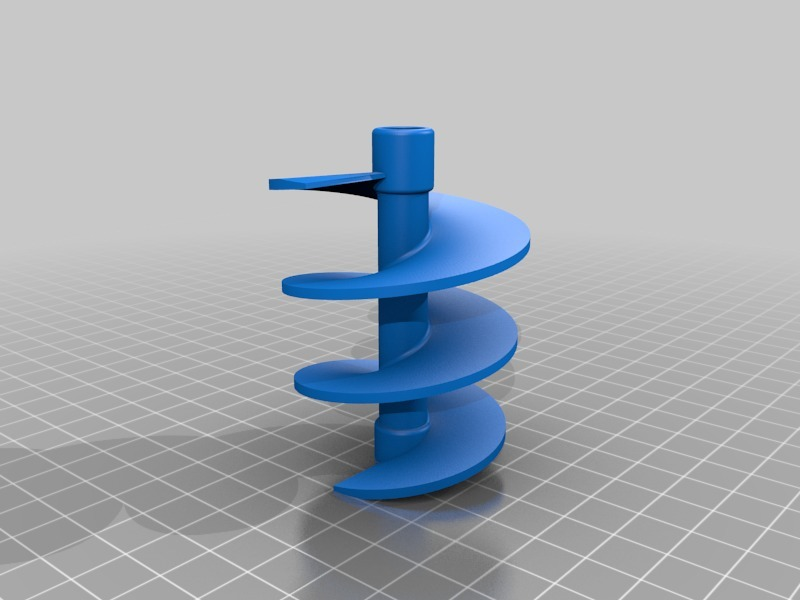

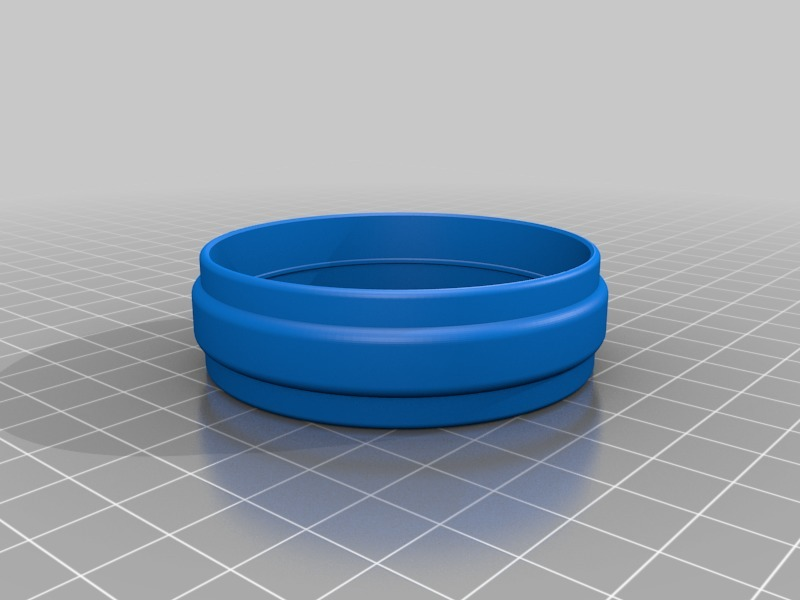

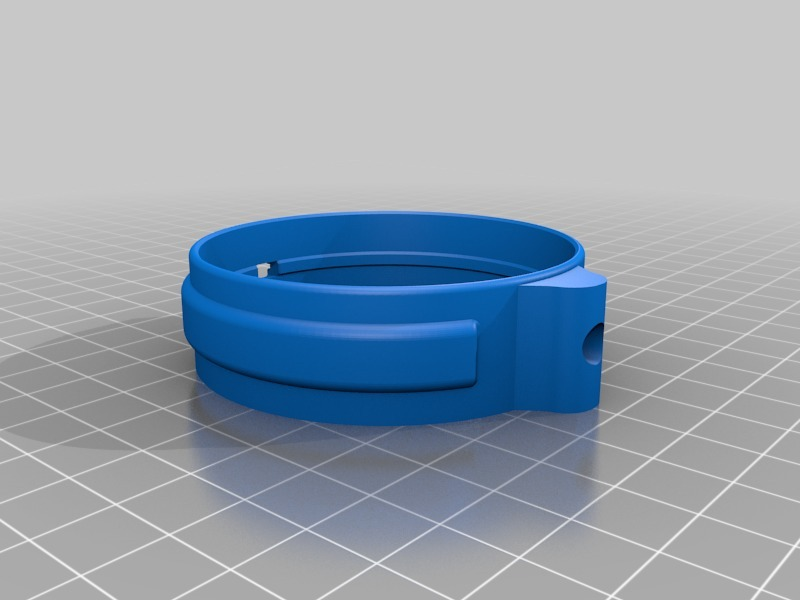

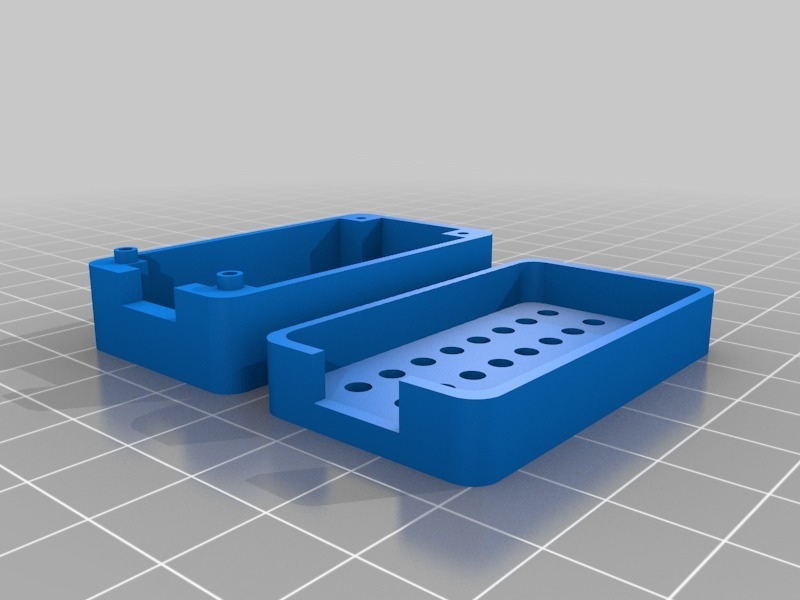

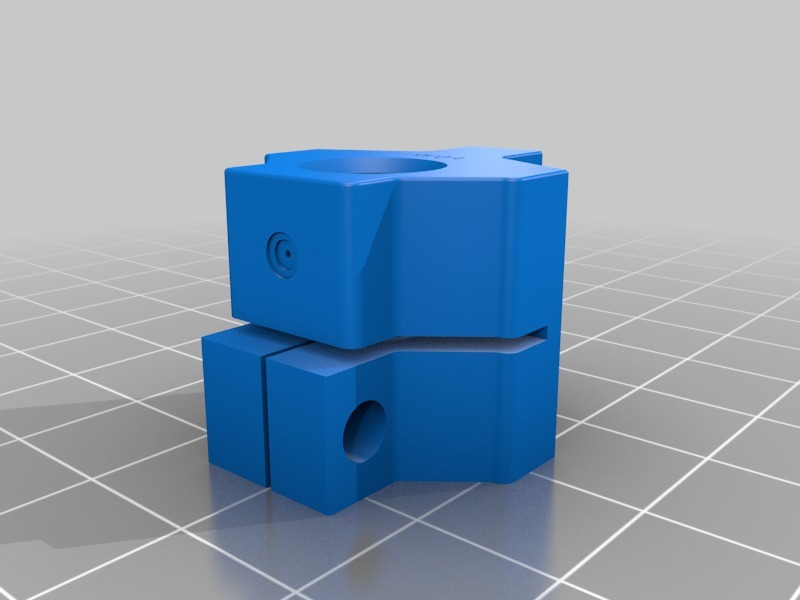

The jamming issue has been solved three ways; first, the feed screw has a -5 degree angle to decrease the size of the feed screw flights, this allows the food to eject faster from the feed screw. Second, the feed screw is mounted to a spring coupler (5mm to 8mm [pictured]), this allows the feed screw to flex and move within the reducer neck. Third, the 2" pvc pipes are outer flush joined (pvc coupler outside) instead of using the inner joining default pvc connections, this creates a flush surface inside of the reducer neck to prevent food from jamming.

So far, I've been able to add about 25 lbs. of food to the 4" pvc hopper and feed the entire hopper without jamming or bridging. There are some cases where, if you run the feed screw for a very short time not enough vibration is generated by the stepper to cause the food to collapse the bridge on the pyramid motor cap.

Non-printed items required/needed...

</h2>

<div class="justify justify-left">

Building this thing...

</h2>

Using the reducer jig, drill a hole and insert screw, drill second hole. Remove screw and slide jig around, insert one screw and drill other hole, repeat until 4 holes are drilled. Drill one additional hole 4mm below any other hole, this is for the wires on the stepper motor.

Attach stepper motor to stepper motor mount, feeding wires down through the mount.

Attach spring coupler to stepper motor, paying attention to set screw on d-shaft. Cut 8mm rod into 80mm length using 8mm rod vice jig. Insert 8mm rod into feed screw. This will require patience and a hammer, its made to fit tight. Careful not to shroom out the end of your rod.

Slide exposed end of rod into spring coupler and tighten, insert assembly into 4" reducer and insert m4x12mm screws into the 4 holes drilled earlier using the reducer jig, paying attention to feed the wires through the additional hole. Next, attach the cone to the rear motor cap (apply some glue to cone pins and let dry before placing on stepper motor) and affix to stepper using black tape.

Place the 4" pvc pipe (hopper) onto the assembly. This completes the feed assembly.

Next, using the pvc coupler and street elbows, you can route the food down from the hopper to your food dish.

</div>

This thing has this roadmap...

</h2>

<div class="justify justify-left">

Revision

Update

Status

Status Date

1.0.0

Fix rear motor cap and cone snap holes

Completed

Mar 03 2019

1.0.0

ESP8266 Code

Completed

Mar 03 2019

1.0.0

Laser Wiring Diagram

Completed

Mar 03 2019

1.0.0

Stepper Wiring Diagram

In Progress

Mar 03 2019

This thing requires programming (if using ESP8266), and wiring...

Top

<div class="justify justify-left">

First, I am making use of Micropython. You don't have to, you could easily convert to regular Arduino code, for example.

The code is fairly straight forward, basic stepper control. Once you start to get a reading from your photo-resistor, you can modify the settings in the code to align with the readings you get. I am sure they will be different than mine.

I am using a voltage divider to obtain the photo-resistor values via the adc pin. A serial plotter or OLED is helpful for plotting the readout of your adc pin. I don't suggest trying to read the values in WEBREPL, it tends to lag out when trying to scroll values (fast enough to matter on a serial plotter).

Wiring diagram for laser and photo-resistor.

</div>

</div>

/https://fbi.cults3d.com/uploaders/27685758/illustration-file/2834430d-21e8-4396-b4e1-5347a25729a3/Image_from_iOS_9.jpg)