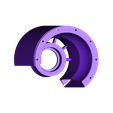

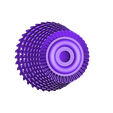

"Propfan Engine", "Open Rotor Engine" and "Ultra High Bypass Engine" were developed as "Advanced Turboprop Engine" to get the high flying speed obtaining about the same fuel consumption as "Turboprop Engine.

There are several type of engines as follows;

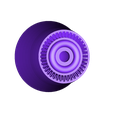

・"Puller (Retract) type" - Contra (Counter)-Rotating Propeller (Fan) with gearbox is located at front like as common turboprop.

・"Pusher (Un-Ducted Fan) type” - Contra-Rotating Fan "without Gearbox" is located at rear.

But the development of above type engine seems interrupted according to the noise problem, etc.

Please refer my creation: https://cults3d.com/en/3d-model/tool/propfan-engine-pusher-type

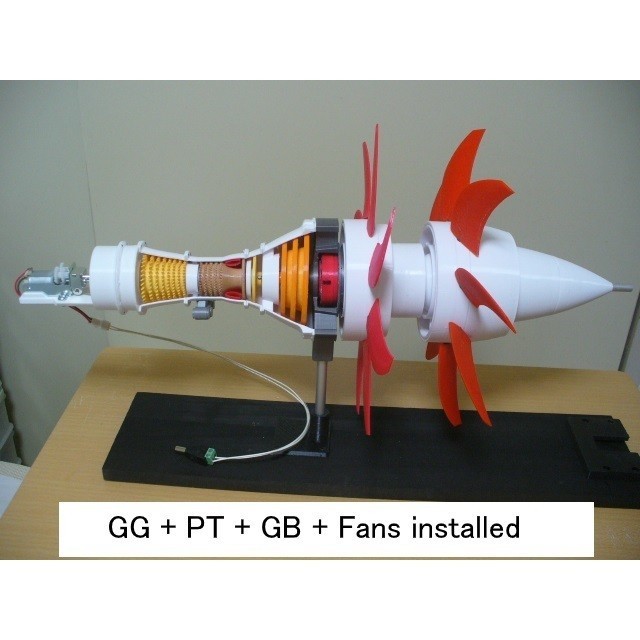

・"Pusher (Planetary GB) type” - Contra-Rotating Fan "with Gearbox" is located at rear.

This type would be recently developed in Europe.

I am very interest in "How it works", then I tried to make it.

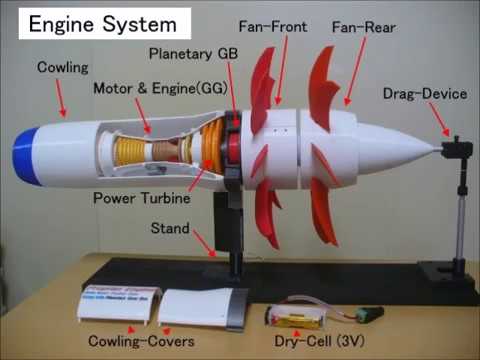

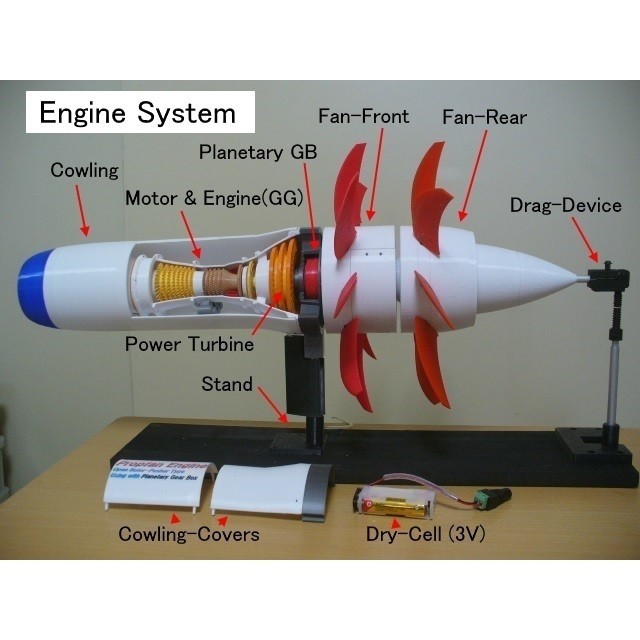

A. Features of this type engine;

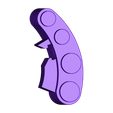

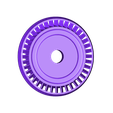

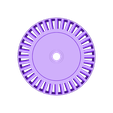

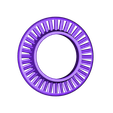

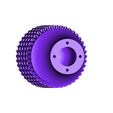

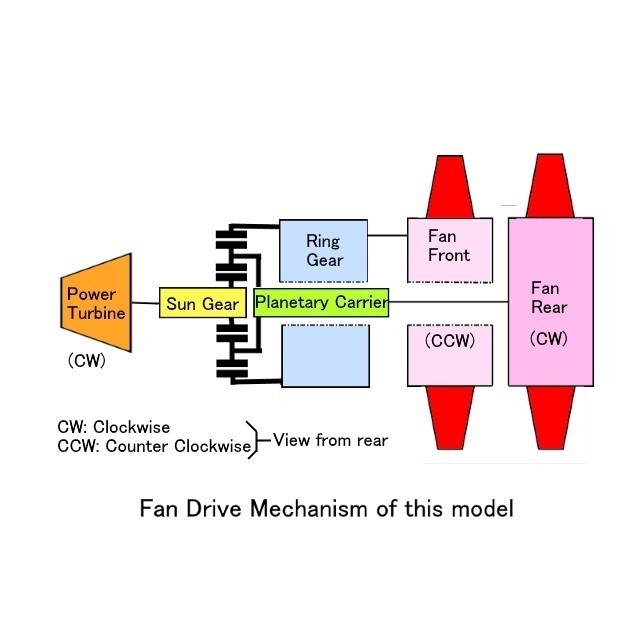

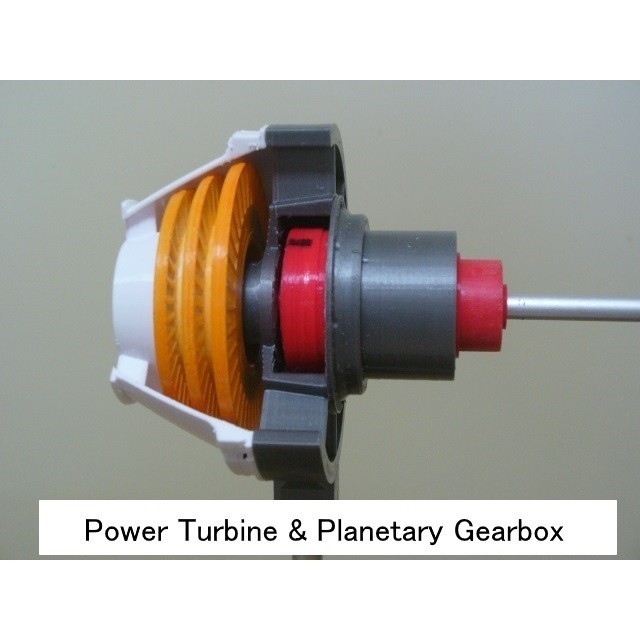

1. Power turbine is use to drive "Fans" thru "Sun Gear".

2. Planetary gerabox is used to make 2 outputs to drive "Fans" thru "Planet Carrier" and "Ring Gear".

3. Torque of 2 outputs are controled by each stage of "Fan Blade Pitch".

4. Blade Pitch Change Mechanism and Control Method (System) are very important.

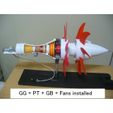

B. Features of this model are;

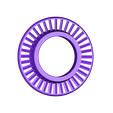

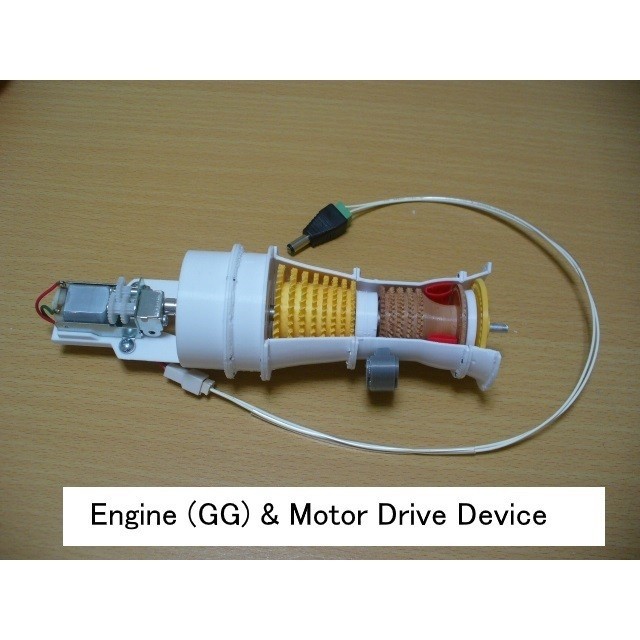

1. Power Turbine and Contra-Rotating Fan can be turned by a small motor with the dry cell.

2. Drag torque device is attached to apply drag instead of Blade Pitch Control.

Because, I can not make the pitch change mechanism.

3. Engine (Gas-Generator) cutaway model is inside of Cowling, but it is not rotated by the motor.

4. Entire engine cowling with removable cover.

Video: https://youtu.be/cq59D1QPtXE

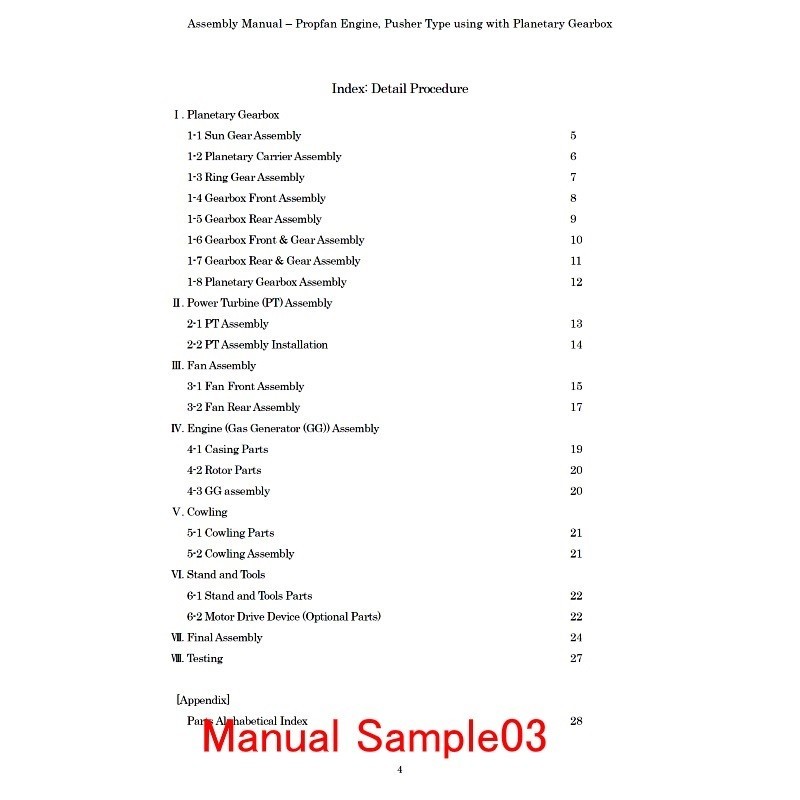

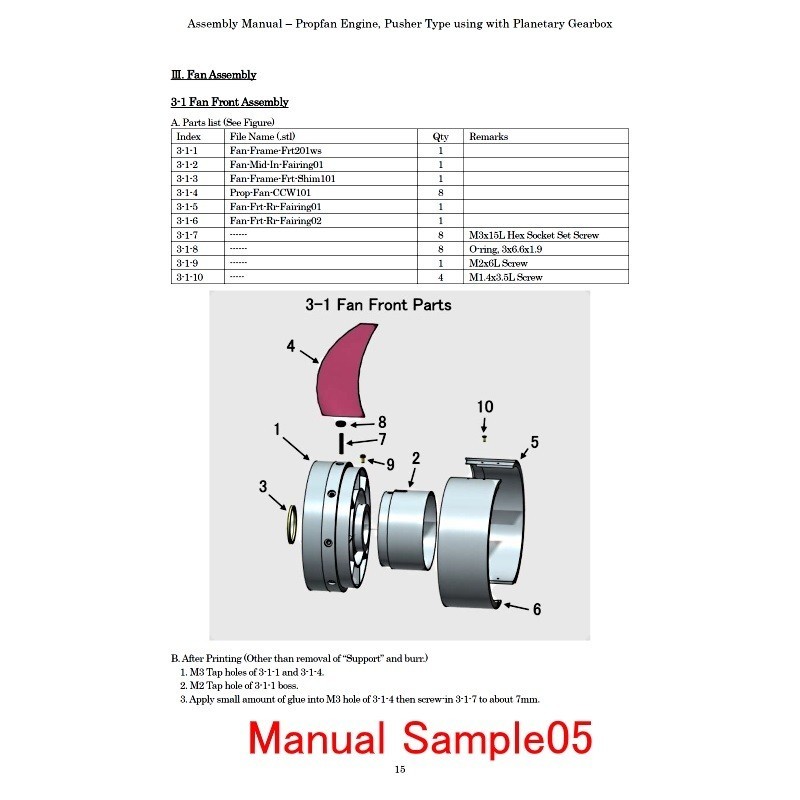

B. Assembly Manual (PDF format, total 30 pages)

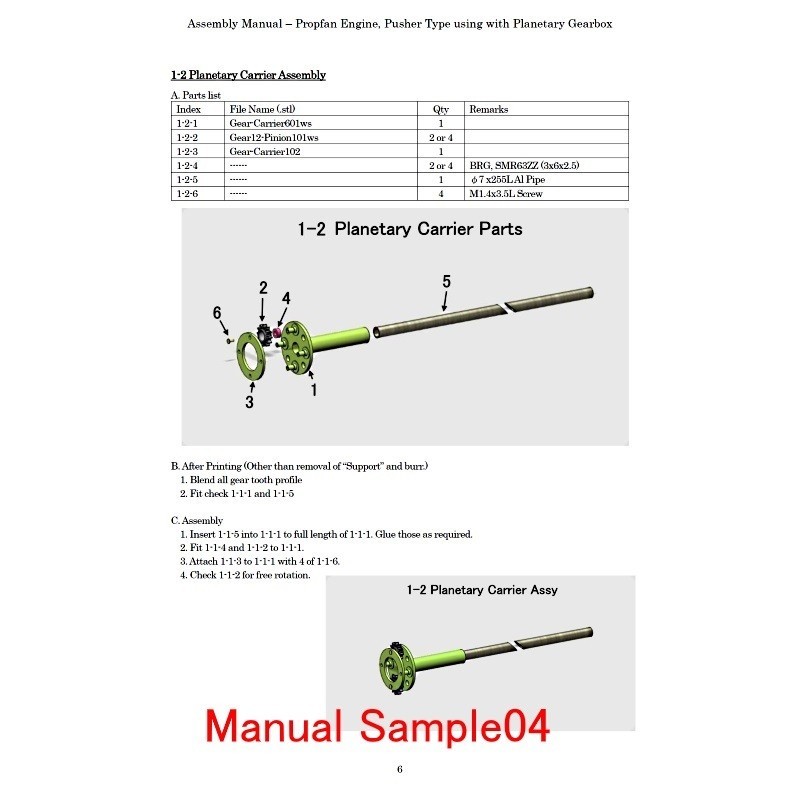

The detail assembly manual including "Parts-List", "After printing treatment" and "Assembly procedure" are prepared based on "Standard Skill (Filing, Drilling, Tapping and painting)".

C. General Notes

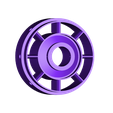

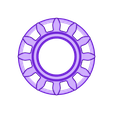

1. Bearing Selection

Bearings are very important parts to get smooth rotation. This model is based on using with following size "Open type" ball bearings because of low friction.

ID x OD x W = ① 9 x17x4 ② 10x19x5 ③ 25x37x7 ④ 3x6x2.5 - (every 2 ea.)

2. For M1.4 Screw

No need “Tapping”. Drill with φ1.0 drill then direct screw-in.

3. STL file name

“ws” of last 2 digits means “With Support” special designed.

Download files includes;

- files: STL Files (61 items)

- PDF(Zip) File: Assembly Manual

- images: Assembly Photos

Purchase Parts Information;

- BRGs

See Assembly Manual

- Aluminum Tubes

See Assembly Manual

- Screws

Micro screws M1.4x3.5L - Appox. 30 ea - Direct screw-in to 1 mm dia hole (No nut)

Screws M2 x ** - See Assembly Manual

- Motor is optional

Assembly Points

- Standard Skill (such as Drilling, Tapping, Filing, Tightening, Painting and Gluing etc) is needed and perseverance too.

- Blending and finishing of gera teeth are very important to get smooth rotation,

- Others: See Assembly Manual

Total Net Print Time: Approx. 130HR

- (Estimated as case of PLA, 0.4mm Nozzle, 0.2mm Layer Height, 40% infill and No raft and support)

Note: When at actual print, each parameter may be adjusted by your experience.

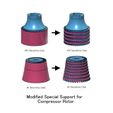

[Update 2019.1.4]

Mod. Rotors (HPC,IPC) added to STL and Manual as option.

[update 2021.10.11] changed a part and related Manual

Gear-Carrier102.stl → Gear-Carrier202.stl

Assembly Manual-01R2

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/8eaf7722-f2f9-4781-acf5-61420100fa99/00-Testing01.jpg)