###This is a set of files to convert a cr-10 mini to a kind of a Prusa.###

####Why this mod?####

I have 3 machines running like this, did it for the space saving and for the prusa extruder, I want to be able to use the same gcodes on all my machines and having the same physical extruder helps

In the end, if you are brave enough, you will have a cleaner cr10 machine capable of printing any material and with better print quality.

####Main Changes####

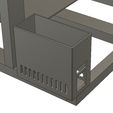

Board moved to back left

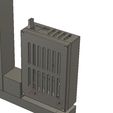

PSU moved to back right

lcd moved to front

SSR movet to the base of the psu box.

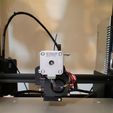

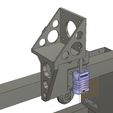

New prusa mk2 extruder system based on a modified prusa extruder part that will be screwed directly to the CR-10 X L plate. (2 holes and 1 embedded threaded removed)

####Heatedbed####

On my machines I use PEI directly over the aluminium bed, usually these beds have a depression in the center so a sledge is used, sometimes I use one of those thick bed springs at the center.

Ideally we would use a central screw but it involves drilling the bed and I haven´t had the courage yet.

So, since we have a fixed central point we inser the spring and then lower the other 4 points until the bed is flat and leveled. Then we set the Z endstop height.

####Extruder####

The best extruder is themodded Prusa, I´m including the modded part, the rest you can get from prusa website or guithub, its the MK2S version

There is another extruder bracket included that will allow you to use the original cr-10 hot end. I gave up that road but still included it here so it might be useful, it works fine with a 50mm radial fan blowing directly into the heatsink, not much refinement has been done on this.

If you are mounting the prusa extrudes the last picture shows the holes used to fix the extruder to the X-Carriage plate on the machine. You will have to use the printed part as a template to make the holes, align by the right side, use a clamp or a vise to secure and drill two 3mm holes.

The bolts will come from behind to the nuts that will be embed in the part.

You will use many of the embed bolts to secure the other extruder parts so don´t be afraid to assemble and disassemble several times until you find the right sequence to do it.

####Cooling fans####

The SSR will get the air pulled by the PSU fan

The board has no fans, it might be a good idea to install a fun sucking air in the outside of the box although I have printed long hours PLA and haven´t seen any significant temperature increase without the fans

The prusa extruder uses 2 fans, one 30X30mm and one radial 50mm

####Board####

My minis have the melzi 1.12 if I´m not mistaken. to make this mod work on a 10-s or a 10 you should check if your board will fit the board box.

####Wiring####

You will need to disassemble your printer, take pictures and take notes, don´t be a jackass!

The cables from the board to the extruder are hold with a thin steel sheet, the old fashioned one used to pass electrical wires inside the walls, its like 0.5mm X 5mm should be easy to find on ebay.

Wires are all reused, you will only need a bit of 16 awg silicone wire to power the board since the PSU will be in the other side of the machine.

Braided nylon sleeves are all reused..

####Needed Parts####

(That I can remember)

E3D V6 or Lite6 or clone

Prusa pinion tooth e3d also sells them but they are slightly larger than Prusa´s.

30mm bb fan 50mm radial fan

Some long m3 screws 40mm, 25mm and so on

2 springd for the extruder idler

1 PEI sheet?

2 10pin connectors

80cm of 10 conductor flat cable for the lcd

some 16awg silicone wire

spring steel guide for the extruder cable management

some M5 screws and T nuts

Some square M3 nuts

####LCD####

I use the LCD on my machines because I like the see the temperatures and such but it is not mandatory if you are printing via octoprint. (some people don´t know this)

####Firmware####

I use stock Marlin.

####Conclusions...####

I´ve used these printers to print repetitive parts, last time they worked for a week non stop, no problems whatsoever.

The last machines I modded took me one day of work each, there is much soldering, testing, assembling and disassembling...

####Change Log####

Added the Fusion360 files so anyone can mess around with the designs. Please re share!

Added .factory files and Gcodes for a prusa i3mk2s PET and ABS parts

Added the Prusa extruder holder (without Pinda holder version) This version is stronger, if you are not going to use a bed probe this is better than the other version.

/https://fbi.cults3d.com/uploaders/13630379/illustration-file/8ee7dc85-271a-4c24-a72d-078ab70fae7b/36426f8be484ed6d1da0b8312581863e_display_large.jpg)