Update

I have updated the parts as singles. They haven't been oriented for printing.

Z-nut.STL mount for the z-screw nuts. Print two, and mirror the second one.

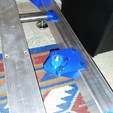

X-stop01.STL End stop switch mount for the X-axis. Adjustable.

Y-stop01.STL Tab for optical homing switch for the bed

Z-stop02.STL Holder for the optical homing switch for Z.

T-bracket01.STL T-frame gusset for the vertical frame. Print two, and mirror the second one.

Y-motormount.STL Motor mount for the Bed stepper motors. Print two.

Z-coupling01.STL Stepper motor coupling for the Z-screws. Print two.

X-LH.STL Left X-axis.

Filamentholder01.STL Filament roll holder for the top frame. Print two.

X-RH.STL Right X-axis.

PrinterKit01.stl Complete parts kit for the printer.

Elbox01.STL Electronics box bottom.

Corner01.STL Corner piece for the frame assembly. Print two.

Display04.STL Display holder.

Carrier01.STL Extruder carrier and hot end clamp.

Extruder01.STL Extruder part.

Powercover01.STL Cover for the power supply.

Grip01.STL Belt grip for the extruder carrier.

Grip02.STL Alternative belt grip for the extruder carrier.

Corner02.STL Corner piece for the frame assembly. Print two.

bearing02.STL Bearing assembly for the bed. Print four.

bearing01.STL Bearing assembly for the extruder carrier. Print three.

Fanshield01.STL Shield to deflect plastic cooler fan flow. Print two.

Fanholder01.STL Holder for hot end cooler and plastic cooler fans.

Corner03.STL Corner piece for the vertical frame assembly. Print two.

Extruder02.STL Extruder lever.

Stop02.STL Display stop button.

Tiemount01.STL Zip tie mounts for organizing cables along the frame. Print as many as necessary.

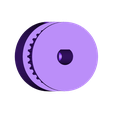

Pulley02.STL Stepper drive pulley. Print three.

Pulley03.STL Idler pulley with bearing spacer. Print two.

Elbox02.STL Electronics box top.

Y-stop02.STL Holder for optical homing switch for the Y-axis.

Stepperdummy.STL Stepper dummy if using one stepper on the bed axis. Two steppers are recommended.

Y-shaftmount.STL Y shaft mounts. Print four.

Z-stop01.STL Tab for the optical homing switch for Z.

Y-beltgrip01.STL Belt grip for the bed.

complete.STL An almost complete model of the assembled printer.

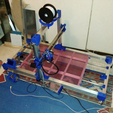

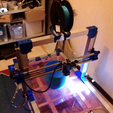

Here are the parts for my Mammut (mammoth) printer. It has a moving bed, which I was sceptical about at this size, but it works great. The reason I tried a large moving bed was to use stuff I had lying around that would lend itself to that kind of configuration. I now run two motors on the Y-axis for extra power.

I will not provide detailed assembly instructions, so don't start building iit if you don't feel that you can do it on your own. It should be self explanatory to experienced makers using the pictures provided. You may need to change some things to suit your part selection in case you don't have/can get hold of the same stuff. Just do it.

The part file includes all the parts in one file, so you don't have to download fifty different files.

The bed is made from a 40x20x2mm aluminum rectangular tube, split in half along the length, and five 90° angles. The surface is a sanded 4mm acrylic sheet, 800x520 mm.

The parts include a holder for a smart controller LCD display (mine was from Sunhokey) and a MKS Gen V1.2 controller board with A4988 drivers. The Newest version is V1.4:

https://www.banggood.com/MKS-Gen-V1_4-3D-Printer-Control-Motherboard-Compatible-RepRap-Ramps1_4-p-951136.html?p=HD240528697332015103&cur_warehouse=CN

https://www.banggood.com/10Pcs-3D-Printer-A4988-Reprap-Stepper-Motor-Driver-Module-p-955808.html?p=HD240528697332015103

https://www.banggood.com/3D-Printer-A4988-Reprap-Stepping-Stepper-Step-Motor-Driver-Module-p-88765.html?p=HD240528697332015103

The pulleys are 2mm pitch. I use them with GT2 belts with no skipping despite being printed:

https://www.banggood.com/10M-Rubber-GT2-Open-Timing-Belt-Width-6mm-For-3D-Printer-RepRap-p-1148503.html?p=HD240528697332015103

The linear bearing blocks take 3x10x4 mm ball bearings. A total of 28 bearings is needed:

https://www.banggood.com/10pcs-623-ZZ-3x10x4mm-Deep-Groove-Ball-Bearings-Miniature-Bearings-p-81182.html?p=HD240528697332015103

The linear rails for X- and Y are 3/4" (or 19mm) stainless steel tubes. I'm sure other rods or tubes in other materials will work as well as long as they are 19-19.05 mm (3/4") thick. 2x700 mm and 2x1220 mm are needed.

The rails for the Z are 500 mm long SBR16 supported rails, with four LME16UUOP bearings. These bearings are the 26 mm outer diameter kind, and not 28mm:

https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2F1pcs-LME16UUOP-16mm-Open-Linear-Ball-Bearing-16x26x36mm-for-3D-Printer-CNC%2F263224706711%3Fhash%3Ditem3d496a4697%3Ag%3A3HIAAOSwjL5ZJpBm

Rails:

https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2FLinear-Shaft-Rail-Support-SBR16-L500mm-Rails-Support%2F351705115619%3Fhash%3Ditem51e3422be3%3Ag%3AzoQAAOSwq19XC0DE

The frame is made from plastic gussets and 40x40x2 mm square tubing of the following lengths:

2x1300 mm for the lengthwise pieces.

3x620 mm for the ends and top. The ends would benefit from being made from steel instead of aluminum.

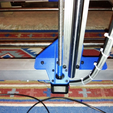

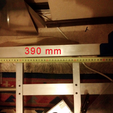

2x500 mm for Z. These are installed on the side frames at a distance of 390 mm from the front end gusset, as one photo shows.

2x500 mm long 8x8 mm lead screws with nuts are needed. They will fit into the Z shaft adapters:

https://www.banggood.com/500mm-Lead-Screw-8mm-Thread-2mm-Pitch-Lead-Screw-with-Copper-Nut-p-982941.html?p=HD240528697332015103

I use a chinese E3D clone with a home made Volcano hot end. The fans for the hot end are 40x40 mm for the cold end ccooling, and two 35x10mm blower fans for PLA cooling:

https://www.banggood.com/Volcano-Hot-End-Eruption-Heater-Block-Heating-Block-For-3D-Printer-Accessories-p-1014475.html?p=HD240528697332015103

https://www.banggood.com/Heatsink-12V-0_1A-2-Pins-CPU-Cooling-Fan-PC-Computer-40x40x10mm-p-920618.html?p=HD240528697332015103&cur_warehouse=CN

https://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_id=114&ipn=icep&toolid=20004&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2F1pc-NEW-Delta-BFB03505HA-35x35x10mm-35mm-3510-5V-0-17A-DC-Brushless-Blower-Fan%2F221214013657%3Fhash%3Ditem338161f8d9%3Ag%3AgxcAAMXQLbVRaf6C

This fan can fit with some modification:

https://www.banggood.com/Aluminum-Heatsink-Cooling-Fan-For-LattePanda-Matching-Acrylic-Case-p-1092769.html?p=HD240528697332015103&cur_warehouse=CN

I use 92 oz in/65 Ncm steppers for X, Y and extrusion, and smaller motors for Z. The 30 tooth pulleys on X- and Y need strong motors, and allow high travel speeds of up to 300 mm/s.

A ~11 mm extruder gear is needed:

https://www.banggood.com/2Pcs-MK7-MK8-Extruder-Driver-Feeder-Gear-Wheel-40Teeth-11mm-Bore-5mm-For-3D-Printer-p-1036149.html?p=HD240528697332015103&cur_warehouse=CN

X uses a microswitch for homing. Y and Z uses PiBot optical end stops for homing. Parts are included for installing all switches. X- and Z-switch brackets are attached to the frame with high strength double sided tape and provide a large enough contact area to give a very secure attachment:

https://www.banggood.com/10Pcs-AC-250V-15A-V-156-1C25-SPDT-Roller-Lever-Micro-Switch-p-944613.html?p=HD240528697332015103

/https://fbi.cults3d.com/uploaders/384187/illustration-file/7caa6d4a-8528-452f-ba16-e772a1315797/Capture%20d%E2%80%99e%CC%81cran%202016-10-17%20a%CC%80%2010.49.33.png)