Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

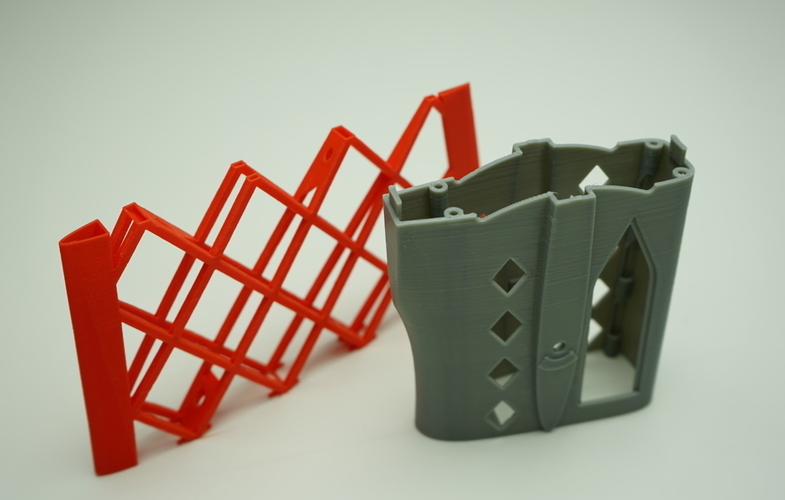

This is piece of horizontal stabiliser and piece of fuselage from 3D printed RC plane KRAGA Maripi. If you are able to print this part you should be able to print whole plane.

KRAGA Maripi is 1.1m big acrobat which is printed on 3D printer and reinforced with carbon spars.

More info at https://www.3DprintedRCplanes.com/maripi

Video of assembled plane: https://www.youtube.com/watch?v=T8RgL5h8tJ0&t

The file is available also here: https://3dprintedrcplanes.com/download_test/maripi/

Rafts:

Yes

Notes:

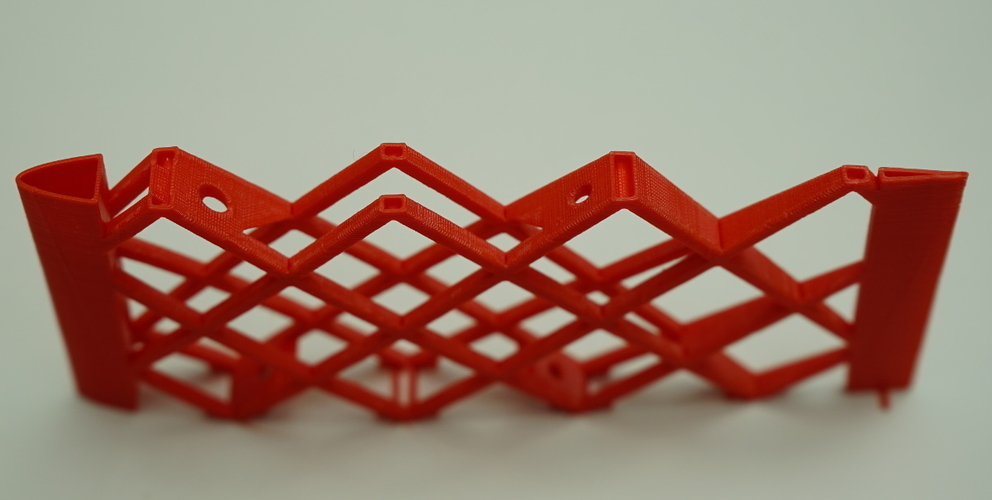

The red one has to be printed as shell - 0% infill and no horizontal surfaces (thickness of the shell is one layer). Only this way you can achieve required weight of the plane.

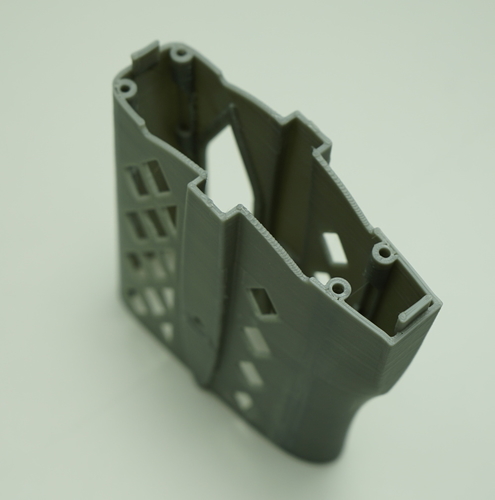

The grey one has to be printed as solid - 100% infill.

Nozzle: 0.4 mm Layer thickness: 0.19 mm Rafts: yes Use the default orientation and whatever printing material.

Result verification

Red part should weight 8 g. The wall of the shell should be printed by one pass of printing head so that the shell is very thin. You should be able to fit carbon tubes with diameter of 3 mm and 2 mm into spar leading holes.

Grey part should weight 16 g and you should be able to fit carbon tube with diameter of 2 mm into all 4 spar leading holes. There might be small printing imperfections making it difficult to insert carbon spar all the way through the part but in written build guide I'm describing a way how to clear the holes using for example a spoke from bicycle wheel.

I strongly recommend to cover both parts with covering film to test if material of your choice will not deform from ironing heat and if covering film will stick on it (I tested many materials with multiple covering film brands without issues but it can theoretically happen).

Comments