Titan Aero carriage for D-bot

Remix of the AC-Bot Carriage 2.0 by Sparreau

####Modified to allow for 26mm or longer stepper motors.

*Big thanks to Sparreau for the original design and Fusion360 files. *

https://www.thingiverse.com/thing:2822853 (https://www.thingiverse.com/thing:2822853)

#####Features of original:

1. E3D Titan Aero mount

2. 3 wheel X carriage with adjustable tensioner

3. Adjustable belt tensioners

4. Mount for C shaped cooling shroud using 50mm blower

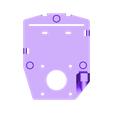

5. BLTouch probe mount

#####Modified the original files with following:

1. STLs rotated for print orientation

2. Added sacrificial bridge layers to the unsupported bolt through holes. No supports needed now. Just cut the bridge layer out with a knife or drill.

3. Modified the rear plate to hopefully fit 26mm stepper motors commonly used with the Aero.

#####Update April 4:

1. The front plate got mirrored somehow. If you've printed it, sorry about that. The corrected file has been uploaded now.

2. I've also noticed that the nut pocket for the fan shroud on the 26mm stepper backplate may not be deep enough for the average M4 nut. To save space I'll probably replace the nut pocket with just an M4 thread.

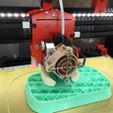

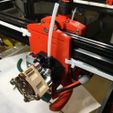

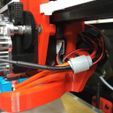

3. Added some photos of first test prints in PETG.

#####Update April 4 part 2:

1. I've uploaded a new back plate for 26mm steppers. It was pretty tight before. There should be about 27mm of space now.

2. The nut pocket has been changed to a modeled M4 thread. The shroud isn't heavy and the other nut pocket would probably be enough to hold it securely anyway, so this one is more to keep it from rotating at all.

#####Update April 5:

Uploaded a modified fan shroud that

1. Gives more clearance for 26mm steppers

2. Uses a bit less plastic

3. Has a slightly larger opening for the blower

4. Has a more forgiving bolt hole for securing the blower

#####Update April 11:

Uploaded a new version of the rear plate and fan shroud with complete clearance in case you wanted to use a stepper motor longer than 28mm.

#####Update April 18:

Uploaded a new version of the rear plate that specifically fits the E3D Slimline 25mm stepper motor which has a flared out section where the cable connector meets the stepper body. This flare made it impossible to fit front and back together. There is now a cutout along the arm that drops down for the shroud holder. See photo for orientation.

#####Update April 19:

After doing a test fit assembly I realized that the shroud was too low on my setup making it equal in height to the nozzle tip. I've adjusted the rear plate to raise the shroud by approx 2mm. I'll do a test print and if it works out I will upload the file.

#####Update April 20:

Uploaded file for rear plate that raises the shroud 2mm bringing it in line with the clearance for the BLTouch pin. Printed and tested working.

I've noticed that the belt tensioners are slightly further back and pull the belt slightly out of alignment with the idlers on the H arm ends. It's unclear to me if it's enough to cause an issue. Towards the center of the plate probably very little. If it ends up being a problem I think I could modify the idler blocks and the backpack and rear plate to move them farther forward.

####Hardware Used:

- M5 40mm x2, M5 35mm x1, M5 hex nut x3 for the wheels

- V-slot mini wheels x3

- M4 30mm x1, M4 washer x1, and M4 hex nut x1 for blower mount

- M4 12mm x1, M4 8mm x1, M4 washer x2 and M4 hex nut x1 for fan shroud mount (26mm stepper)

- M3 16mm x2 and M3 hex nut x1 for belt tensioner blocks

- M3 20mm x4 and M3 hex nut x4 for wheel tensioners

- M3 12mm x2 and M3 hex nut X2 for backpack

- M3 8mm x2 and M3 hex nut x2 for BLTouch mount

- M2 12mm x2 for micro switch

####BLTouch Nozzle Offset

X: -41.8mm Y: +32.2mm Z: +2.3mm

You should remeasure the Z height to be accurate to your setup.

/https://fbi.cults3d.com/uploaders/13561092/illustration-file/9b8e000c-bd17-41e7-b29a-87ba707eb0f1/0ee522cfd3bdcd4b0b68f12a8a289f93_display_large.JPG)