June 2017:

News!!!

The rudder assembly has been reworked to allow for a change in the pitch angle. I mounted two servos and mix them (V-tail program on the transmitter). You need two 624ZZ 4mm x 13mm x 5mm ball bearing.

I added a new set of back foils (symmetrical) as well.

The boat is much more stable now!

I think that if you don't want to add the relative complexity of a mixing servos, it should work just by setting up the proper angle and fasten it in place.

Thanks for your comments and I hope that you guys will build it, it's a great project!

https://www.youtube.com/watch?v=FkvLngxzD9I

https://www.youtube.com/watch?v=wZ5s8Pop9LE

https://www.youtube.com/watch?v=rXsFfcyyV-E

July 26th 2015: This is my latest attempt of a RC hydrofoil.

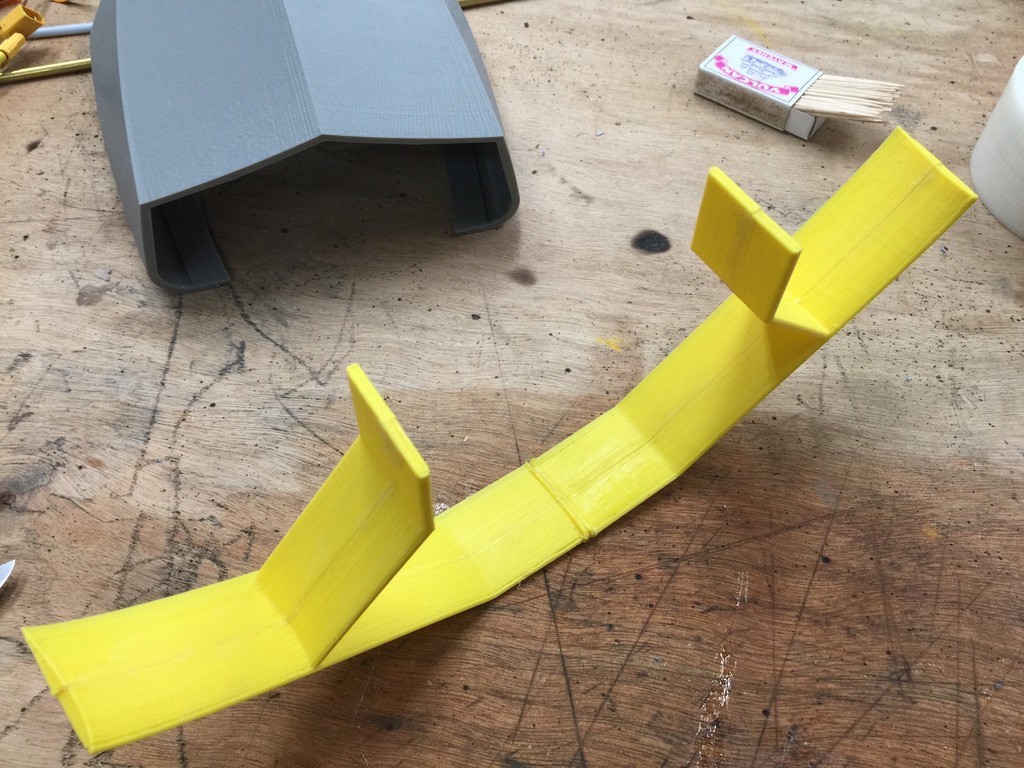

The profile is a Naca 63-412 (both front and back foils). The back foil has a 5deg dihedral for lateral stability. It's in two parts, glued together, in order to print the part without support.

The foiler is actually flying but on a very narrow speed range. Enough to make it lift itself and not too fast otherwise the prop is reaching the surface and starts to cavitate.

I would really appreciate any suggestion to improve it.

As mentioned previously, I’m working on a new hull, in four parts of max 15 cm so it would be printable on a variety of printers. Keep you posted.

Penny Express – Not 1898 pennies, but just one riding in style!

This is my entry to the MakeItFloat challenge.

I always wanted to make a RC hydrofoil, so what a great opportunity.

This is my first real project with 123D Design and 3d printing and I can tell you that I learned a lot.

This boat can theoretically carry 1’898 pennies, but I decided that only one would ride, so I had to find a very special place.

After 6 weeks of endless nights and weekends, about 100 hours of total printing time three prototypes and almost 40 iterations, what I expected to be a simple project finally started to lift up two days ago (video here; https://youtu.be/DgALh0y2N18).

I tried every thing that I can think of; changing the foil profile, size, angle without much success. I truly experimented Thomas Edison quote: “I have not failed. I've just found 10,000 ways that won't work.”

I wanted to do a simple boat, with an air propeller as propulsion with basic RC equipment, but my first prototypes acted more like fast diving submarines that flying boats. They were too heavy, too unstable and too small. I finally went for a more conventional marine setup. The hardware is easily available in any boat hobby shops.

In my latest prototype I reduced the thickness of the hull from 3mm to 1,6mm and almost double the overall size. It looks great and flies well.

This model is easily modifiable; the foils just interlock in the hull and can easily be removed and changed. There are 15 parts altogether and they can be printed without rafters or supports (PLA) in any printer that can print in a volume of 18cm x 18cm x 18cm. I will update the files to be printable on a 15cm height printer.

The hull of the latest version is in three parts that are glued together using 5 minutes epoxy. The front foil is in four parts allowing to print a large foil (modified Naca 4412-33 profile).

There are almost no RC hydrofoil models or plans available and very limited info on them, so I hope that this project will serve as a base for any one interested in pushing it further.

Thanks’ a million for the learning experience and having make an old dream come true!

/https://fbi.cults3d.com/uploaders/13782649/illustration-file/69b6b49c-85a4-452b-bc75-4a8650ea26b5/001_penny_express_display_large.jpg)