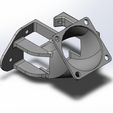

This is a surprisingly simple-to-print hot end fan mount upgrade for the TEVO Tornado. It uses the original two fans that are already on the stock hot end and is very simple to attach onto the X-carriage.

It has several advantages over the hot end fan apparatus holder thing (the metal cage that holds the fans on the Tornado) that the printer comes stock with. First, it directs the airflow only onto the heat sink, not onto the hot end unlike the original setup, allowing for more stable temperatures and a greater efficiency (if you care for that). Second, it positions the heat sink fan higher above the print and angles it away from the bed, seriously decreasing the chance of it sucking up strings from the print.

Something to be mindful of is that I have a Tornado that was bought in mid 2018. The design for the Tornado is slightly different with different iterations that TEVO sales, and so if you have a significantly older or newer Tornado, this fan mount might not work for your model. Unfortunately I can't test this fan mount on other versions of the tornado, and so if you have a TEVO Tornado that was bought during a different time, please provide some feedback for this design by posting a make of it that tells if it works or not. If I had to guess (which I am), I bet all the models of the tornado that are newer than mine will accept this upgrade.

****Build Instructions****

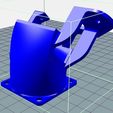

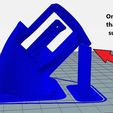

For printing, position the fan holder so that the face which holds the bigger fan is flat on the print bed. If you have trouble orienting the model, here are the angles of rotation I had in Repetier:

X:225

Y: 0

Z: 180

You do need to use supports, but only for the edge of the mounting plate section (notated in one of the pictures above). To achieve this, set your support threshold to 15 degrees. Also it is ideal to use a brim with the print because it has fairly small base on the print bed. It's ideal to use ABS because of its ability to withstand heat better than PLA. But if you have to, PLA should work well, but in the long run you might notice some sagging in the part

For assembly, begin by taking apart the original fan mount. Be careful to keep track of your screws because they're the only ones you have. First unscrew the screws that mount the entire fan mount into the X-carriage. Next take out the four screws that hold the heat sink fan in place and the ones that hold the part cooling fan in place. Notice that there are two different sizes of screws used for the part cooling fan; the larger ones correspond to the lower holes. You'll also see that the vent on the end of the part cooling fan falls off without the screws keeping it in. Now carefully separate the fan wires 3-4 inches out of the wire tube thing that holds all the wires that go to the hot end together.

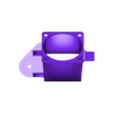

Slide the part cooling fan vent into the part cooling fan and slip the screws through the bottom holes on the fan, holding the vent in place. Now screw on the "Part Cooling Fan Screw End" model onto the bottom two screws you just put into the part cooling fan. You can see this part in some of the pictures.

Before you mount the part cooling fan, mount the heat sink fan. To do this, orient the fan so that it is still facing the same way as before (the label facing the heat sink), but this time the screws are going to go into the other side of the fan than before. It's a good idea to put the screws into the fan in this orientation before mounting the fan and then take them out. That way, the screws can press their threads into the fan's plastic and make for easier screwing in when you mount the fan. When you put the two bottom fan screws in, they won't go in all the way without hitting the fan duct. That's OK, as long as they keep the fan secure. So only screw the bottom screws on the heat sink fan until they hit the fan duct.

After you mount the heat sink fan, mount the part cooling fan by screwing the top two screws into the little arm on the right of the model. Turn the screws so that they are tight, but be careful not to bend the plastic on the fan.

Now the new fan mount is ready to go onto the X-carriage. When positioning the fan mount onto the X-carriage, make sure that the hot end wires are held back by the little arm on the right which the part cooling fan is mounted to. Now line up the holes on the fan mount with those on the X-carriage and screw the remaining two screws into place.

After you finish the whole process, it's best to do a PID tune on your printer because the previous PID tune is accounting for the heat sink fan blowing on the hot end. There are a lot of videos on doing a PID tune on Youtube if you don't know how to do it.

Most things are easier said than done, but after typing this ridiculously long set of instructions, I can say the opposite is true for attaching this upgrade! Happy printing!

/https://fbi.cults3d.com/uploaders/13523825/illustration-file/7a4904e5-2da9-4721-80c2-eee6b8ce23c3/ef166b8e758303eac4274899a441e196_display_large.jpg)