3D model description

UPDATE: An additional .stl file (5G+ Std Guide Tube.stl) has been added for 5th Gen owners with a Smart Extruder+ wanting a shorter filament feed path and less filament feed resistance. This type uses the standard filament guide tube which can be shortened by approx. 30% and will be a straighter feed path. No extruder cap fitting is required with this version. Just follow the filament drawer modifications. shorten the guide tube and your ready to go...

Please read the following overview / instructions:

The filament feed system on the 5th Generation Replicator is not a free or smooth as on the earlier Replicator 2's. Having as little resistance along the feed route ensures the right amount of filament is delivered on demand and also that there is no resistance that could affect retraction. In addition, this may improve reliability and reduce wear within the Smart Extruder due to reducing the internal stresses caused through pulling filament into the Smart Extruder (i.e. may improve service life).

This modification was developed to reduce the resistance along the 5th Generation filament feed route. (The route travels up from the spool then out of the filament drawer via a small hole followed by a fairly tight bend, along the back of the machine, through another bend then out through the front of the drawer before travelling through a considerable length of guide tubing before angling into the top of the Smart Extruder). In addition, the 5th Generation guide tube is considerably smaller so more restrictive than the tubing used on the earlier Replicator 2.

After this modification is carried out the filament route will essentially be 'straight up and over' like on a Replicator 2. The tubing used is from a Replicator 2 (although a fraction longer Teflon tube would be better).

The modification is relatively easy to carry of but does require drilling two holes in the drawer of a 5th Generation Replicator. Once drilled the printed parts can be installed in a matter of minutes along with a Replicator 2 guide tube (or similar) and use of 10mm cut from the original 5th Generation guide tube.

3D printing settings

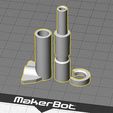

On a Replicator 2 the parts required for this modification were printed with Raft on, 4 shells and 50% infill at 0.20 (Std.) resolution. Printing on a 5th Generation Replicator should be similar.

Additional requirements:

(1) A Replicator 2 Filament Guide Tube (Teflon 6.0mm OD / 4.0mm ID / 50cm - 52cm long)

(2) A 10mm piece cut from the original 5th Generation Guide Tube

Tools:

Drill bits up to 10mm

Reamer and round file

Process (Refer to instructions on images):

(1) Remove the drawer from the rear of the machine

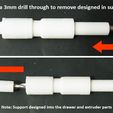

(2) Carefully work out location to drill the two holes (Through top of the drawer and up from the spool area so holes are in alignment (Make sure clearance is allowed for moulded support surfaces under the top surface of the drawer). Suggested location measurements are shown in the images provided.

(3) Starting with a small drill (2mm) progressively drill holes in both surfaces out to 6.5mm.

(4) Continue to drill out the hole on the top surface of the drawer until it is a 10mm hole (leave the lower hole into the spool area at 6.5mm). As a suggestion, large drill bits used on a power drill can be very 'aggressive' on thin plastic surfaces so try drilling it out using the drill bit in your hand with a cloth wrapped around it. This will minimise the risk of damage/mistakes.

(5) Clean up holes with a reamer and/or round file until the printed insert slips in easily and turns freely.

(6) Attach the printed circlip as a retainer so the inserted piece cannot lift out.

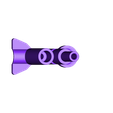

(7) Place the piece (10mm) of 5th Generation Guide Tube cut from the original guide tube into the top of the Smart Extruder. This will help ensure the filament is correctly aligned as it enters the top of the Smart Extruder.

(8) Place the printed extra cap onto the top of the Smart Extruder (Refer images)

(9) Reinstall the drawer with a spool of filament.

(10) Install Replicator 2 (50cm) or slightly longer (52cm ideal) Teflon guide tube from rear insert onto the new Smart Extruder cap.

(11) Load filament and print....

Note: The larger diameter, shorter length and more direct route of the replacement filament guide tube should minimise resistance of filament feeding. The tube needs to be PTFE/Teflon with a 6mm Outside Diameter / 4mm Inside Diameter / min. 50cm length.

/https://fbi.cults3d.com/uploaders/14164506/illustration-file/797f82ef-a59f-40dc-933e-410464bf48fe/main_display_large.jpg)