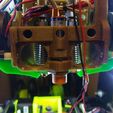

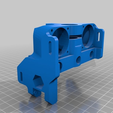

This is my compact version of my other Anet A8 dual extruder heads. This uses two E3D extruders and has bed leveling sensor mounted as close as I could possibly get it.

Now i had nothing but bad luck with these sensors and this is my last design to use them. They are pretty much garbage. Constant failures, barely repeatable results where I have never had BLTouch die and the results are always perfect. Please consider a BLTouch and the newer designs.

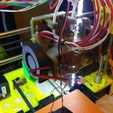

Here's the build timelapse!

https://youtu.be/tFMRo3YnjW0

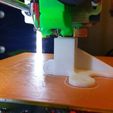

This is the front mount sensor version! Everything FITS!

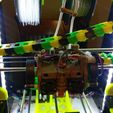

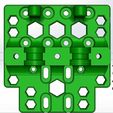

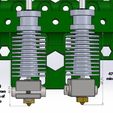

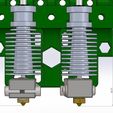

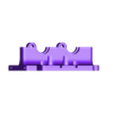

You can see in the last 4 photos that the head does not heat up much. It's been prionted in heat change PLA that shifts brown to green at about 35c. Hour into this print and it's barely changed since the cold air from the fans passes through the print.

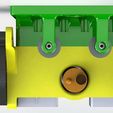

I made this one to put the sensor as close as possible to the heads. I think this is the tightest it could possibly be.

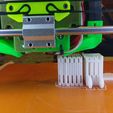

It has built in cooling ducts for the extruders and mounts for the stock 30mm fans built in. I used Mistral 2.1A 4.5 from www.thingiverse.com/thing:2121279 (http://www.thingiverse.com/thing:2121279) as my cooling ducts. You need to mirror one for the other side but they fit and work great. In theory this should fit any Anet A9 fan duct.

The back is just the no sensor one from my other mount: https://www.thingiverse.com/thing:2734717

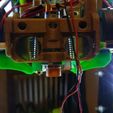

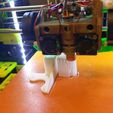

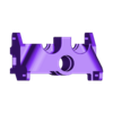

The fan spacers are included to help clearance the fans. Different ducts fit different ways but with the one listed above I found 2 spacers on ear screw worked great. For the lower screw on the side fans be sure to put it through the mount first then spacers and fan with the nut on the fan so it clears the 30mm cooling fans in the front. See pictures!

The three clamping screws use Socket Head M4x30 or 35mm with nuts. The head cannot be hex like a bolt or it will not fit in the recess. I found socket head best for torque and easy of use. For the fan mounts I used M3x30m with nuts.

To print choose your parts:

- 18mm Sensor With Chain

- 12mm Sensor With Chain

- 8mm Sensor With Chain

To use this please read below!

See my Thing https://www.thingiverse.com/thing:2783450 For how to setup Marlin firmware!

See https://www.thingiverse.com/thing:2784817 for how to install RAMPS on your printer.

Enable RAMPS boards, this is for the common ones like https://goo.gl/XW91zh [Amazon.com link] PLEASE pay attention and be sure to choose the correct code for your motherboards. See boards.h in the Skynet firmware for a list.

define MOTHERBOARD BOARD_RAMPS_14_EEB

Enable dual extruders:

define EXTRUDERS 2

Offsets for the extruders:

define HOTEND_OFFSET_X {0.0, -35.00}

define HOTEND_OFFSET_Y {0.0, 0.00}

For the probe it's :

define X_PROBE_OFFSET_FROM_EXTRUDER 17 // X offset: -left +right [of the nozzle]

define Y_PROBE_OFFSET_FROM_EXTRUDER -23 // Y offset: -front +behind [the nozzle]

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.5 // Z offset: -below +above [the nozzle Set this to your machine. I used a .5mm thick print put between the bed and probe with the nozzle touching the bed to start.]

And the travel limits are:

// Travel limits after homing (units are in mm)

define X_MAX_POS 240

define X_MIN_POS -10

define Y_MAX_POS 230

define Y_MIN_POS -13

define Z_MAX_POS 230

define Z_MIN_POS 0

You also must set

// Set the boundaries for probing (where the probe can reach).

define LEFT_PROBE_BED_POSITION 20

define RIGHT_PROBE_BED_POSITION 200

define BACK_PROBE_BED_POSITION 190

define FRONT_PROBE_BED_POSITION 20

I have made a guide in PDF form available here https://goo.gl/1s8jSR for setting the offsets. You will need a serial connection to your printer and I found using Octoprint is really easy.

Here's a crapCAD schematic of the optocoupler board I made to run the 12v probe completely isolated from the RAMPS board.

Enjoy! Like! Leave a comment! Thank you!

Update 10/16/2018 Added a little bit of play to the second extruder up and down to allow adjustment to meet the level of it's neighbor. This is done by loosening the clamp with the head resting on a level platform. Adjust both to level each other and tighten the clamp!

Now I admit I have not tested or printed this yet myself. I ordered parts to put dual heads back on the printer and will get this done in the next few days.

Let me know if anyone tries it!

/https://fbi.cults3d.com/uploaders/16051940/illustration-file/8d33d9e0-4c8e-4d76-a640-9e6b43340086/Lion_Mount_Cap_Front_18mm_Sensor_2.JPG)