Welcome to the 3DLS Lead Screw Drive Aluminum Frame 3D Printer by Morninglion Industries!

As seen on HACKADAY.com

You can find us on Discord! For tips, help and 3DLS specific stuff!

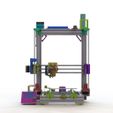

Here's a 4k render of the machine

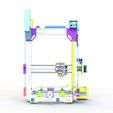

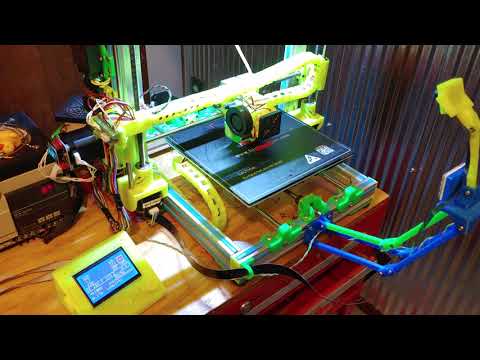

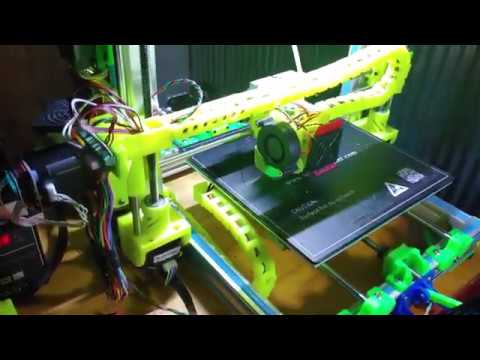

3DLS as of 7/28/2020

This is fully operational and printing now!

I have been rebuilding it with all the latest design parts and taking lots of pictures. Here's a gallery of all the pictures.

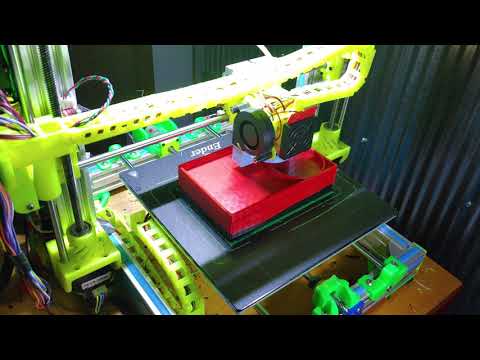

Video of it at 120mm/sec printing the back for my Rugged Raspberry Pi Tablet (https://www.thingiverse.com/thing:4245726)

Here's another Video printing at 150mm/sec outrunning my extruder the print didn't turn out well because the extruder could not keep up at these speeds. Follow up here and the timelapse of the failed print is here.

Current Status

Test print done, all per this build!

Full view

Full view

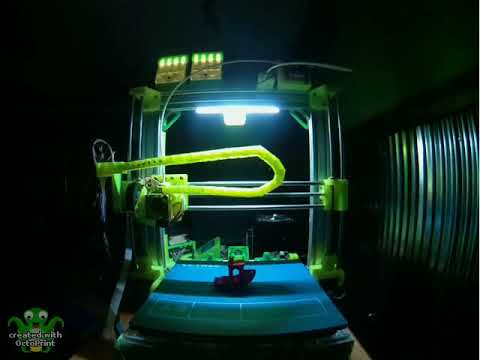

Full view

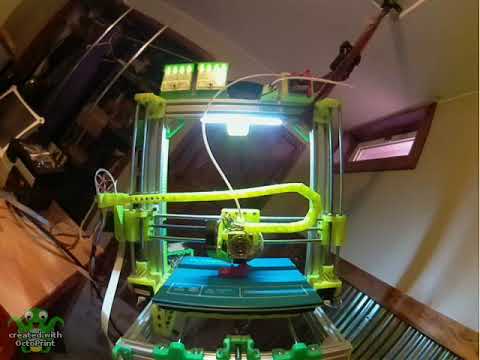

Full view

Full view

Then I strapped it up by one side…

I am writing the instructions now!

- Printing at 100mm/sec with accel set to 3000 on X and Y. Max speed is 300mm/sec.

- The precision is so good that the little compensations done by Prusa Slicer get printed out instead of compensating for anything.

- Machine is done. Marlin 2.0.3 included. Requires SKR 1.3 to meet speed requirements and SKR 1.4 Turbo is highly recommended.

- Machine runs best with TMC2208 on Z and Extruders, The closed loop controllers are required on X and Y for flawless operation.

Here's some pictures and links:

Slicer Settings, Prusa Slicer

It's now at 300 Accel X and Y with 100mm/sec top speed. There's still some over extrusion in the corners and some following of the infill. I am going to set infill/edge overlap to 0.

A video of it running for noise levels

The frame is based on Pheneeny's great AM8 (https://www.thingiverse.com/thing:2263216)

The extrusions used are the same as theirs but that's it.

Everything except the frame is my design.

You can retrofit most of this back onto an AM8 bit by bit however there's a lot of tweaks here.

Specs

- Prusa Type 3D Printer with No Belts!

- 235x235x235 Build Area but this is scalable to larger.

- Heated Bed, Uses Ender3 Bed

- CR-10, Chimera Dual or E3D Extruder, even dual extruder options! Can use any Lion Mount or Anet A8 type carriage.

- Smooth Rails

- Single or Dual Extruder

- SKR 1.4 Turbo 32bit Control @ 120MHZ

- LV8729 Drivers

- Closed Loop Control on X and Y axis

- Optional Full Web Control Via Octoprint Onboard

- Many More Options and Accessories!

Goals

- Ultimate precision at an obtainable budget

- High speed ability

- Compact overall size for Cartesian machine

- Off the shelf parts

- Easiest possible assembly

- No special tools or machining

- Ultimate reliability, thousands of hours between service

The Things That This Is Inspired From

In no particular order either…

- AM8 Z Motor Mount and Top Mounts with Bearings On Both Ends! (https://www.thingiverse.com/thing:4030339)

- AM8 Mod Y Rod Support wIth Full A8 Travel (https://www.thingiverse.com/thing:4028536)

- Anet AM8 Y Axis Lead Screw Drive System (https://www.thingiverse.com/thing:4008517)

- Anet A8 X Axis Lead Screw Drive System (https://www.thingiverse.com/thing:4002442)

- Creality CR-10 & Ender3 Type Extruder Mount for Anet A8 and Alike! (https://www.thingiverse.com/thing:3962768)

- AM8, Creality and Other 2020 Series Printer Rear or Side Spool Holder (https://www.thingiverse.com/thing:3934425)

- 2020 Series Extruder Mounting Clamp (https://www.thingiverse.com/thing:3934413)

- 8mm Frame or 2020 Bowden Inlet with Filament Sensor (https://www.thingiverse.com/thing:3934382)

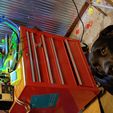

- SKR 1.3 Multi-Mount! Fits 92 or 80mm Fan (https://www.thingiverse.com/thing:3901774)

- 2020 Series Frame Raspberry Pi 2 & 3 Case Mount with 60mm Fan - Octoprint Ready! (https://www.thingiverse.com/thing:3540440)

- 2 Place 2040 Terminal Block (https://www.thingiverse.com/thing:3539475)

- 2020 Series Frame Raspberry Pi Camera Mount (https://www.thingiverse.com/thing:3539456)

- Lion Link Narrow Y axis chain for AM8 mod! (https://www.thingiverse.com/thing:3539350)

- Quad MOSFET 2020 Mount (https://www.thingiverse.com/thing:3538228)

- 2020 to 8mm Frame Adapter for Accessories! (https://www.thingiverse.com/thing:3538181)

- Ender3 Bed Mount for AM8 (https://www.thingiverse.com/thing:4161174)

These have been used as is or modified and assembled here into a standalone Cartesian 3D Printer with No Belts!

Full BOM

Items that are direct links are the parts the machine is designed to fit.

BOM for AM8 Conversion

With the conversion you use the A8 Y carriage so do not print the Ender3 bed carriage.

Firmware

I forked Marlin FW on Github, the latest firmware built and setup for the 3DLS is available on my Github page

Why the SKR 1.4 Turbo?

It's all about speed with lead screws. The speed a stepper can run at on a controller is proportional to the CPU speed. The CPU is what generates the pulses required to run the motor.

As an example a RAMPS with Arduino MEGA 2560 runs at 16 MHZ. This limits the step generation to about 10MHZ before the CPU gets bogged down and begins to miss steps, this is with a single stepper too, divide that across 4 and you can quickly run into issues. This is with Marlin FW.

Now on a board with a faster CPU like a SKR 1.4 Turbo at 120MHZ can run the steppers up to 100MHZ pretty easily. This means a much higher top speed without bogging the CPU down and causing issues. Also the 32bit board has much more RAM for running Marlin effectively.

Now there's still other considerations for speed and this machine will never be quiet. It's not meant to be fast or silent though you are trading those in for a much more precise control and quality in the print. As it sits I am limiting speeds to 100mm/sec at quad stepping in X and Y. Since the screw has to turn 4x faster for the same speed compared to the belt this runs it at the same steps per mm as the belt since it's 1/4th less steps.

This has no real effect on accuracy. It's all about elimination lash and the rubber band effect all belts have. I have run a tolerance test at 60mm/sec print speed with this machine and got .2mm pass on it. On my highly tuned Anet A8 I ran the same test at 40mm/sec and got .3mm.

There's more info on the SKR 1.4 Turbo here and this page has lots of information on stepper driving and speeds here.

/https://fbi.cults3d.com/uploaders/16051940/illustration-file/ad4e0363-547c-45ea-abcb-06d821c19a4e/3DLS_1_1.JPG)