I was not happy with the stock hotend of my anycubic kossel :

- heavy (n°1 problem from my point of view)

- airflow for heatsink cooling is somewhat constricted by design, thus requires high flow fan, thus noisy

- jhead v5 isn't melting the plastic fast enough and is limiting the overall speed of the printer

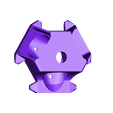

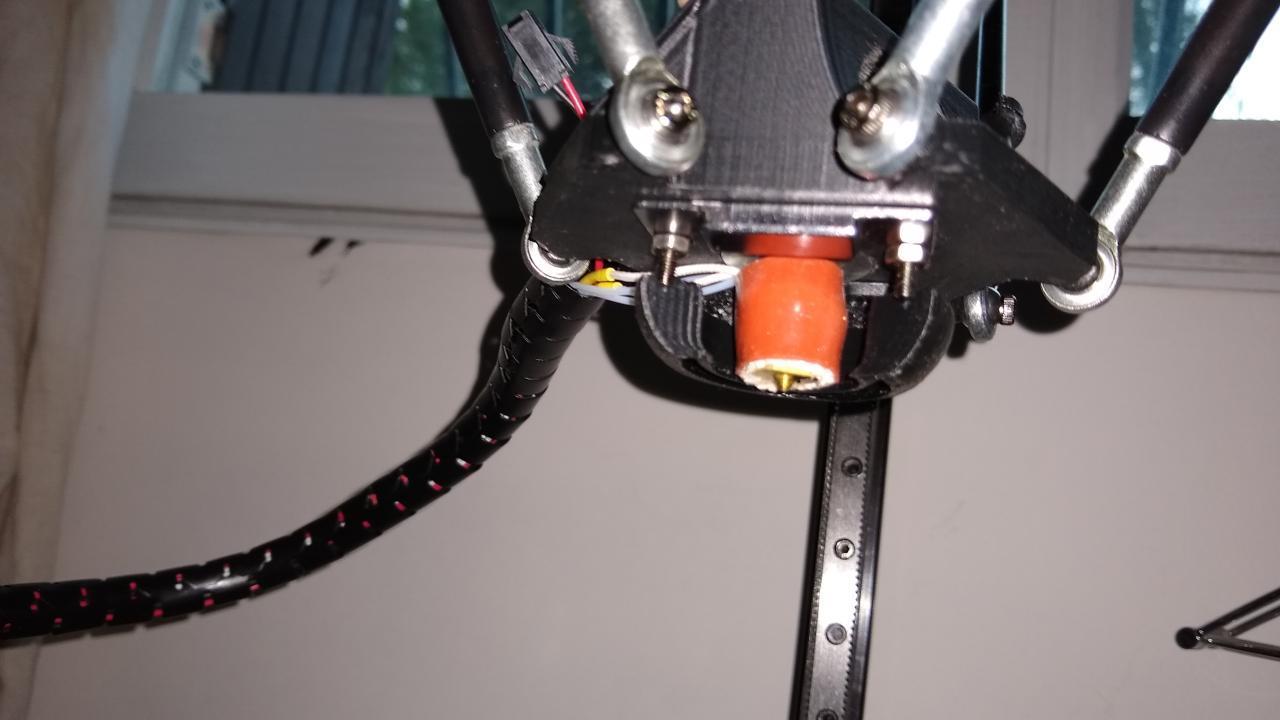

So I designed my own hotend with first criteria to make it as light as possible. For that I went for the TriangleLab e3d v6 heatsink clone, threaded version, associated with their ceramic heatblock. The result is that thing : 89g in full working order vs 196g for stock hotend (54% lighter). This means we can double the head speed for the same mechanical stress !

No functionalities are lost with this printhead :

- Full printing area is available with this hotend, it does not restrict it in any way.

- Stock Z-probe can be reused

- Independant cooling fan for parts is available as before

Ceramic heatblock does marvel during printing and the low weight eliminates almost all the ringing, a well known problem of this printer. Pictures of the calibration cube speak by themselves : All cubes have been printed with the same settings and the same PLA : 0.2mm layers H, 0.5 layer W, stock extruder ; 1 set of cube at 60mm/s 1 set at 120mm/s

Bill of Material :

- Threaded version of e3d v6 heatsink

- Heatbreak, bore version : You cannot reuse the stock one, it's not threaded to be mounted in the heatsink

- Ceramic heatblock, set2. This is not absolutly necessary, one can use stardard v6 heatblock or even volcano, but those heatblocks are heavier than this one

- 2x30mm fans. I struggled a lot to find small fans both silent (17 dB) and with a good enough flow (5 m³/h). I strongly advise NOT to take any fan with a smaller flow. dB is your choice ;-)

- 4x15mm M3 screws for mounting the fans

- 6x20mm M3 screws to attach the hotend to the rods. You can reuse the stock screws

- Magnetic plate for Z-probe can be reused from stock hotend

- 2x5mm M3 screws to attach the magnetic plate

- cables and connectors

Tools needed :

- A 3D printer ;-)

- sanding tool to remove support attachement inside of the hotend. A dremel will be helpfull but not necessary

- a small drill with 1.5, 2.5 and 3.5 drill bit

- an M3 tap will be helpfull but not necessary

Knowledge needed :

- How to modify marlin Configuration.h, compile and upgrade the printer firmware

- How to calibrate the printer (with marlin auto-calibration ;-) )

April 2019 evolution :

I mounted my effector with titanium full metal heatbreak from triangle lab and fed with cloned BMG extruder. This has been a huge upgrade. I'm now able to melt geeektech filament at 15mm³/s instead of 9mm³/s with original JHead, that's 67% faster. As melting filament was the bottleneck of the printer, I'm now able to print at 120mm/s, 0,2 layer height and 0.5 weight without underextruding. Thanks to the lightweight effector, the quality is very good even at that speed, better than the stock effector at 60mm/s :-)

Melting faster means more cooling needs. The quiet fan I indicated above was not sufficient after the upgrade, I had to use Alseye one for part cooling. It's noisier (30 dB, we can't have both) but the flow is now 11m³/h instead of 5, which is enough to cope with the higher filament flow. Look here (https://www.thingiverse.com/make:649231) for some test with it

** June 2019 evolution **

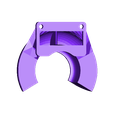

I've had problems with my fan duct while printing ABS : It got deformed by the heat after 10+ prints, so I designed the v2 in the help to minimise the problem : I added two reinforcement, two cooling holes and a smotther connection between mounting plate and round part. To help with overheating, I also printed it in white ABS instead of black and put some aluminium adhesive tape on the side in front of the heater.

Print in 0.1mm layer height, 100% infill and support/

The upgrade with the titanium heatbreak forced me to retune all the settings for PLA and ABS, so I uploaded my cura profile too. Beware retraction settings are for a BMG dual gear extruder. For stock extruder, stick with stock retraction speed.

I also replace all the screws by nilon screws to gain even more weight !

Happy upgrades !

/https://fbi.cults3d.com/uploaders/14753640/illustration-file/adfb7fba-2d40-4fc2-8499-28949d61d693/IMG_20190322_163510260.jpg)