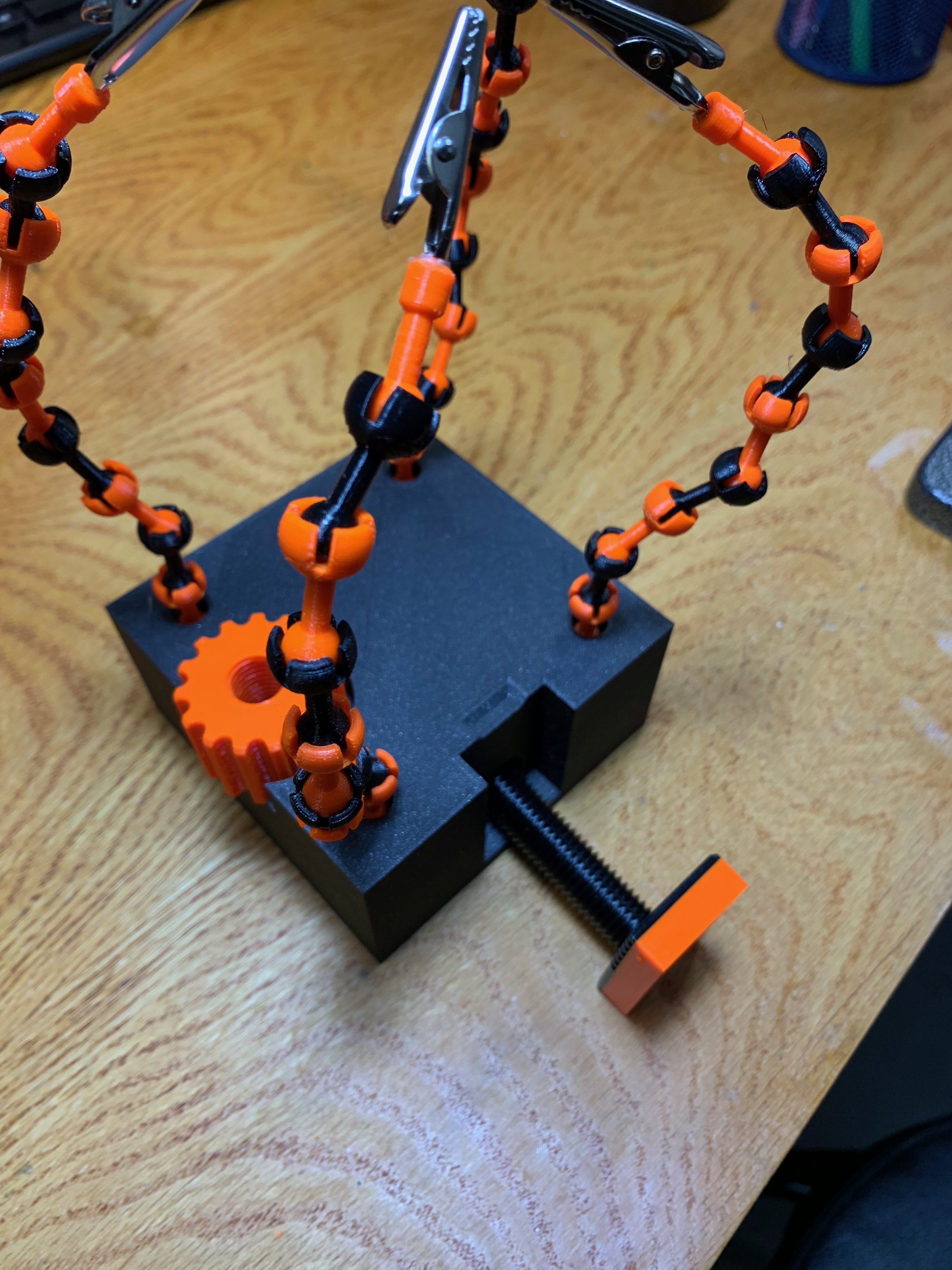

I based this design off a simple tool of similar function my Dad had (and still uses) while I was growing up. I wondering how I could design and make it with 3D Printing instead.

It is excellent for holding on to small electronic parts while soldering or doing any fine work that makes you wish you had a third hand. This design is fully 3D printed, minus the alligator clips and lead weights (optional).

When working with something heavier, or where I did not want the stand to move around I integrated a screw clamp. The threaded bar and clamp face clip inside the unit, when needed you pull it out and screw it in from the bottom. This jaw can camp to a max distance of around ~65mm.

Build instructions - All STL's are set for printing orientation. No supports needed.

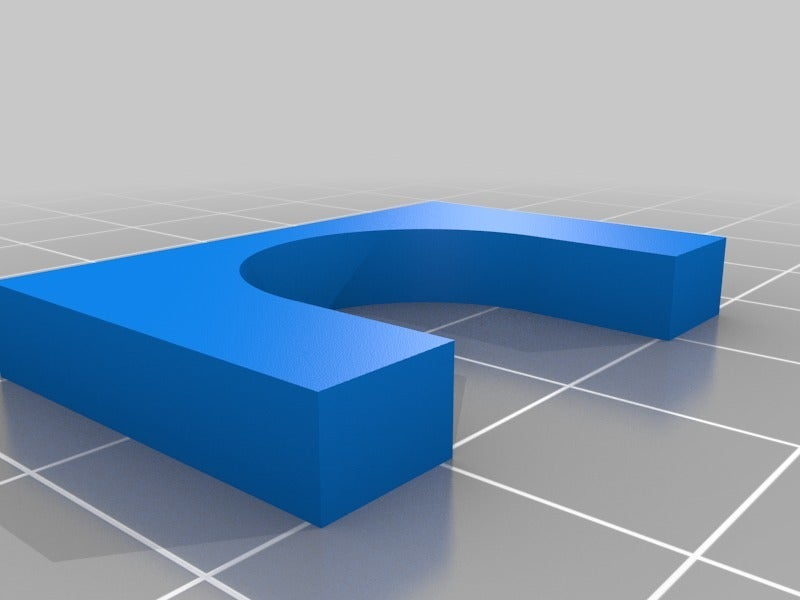

Base

The base is straight forward, can be made from PLA, PETG, or pretty much any material since it is not structural. I printed it with Prusament Galaxy Black at .2 layer, 10% infill, and 3 perimeter walls.

Lock Block

This is the block that holds the screw wheel in place, no material preference here.

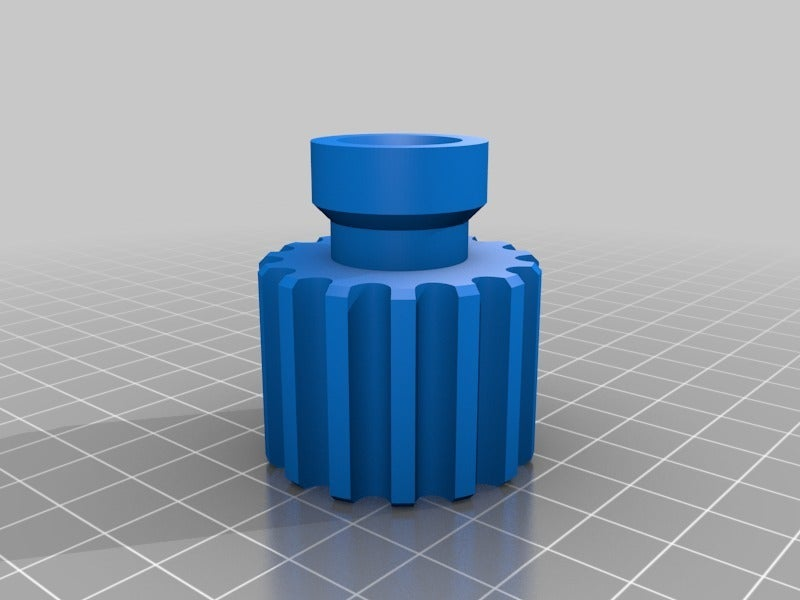

Wheel & Clamp

These are the two parts for the clamping mechanism. I only tested in PETG as I tend to do all threaded parts in that plastic type. You could probably get away with PLA since there are not serious loads. Go at least 50% on the infill with 3 perimeter layers. Note, I multicolored mine by doing a filament change during the print.

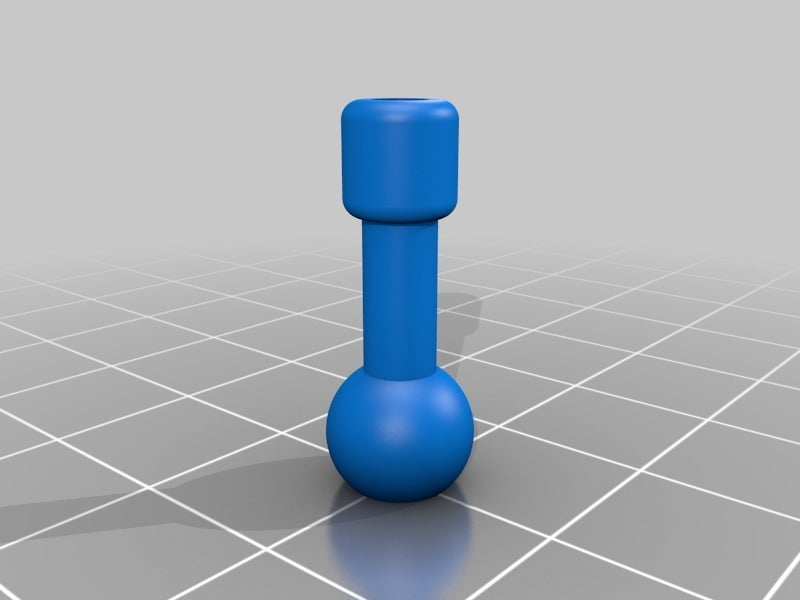

End Post & Post

You need 4 of the end posts, these are for the alligator clips. The regular posts, if you follow what I did, you need 32 of them. You can go more, you can go less, that is up to you.

I highly recommend PETG or something similar here, PLA was way too inflexible and brittle. I did quite a bit of prototyping here and found at minimum 80% infill with 3 perimeter walls the best. You could just go 100%, it won't add much time to the print job or material usage.

I found when testing with PLA I had to use brims. I stuck with it for PETG, but you could probably do without them. Make sure to clear the brim material at the base before assembling. UPDATE 02.07.19 - Brim it with PETG too, much more reliable.

Additional parts

Alligator Clips - https://www.amazon.com/gp/product/B01C50TIXC/ref=oh_aui_search_asin_title?ie=UTF8&psc=1

Lead Weights - There are 6 holes on the bottom, .45" in diameter. Don't laugh, I had some .45 caliber lead bullets for reloading laying around. Dropped those right in and capped the holes with epoxy. Worked great, so anything you can find to drop into those holes. It is optional, but since i had them around I decided to use them.

Assembly

Place the wheel into the base, slide the lock block under it. This is designed to be an extremely tight fit that will most likely require a small flat blade screw driver to push in. The way it is setup, you can put the gear up with a screwdriver from underneath to pop it if you ever need to get it out.

On the alligator clips linked, use pliers to close the ends. Place glue on the end and install into the end post.

Place glue on the bottom of one of the normal posts, install that into each hole on the top of the base.

Once glue is set, snap together the posts in the configuration and length of your choice.

Note on glues - I tested both epoxy and hot glue in the assembly and went with hot glue for both installing the alligator clips and posts to the base. This way if I need to replace a broken post, it is easy to remove. The hot glue is more than supportive enough for both applications.

Install clamp into base, or screw into bottom.

If you have questions, let me know!

Enjoy!

EDIT - 04.30.19 - I have added the Fusion 360 file for the arms for people with S3D who are having issues with the bodies. Feel free to modify however you wish.

/https://fbi.cults3d.com/uploaders/14802955/illustration-file/5bf1cb7b-4bfd-4ba1-a251-f8e7e385bc9a/IMG_0420.jpg)