Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

Desgined from grounds with idea of practical and looks.

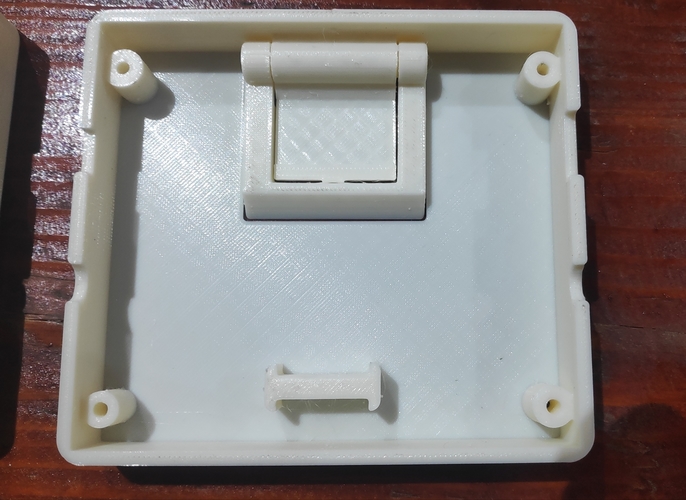

Built in print in place foldable legs that sit nicely in case when trx is not in use or it does not need them.

Column for encoder and pcb stress relief under it to prevent damage to pcb.

Holes for power connector screw access

Hole for built in key adjusted so when using that key top part of the case acts as stop for the key providing better keying expiriens and actualy making it easyer to use.

Knurled buttons, VFO more than AF, for easy manipulation even with glowes.

VFO Button does not use cut on top part of the case so trx has nice in line design

Inside columns for the screws holding two halfs have a bit mode material so metal inserts can be used or self taping screws.

Bottom side has buried holes so screw head does not stick out, it is made a bit larger so neodium 5mm magnets can be inserted if needed.

All corners are rounded giving it a nice slick look.

Printed in 0.16 for the case, 0.12 for the buttons to get better knurling details on the knobs 0.16 can can also be used there on prototypes i did not notice difference between 0.12 and 0.16, only placebo :)

Bottom part goes normal with only support need around flat part of foldable leg, and if your printer can not handle overhangs well on hole openings.

Top part is one object prints fliped so inside looks up and lcd side is inline with print bed. Support needed for part where controls are with 45* overhang. Depending on your setup you will get better or worse results for that part of the case. In case that i printed for my self, you can see that part totaly unprocessed, no sanding or anything else, directly from the print bed.

If properly setup after post processing of the print you can have nice smooth finish for that portion of the case.

Rest of the case details printed mine in cheap ivory colour PLA, 2 perimiters, 25% infill, 4 top 4 bottom layers.

Speed for walls 50, infill 70, solid infill 70, top solid infill 24, Small perimiters 24, Sliced with Prusa slicer printed on Ender 3

NOTE: You get bottom part file without any call sign marking.

All holes and openings are preset in design for horizontal expansion accounting for material contraction but since the material/printer/setup is imposible to predict for every usage case, you will need play with XY Expansion in your slicer, my suggestion print VFO knob first.

Comments