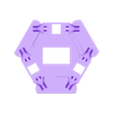

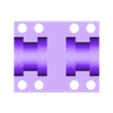

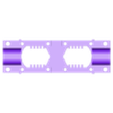

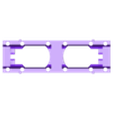

My 1830 universal effector for Anycubic Kossel Linear Plus

Semi universal.

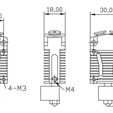

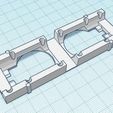

I am calling this my 1830 universal effector because that is the dimension of the main pocket. 18mm's X 30mm's. I have noticed that a lot of hot ends have this dimension, 18X30. Some will fit right into the pocket. Others will take an adapter piece or carrier to hold it in the 18X30 pocket.

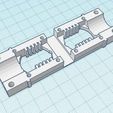

There are lots of tie points so you can pass wires through the holes, or use them as anchor points for wire ties. But there is no room for wire connectors, so I left the ends of my wires bare so they can pass through the loops. I used some small wire terminals. I soldered wires from the printer to the terminals. Then I can screw in the wires from each hot end. Heater 1 and 2, sensor 1 and 2, LED's, hot end fan, layer fan.

I embedded 3mm brass nut inserts into the back of the effector pocket to mount the carriers or hot ends into the pocket. You will need (2) each 3X30mm screws to secure the hot end or carrier in the pocket. I also embedded 3mm brass nut inserts into the square holes on the sides for the connecting rods. If you use a 3X25mm screw for the rod ends it will reach the insert with the rod end installed. The nut pockets are still there and are reachable with a 20mm screw if you prefer nuts over inserts.

There is a small brim around the connecting rod mounting points to keep them stable and flat during the print. Trim away post print.

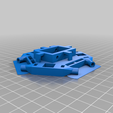

I started with thing 2422030 and remixed it into my effector for an E3D V6 hot end, 2640121.

The original effector is 6mm's thick, mine is 7. The rod end mounts are 52 mm's wide. So are my carriages. This way I don't need the spacers.

This worked well for me for years, then I got the itch for dual extruders. I designed an effector that will hold (2) E3D V6 hot ends, but it is pretty bulky. The two nozzles are 24mm's apart. I made one, but never installed it. I was never 100% happy with my fan designs.

Then I discovered 2 in 1 out hot ends. There are a lot of them that measure 18mm's X 30mm's. I have seen them described as MK8, J head, Cyclops, and Chimera. I believe Cyclops is 2 in 1 out and Chimera is 2 in 2 out. I wanted to experiment with different hot ends so instead of designing a different effector for each one, I decided to design a semi universal effector, then design different carriers or adapters for the different hot ends.

3D Printer V6 Cyclops Chimera 2 in 1 out + 2 in 2 out Printhead Extruder

This hot end will fit into the effector 18X30 pocket. Secure it with (2) 3X30mm screws. This hot end has the angled top. I placed a 30mm fan in the back blowing in to an open fan shroud. I placed a 30mm fan in front, also blowing in, onto the fins of the hot end.

Startisan 2 in 1 out hot end. My hot end says Startisan across the top, and I have seen these also with Big Tree Tech. It will fit into the effector, upside down. Kind of a PITA but remove the effector from your printer the re-mount it upside down. Slip the Startisan hot end in from the bottom and secure it with (2) 3X30mm screws.

This hot end has to fit into the effector upside down because of their hole placements and dimensions. It will fit into the effector right side up, but then there is no room to mount the fans.

I placed a 30mm fan in the back blowing in to a split fan shroud. I placed a 30mm fan in front, also blowing in, onto the fins of the hot end.

This hot end is the reason that I added the 3mm brass nut inserts to the connecting rod mounts in the effector. It is kind of hard to hold a nut in the pocket upside down while trying to start a screw.

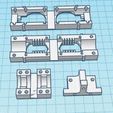

I have a holder or carrier for:

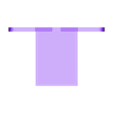

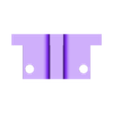

J Head 18X30 - 2 in 1 or 2 out

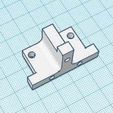

This hot end is short. It measures 18X30, and 30mm's tall. So it needs an adapter to fit into the 18X30 pocket. It also has to be suspended down a little bit, so the 2 mounting screws up top will clear the tube fittings in the hot end, and to provide clearance for 30mm fans. .

Screw the tee shaped adapter into the top of the hot end using (3) 3X25mm screws. Then secure the adapter into the effector using (2) 3X30mm screws.

I placed a 30mm fan in the back blowing in to a closed fan shroud. I placed a 30mm fan in front, also blowing in, onto the fins of the hot end.

MK8 12 X 20 - 1 in 1 out

This hot end is really tiny. 12X20X27mm's tall. I placed a 30mm fan in the back that is blowing air in to a split fan shroud. I placed another fan in front, backwards, sucking air out. Sandwich it all together with (4) 3X50mm screws.

MK8 16 X 22 - 2 in 1 out

This hot end barley fit. I made an adapter for it, but I also had to modify the hot end a little bit. There is a wide circle part on top that I removed, then sanded down the edge to make it flat and I made it 16mm's wide. I also had to shave the sides slightly where the screw passes by. I placed a 30mm fan in the back that is blowing air in to a split fan shroud. I placed another fan in front, backwards, sucking air out. Sandwich it all together with (4) 3X50mm screws.

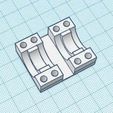

E3D V6. Slip the 2 half blocks around the collar of the hot end and insert into the 18X30 pocket from below and secure with (2) 3X30mm screws. There are 2 sets of mounting holes for added confusion. No good reason for the duplicate holes. I just like symmetry for some reason. Use your favorite E3D V6 fan shroud.

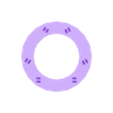

LED holders.

I use these LED strips that have 2835 led's, 600 LED's per meter. One section of 3 LED's is 25X8mm's. I soldered wires to the end and peeled the backing paper off, and added a couple of drops of super glue and stuck them to the holders. I mount them using the screws that hold in the fans.

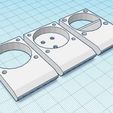

Fan shrouds (Layer fan shrouds)

There are 3, open, closed and split.

With all three designs there is a very thin spot at the top of each fan shroud. It can be a little hard to print. I have found that printing 2 fan shrouds facing thin spot to thin spot with a little brim between them really helps.

The open fan shroud is used with the hot end that measures 18X30 and has the angled top.

The closed fan shroud is used with the hot end that measures 18X30X30mm's tall with a flat top. It has 3 mounting holes for the hot end. I embedded (4) 3mm brass inserts for the fan.

The split fan shroud is used with everything else. It will divert about a third of the air from the hot end to the layer. That doesn't sound like much but I have given it the bic lighter test and it works!

The stl file list:

1830 uni effector

MK8 12X20

MK8 16X22

MK8 18X30

E3D V6

30mm closed fan shroud

30mm open fan shroud

30mm split fan shroud

LED holder

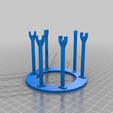

stand

The hardware list:

3mm brass inserts 3mm threads, 3mm's long, 4mm's wide

3X20mm for the connecting rods using nuts

3X25mm for the connecting rods using inserts

3X30mm for the 18X30 pocket

3X50mm to sandwich fans, shroud, and carrier

I bought a couple of hardware assortment sets on Amazon. I found that it really helps to have these different sizes available during a build. I bought 3mm socket head cap screws, assortment from 6mm to 20mm long, and 3mm nuts. And 3mm socket head cap screws assortment from 30mm to 50mm long, and nuts. I bought some 25mm's long screws locally, So I have a range from 6mm's to 50mm's, in 3mm socket heads screws. Very handy to have.

Printed in ABS .2 layer 50% infill

/https://fbi.cults3d.com/uploaders/16159417/illustration-file/cf1d60ed-4246-4061-8f07-f52d68750a47/1830_effector.jpg)