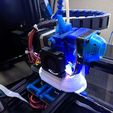

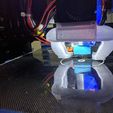

E3DV6, 3:1 Geared Direct Drive Extruder, Bullseye Mount

This mount combines an E3D_V6 hotend and a Printed Titan - "Pitan" https://www.thingiverse.com/thing:2728600 geared extruder on a carriage with the same mounting points as the original bullseye cooling duct https://www.thingiverse.com/thing:2759439

Like the SpeedDrive, it places the stepper motor as close as possible to the movement axis to reduce the ghosting that happens from bounce in many direct drive configurations. This also uses a 3:1 gear ratio extruder, which ensures that the extruder has the power to push filament, even if it's a weak flat pancake.

When I made the upgrade to linear advance and my print speeds went up to 150mm/s, the gears on my Pitan started having issues with cracking. I designed a small gear with a cuff with an M3 retainer nut and made a thicker mount plate for it to fix that problem, which is available in this package. The M5 bolt fitting wasn't snug enough for my purposes either, and my changes to the original are included in Gear2-Tight.

The Bullseye part cooler provides some of the best part cooling I've encountered and uses the default hardware that comes with Creality printers.

I couldn't find a mount that includes all these parts so I designed this one.

Update 6/7/2020

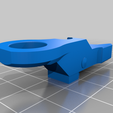

I added a new Pitan extruder arm I designed for a C (R188) size wide concave yoyo bearing. This makes the Pitan better at flexible (TPE, Ninjaflex) filament extrusion on the standard extruder gear. It doesn't work with grooved extruders like the hobgoblin. If you're using a flat extruder gear, the concave bearing keeps the flexible filament from slipping to either side.

What To Make

Pitan

- First off, you're going to need a Pitan Extruder (https://www.thingiverse.com/thing:2728600)

- Instead of the normal long M3 bolts, you're going to need 3X 45mm M3 bolts.

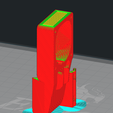

- For the gears, use the two gears that are provided here for the reinforced drive gear and a wiggle-free M5 secondary drive.

- The central drive bolt on the Pitan should also be 25mm, so there's no bolt sticking out the non gear side, as in the pictures.

- The filament loader helper goes in the lid and is supposed to keep pressure on the PTFE guide tube.

- You can use the standard extruder gear your printer came with.

Bullseye Part Cooling Duct

- Print a bullseye cooling duct (https://www.thingiverse.com/thing:2759439) You just need the duct.

Assembly

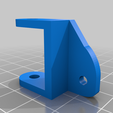

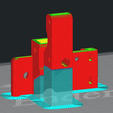

- On the Mount, find the slot for the M3 nut that holds the part cooler and slide a nut into it. Slide a nut into the two edge mounts for accessories, those will hold the Hotend Cooler assembly.

- Place the Pitan, with the hotend clamped in, on the mount, on the right side of the stepper mount, run 3 X 45mm screws through the Pitan into the mount.

- With the Hotend Cooler, slide a M3 nut into the slot under the fan mount. Screw the hotend fan onto the Hotend Cooler with M3 12 bolts with the air blowing in (usually that's the sticker facing inside). Screw down the Hotend cooler to the accessory mount.

- Connect the Bullseye Duct via the two m3 bolts installed in the cooler and the mount.

- Push the Gear 1 for the Pitan onto the stepper, with the cuff facing towards the stepper and screw a 3mm M3 flat profile bolt in the cuff.

- Screw down the stepper via the three 45mm M3 bolts.

Additional Configuration

You're probably going to need to update your firmware to use this mod. The new extruder runs in the opposite directionof the stock extruder. The procedure for reversing the extruder motor will vary according to the firmware you're running. You can also flip the wires on the stepper connectors to reverse the stepper direction.

You're also going to have to set new step /mm values for your extruder. It's usually very close to 320 steps/mm if you use the OEM extruder.

If you're using the original stepper instead of a pancake stepper, you should also print the clearance gantry. Two versions of the x gantry cover are included. The endstop version is the one to print if you don't have stallguard based homing.

PRINTING TIPS

I recommend printing the mount with supports 60% and a brim to guarantee adhesion.

The hotend cooler can print without supports provided your printer can bridge 15mm gaps.

I printed it all in PETG, but PLA should work just as well.

/https://fbi.cults3d.com/uploaders/16333273/illustration-file/5fef83ea-0cc3-4115-9453-61e54eb1042d/IMG_20200527_100926.jpg)