At today this is only a proof of concept

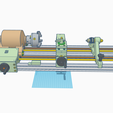

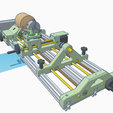

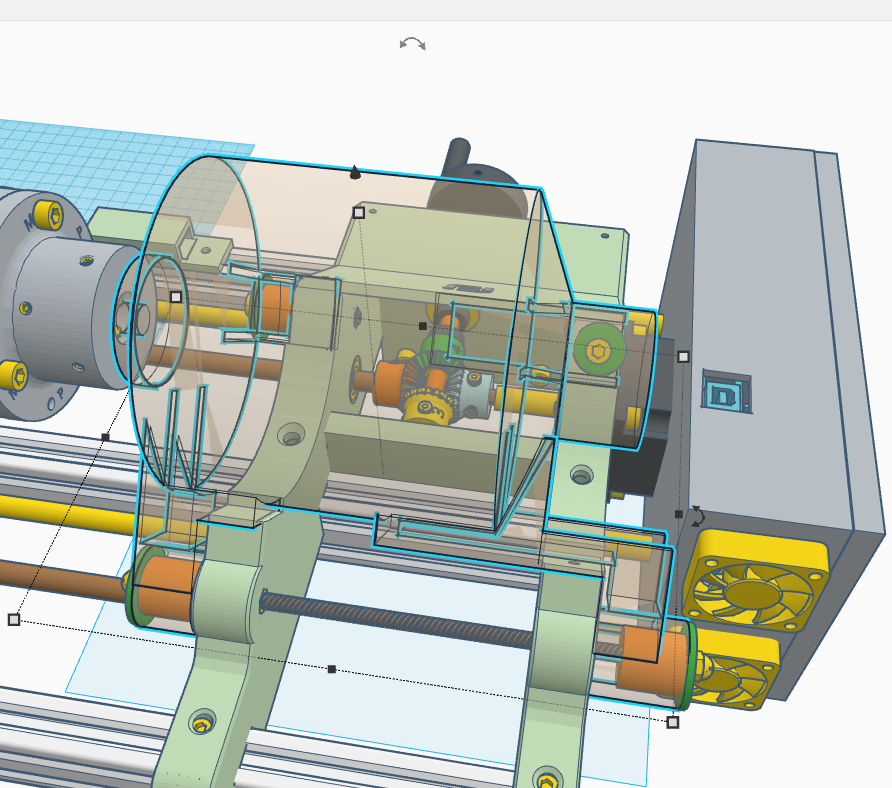

Well, this is V5 version of my lathe.

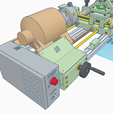

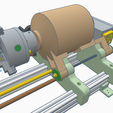

My goal was to make use of that easy to find washing machines motor; at today they're all BLDC (Brush Less Direct Current), very similar as concept to the stepper motor we're used to,

They can be driven by PWM generated from an MCU and boosted to proper voltage and current by 3 drivers (like IR2110) and an IGBT (Mosfet array).

The motor I use is an Ignis WM (Nideco motor) and needs 195VDC at 310Hz for max power and speed, but it can be driven with a lower frequency (less speed and without almost any loss of power); I opted for an VFD 220V 0-400Hz 1,5KW and 50Hz seems to be good choice.

Furthermore it features wonderful bearings, engineered for big radial charge, perfectly balanced rotor and, last but not least, a very quit operation.

Among downloaded files you'll find a text file with the link to download the whole project.

It features:

- moved the main carriage sliding wheel to a more intuitive position

- optional CNC via Arduino Mega and RAMPS; if you don't want it just omit related items

- continuously variable speed via a cheap BLDC controller

- rotating tools turret 0-360° at 45° steps

- tailstock carriage sliding via T8 lead screw, manual action

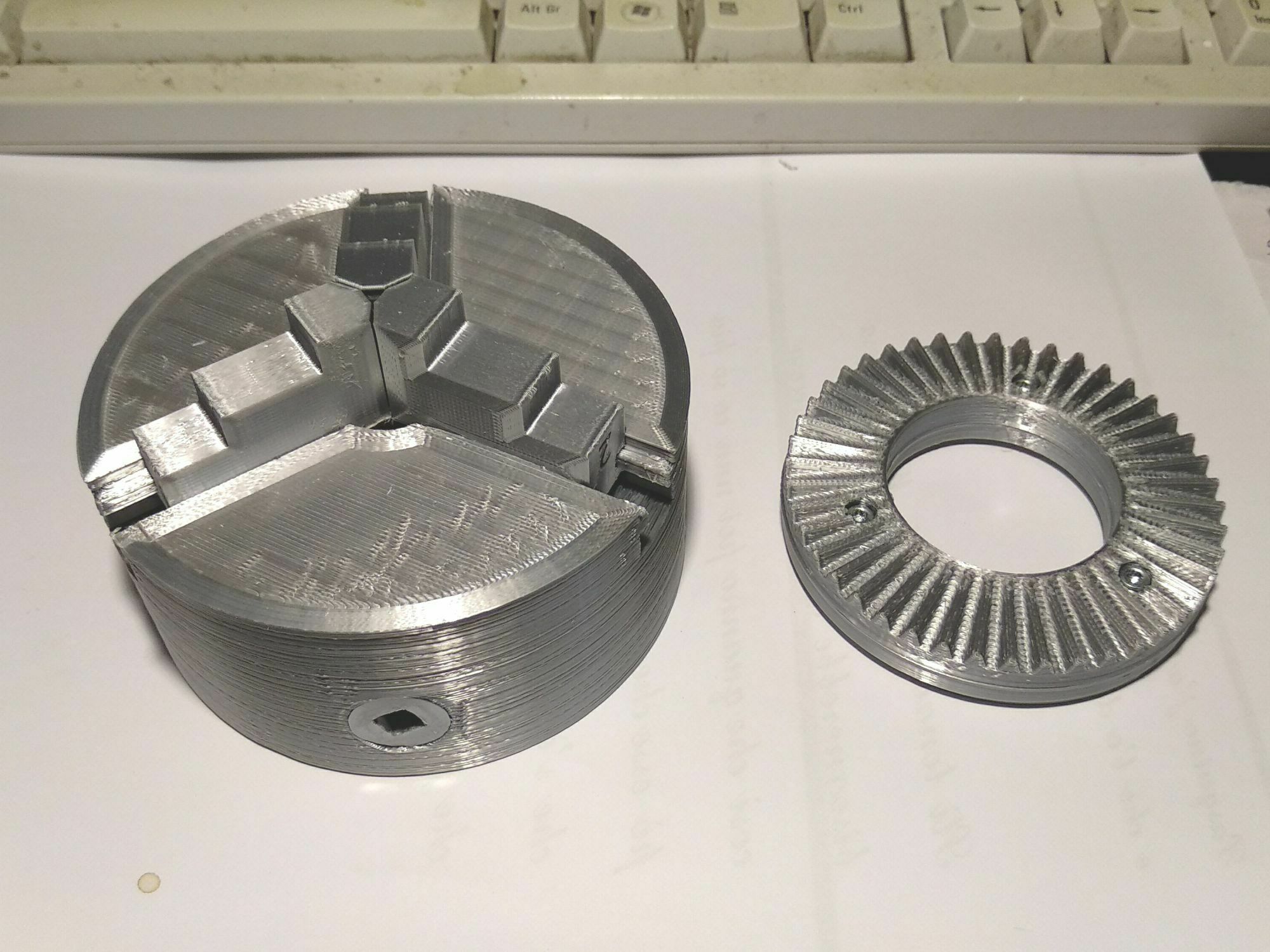

- can accomodate every printed 80mm chuck or optional metal one from China

- supports width reduced to 20mm, no one can spend 39 hours to print just one support!

I hope you like it...

Instructions

Chuck:

- Insert, while threading, the chuck adapter eight grubs to motor axis, then tight a bit more to let a mark on the axes

- Disassemble all and with a 6mm drill bit make a little cone to each mark on the bolt, to accomodate the grub points

- Reinsert the adapter and tight well the grubs

- Grease well all chuck moving items

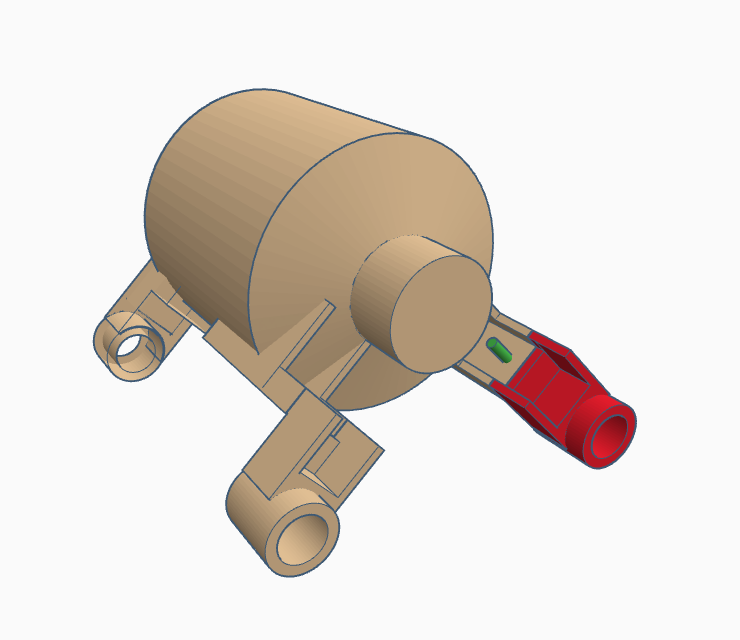

Motor:

- Cut away the part marked in red in the above picture and drill one 5mm hole to the remaining part (see picture above)

- Put in place the three motor_support_adapter

- Put in place the motor

- Insert and tight the threaded bar, washers and nuts

- Insert, while threading, the washer and 5mm bolt

CNC / Manual operation:

Switching between modes is very simple, just a 4 poles switch ON-OFF.

In short, if there's no wired stepper to a driver, it doesn't take it badly, so when you want to work manually you've only to cut off the steppers.

SWITCH BETWEEN MAN-AUTO ONLY WITHOUT POWER APPLIED

or you'll fire up the drivers!

BOM

Electronics:

- n. 1 washing machine BLDC motor

- n. 1 Arduino Mega 2560 board

- n. 1 RAMPS 1.4 board

- n. 1 12 pins ON-ON switch

- n. 2 Nema23 steppers

- n. 2 40mm fan 12VDC

- n. 2 hall proximity sensors

- n. 1 10/100K linear potentiometer

- n. 1 knob

Body:

- n. 3 profiles 2040 800mm (or at your choice)

- n. 2 T8-2 screw 800mm (or any length)

- n. 1 T8-2 screw 240mm

- n. 2 8x680mm rods

- n. 2 8x240mm rods

- n. 1 8x180mm rod

- n. 1 6x40mm rod

Bearings:

- n. 12 bearings 608Z

- n. 3 bearings F608Z

- n. 1 bearings F6000Z

- n. 10 bearings LM8UU

Miscellaneous:

- n. 1 M5x40x3mm washers

- n. 3 M5x30x2mm washers

- n. 1 M5x15x2mm washers

- n. 2 M5x25x2mm washers

- n. 2 M5 blind nuts

- n. 1 drill chuck

- n. 1 drag chain 15x10mm

- n. 7 M8 lock ring

- n. 6 T8 nuts

- n. 1 flexible coupler 6.35x8mm

- n. 4 10x10x1.5mm springs

- M5 flat head screws

- M5 nuts

- 6mm profile nuts

- M5 grubs

- n. 2 8x3mm neodymium magnets

- lythium grease

- sewing machine or silicone oil

Optionals:

- n. 1 80mm chuck

- n. 1 cheap VDF 1.5KW 3 phase controller

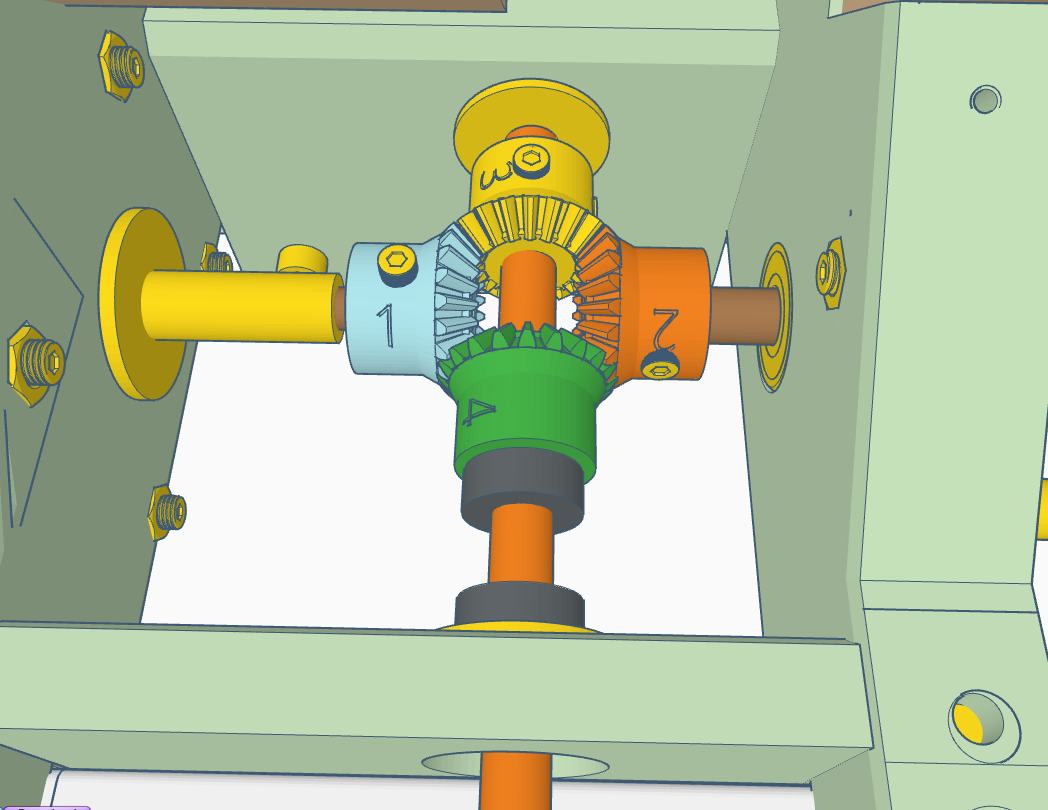

- n. 1 Bevel gear 1.5 Modulus 20 teeth 6.35mm bore (optional)

- n. 3 Bevel gears 1.5 Modulus 20 teeth 8mm bore (optional)

- n. 1 center point

/https://fbi.cults3d.com/uploaders/15451373/illustration-file/ec74b595-621a-4740-a31c-4054f3b7ea27/1.png)