Here I go, again...

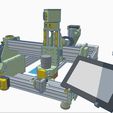

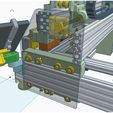

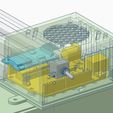

This is a little bit improved V9 version, but it implied several remixes and changes, so I had to publish it as new project.

It's my latest version of Ooznest OX CNC Machine (https://www.thingiverse.com/thing:1684109), well designed, very strong and well documented (I advice to go there and here and read all carefully).

You can configurate it as per your need: motor type, blower, vacuum, laser and so on.

UPDATES:

2022-10-02

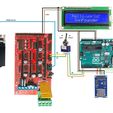

Added an LCD2004, an SD reader, so you don't need anymore PC and USB cable.

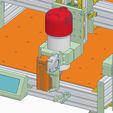

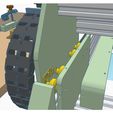

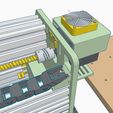

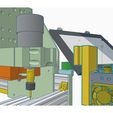

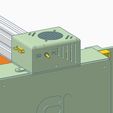

Added Laser support and a blower too, having read this is the best solution to avoid black baffles on wood; not too much effective, but...

This upgrade uses an Arduino Uno to communicate with Arduino Mega.

It took a few of time to realize a simple and versatile software; I gogled around but I found only few codes, working and not working, but no one satisfied my needs.

So, a function there, a function here, I realized my own code, simple and effective.

As you can see, after job ended it resets and asks again for SD; this way you don't need tu shut down and restart.

There's anyway a little limit: on SD card must reside just one file and no directories; no one is perfect, sorry!

For laser I designed a blower too, having read this is the best solution to avoid black baffles on wood; not too much effective, but...

Al necessary items are pre-fixed with "LCD_".

Arduino code and modified library GRBL are into CODESENDER.ZIP.

Engraving video at https://dai.ly/kKOsLwtnSf1pRaySUpY

Remixes:

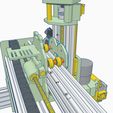

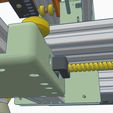

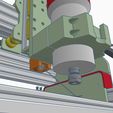

- X axis moved on up to avoid collisions, dust and so on

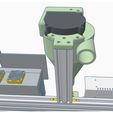

- Z operative range now is 90mm

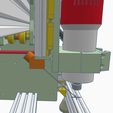

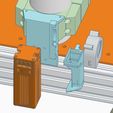

- improved Y axis carriage

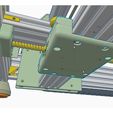

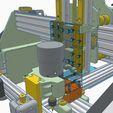

- Arduino Mega + RAMPS are now used, due to lack on spare pins on Uno + CNC shield

- added spindle motor variable speed

- added CW-CCW capability (optional, see below) to perform automatic tool changing

- a lightweight Z carriage allowing a 90mm Z height; who is interested to can find it here

Several options are available:

- Cyclone dust collector, see uploaded CYCLONE.ZIP

- a little blower, see uploaded BLOWER.ZIP

- a very simple modular ATC

- an 8-10" tablet support, see here

- support for Makita mill Chinese clone, see MAKITA_SUPPORT.ZIP

- support for cross-hair laser pointer

Included .STEP of all items, see STEP.ZIP.

Instructions

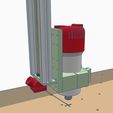

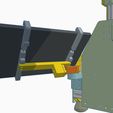

Y Axis

(see picture above)

- at exactly the center of 2060x454mm cut away an 25x20mm (HxV) portion of material

- at exactly the center of 2060x437mm drill an 10mm hole

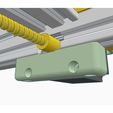

Feet

Glue circular shape 10mm thick rubber pads into feet bottom.

INSTRUCTIONS LCD+SD

When you've to access Uno or Mega to flash firmware, you must put the switch PC/SD in PC position; this way the RX/TX lines are interrupted. This is necessary because USB and RX/TX are not to be used at same time.

Apply same above when using CNC from PC via USB.

Laser:

When using a Laser, make connections like in second schematic picture.

PWM is from D6 pin in RAMPS; it was necessary because of 5V TTL needed by laser.

In defaults.h/DEFAULTS_RAMPS_BOARD set

#define

DEFAULT_LASER_MODE 1 // true

CNC:

In defaults.h/DEFAULTS_RAMPS_BOARD set

#define

DEFAULT_LASER_MODE 0 // false

Software

I'd advise to use Gnea GRBL for compatibility with almost all CAM software around Read it carefully

- decompress GRBL-MEGA_5X_1L.ZIP somewhere and copy the resulting grbl_Mega directory into your Arduino IDE libraries directory

- run Arduino IDE and set board tyo Arduino Mega

- load \libraries\grbl_Uno\examples\grblUpload

- flash to board

To manage my CNC I use the friendly UniversalGcodeSender (UGS) .

I uploaded my own GRBL version, ready to be used; you can modify everything there

The optional 5mW cross-hair laser pointer may be dangerous for your eyes.

Take all precautions to avoid hazards

BOM

2020:

- n. 2 x 200mm

2040:

- n. 1 x 437mm

- n. 2 x 500mm

- n. 1 x 710mm

2060:

- n. 1 x 437mm

- n. 1 x 454mm

- n. 2 x 500mm

2080:

- n. 2 x 750mm

wheels

- n. 22 Delrin wheels 24mm

- n. 30 spacers M5x6mm

- n. 10 eccentric spacers M5

- washers M5x1mm

lead screws

- n. 1 T8 lead screw 710mm

- n. 1 T8 lead screw 465mm

- n. 1 T8 lead screw 220mm

- n. 3 T8 lead screw nuts

- n. 1 608ZZ bearing

- n. 1 688RS bearing

- n. 2 625-2RS bearing

- n. 2 608ZZ bearing

- n. 2 8mm lock collar

- n. 3 Openbuilds anti-backlash nuts

other

- n. 1 Arduino Mega + RAMPS 1.4

- n. 1 Dual H-Brifge 40A

- n. 1 power supply 12/24VDC 30A

- n. 3 Nema23

- n. 1 spindle motor OD 52mm, 200W or more, 12-24VDC

- n. 1 Chuck ER11 8mm

- n. 1 spindle collets set 13 pcs

- n. 1 Neato fan (refurbished) Aliexpress, optional (see BCB1012UH.PDF included)

- n. 1 5VDC DPDT relay module for reversing CW-CCW (optional)

- n. 5 40mm fans bearing

- n. 1 radial blower 50mm (optional)

- n. 2 Transmission Chains 20 x 15mm or bigger

- n. 1 wood workplane 706x430x20mm

- n. 3 spacers M5x35mm

- n. 6 spacers M5x23mm

- n. 1 coupler 6.35mm->8mm

- n. 2 flexible coupler 6.35mm->8mm

- n. 3 Hall effect sensors for endstops (optional)

- n. 3 8x3mm round Neodimium magnets, if used Hall sensors

- screws flat head 3mm, 4mm, 5mm, nuts, as needed

- lithium grease

- silicone oil or sewing machine oil

- Optional Laser pointer

Credits

Ooznest (https://www.thingiverse.com/thing:1684109), of course...

NitroXpress (https://www.thingiverse.com/thing:973505/files) for its nema23 cooler cover

mgx (https://www.thingiverse.com/thing:124551) for its Scad customizable cyclone separator

/https://fbi.cults3d.com/uploaders/15451373/illustration-file/922c4507-80af-404c-8c68-1181d0829c37/1.jpg)