I use the magnifying glass of the phone on the x, y axis to see the deviation of the tool in 2 reference holes when turning the double sided PCB. Preferable the jaw on "y" for perpendicularity, intervening under the board is more difficult. If you have, any techniques or profiles to print about double sided PCB turning, try to notify me, Thanks

small negligence

- the wing nut of the original holder could touch the chuck.

To correct foam thickness 1cm, common??? remount the trapezoidal profile.

=>March 15 corrected the height of the trapezoid.

=> not corrected, say, not checked the wing nut if it touches

the chuck

- the end of the chuck could touch the jaw, especially when punching/drilling.

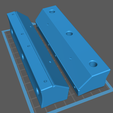

To be corrected at least 4 mm further (further from PCB) the holes of the jaw. See support profile end PCB side.

The height is a fear I have, in relation to the risk of deformation, twisting. *** also use bolts provided with 3018pro

=> March 15, just shifted the drilling to the outside and made

a slope at the same time, the curved profile, 2 profiles, one

is for 3D printing as the drain holes of the

resin. avoids the phenomenon of aspiration, I do not know if its

will take off under the current profile.

The 2nd profile under the jaw is to promote the support side

PCB.

=> IMPORTANT, it is possible that it is preferable that the chuck

tap the holder to avoid tool breakage, when

errors on manual movement mm in CM and paff!!!

=> March 15, put 6.2mm, but it also passes in lapping

a little to 6.1mm in diameter

-More annoying in resin printing the resin drain holes are slightly too small at 2mm, let's say it passes, better 3-4mm.

=> March 15 put 2.5mm it seems.

-Put the file under several files, not a kit after!!!

To tilt the parts during printing, Like rail profiles, to gain speed or force resistance (printing layer. The jaw has a difficult profile at the beginning of printing (better inclined).

-*** If the chuck touches the jaw, there is the advantage of not breaking the tool. Not easy, if you get the travel distance coefficient wrong.

Initial text before above:

A small kit without being thoughtful, with original screw wing nut, a little too tight on the screw diameter.

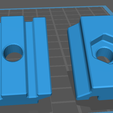

The jaw is high 25 mm hollowed out with ChituBox, 4 or 4.5mm wall.

I printed without support without tilt on "Elegoo Mars pro 2", can be wasteful if its comes off at the beginning of printing (risky),

The 1.5-1.6mm thick PCB fits well in the trapezoidal profile (1x2, 1mm deep it seems), previously a 2mm deep version, so gained a little there.

Jaw length 113mm (I use PCBs of 10-11cm x 7 ). Maybe provide a foam under the PCB and it is possible that the height of the trapezoidal profile is not adapted to the current thickness of foam. Finally I prefer to support the slight deformation when the tool passes by a foam.

I am well interested, in methods facilitating the turning of double-sided PCBs, in case you have that.

I've searched and not found a single similar kit, here you go

==============

I take back the correction intention later, in a few days or you do it yourself.

Make a work table edge profile on X (front and back), at least the profile. I don't know what it would be good for, except off PCB in additional fastener.

A lamp, led would be useful

March 14, the jaw still not good, the table profile is rather good just the 6.1mm diameter that sticks a little, 10mm screw head/impression (10.4mm it seems).

March 28, 2021, I printed the jaw, which looks good. Yes, one of the jaws should stay fixed if the perpendicular is perfect. Not thought about anything practical and quick, except note the gap from the edge of the table to the 2 ends of the jaw.

The wing nut must absolutely be in the y axis and the chuck will not touch it. Add a chuck axis stop (anti-tool breakage).

Yes of course the limit switches are useless if they are not positionable at convenience (ends of the machine and not in relation to the jaw/obstacle). The idea of removable limit switches is a very good idea.

Print the part as it is, presents a not so good print start, the arc is too soft and collapses during hydraulic forces (resin), some support or take the risk.

Good maintenance of the pcb, but it seems to me that the worm clearance would deserve to be a little more reduced, I have a doubt of tenths of mm of errors/game.

A led lamp?

Double sided pcb turnaround aid?

/https://fbi.cults3d.com/uploaders/14318796/illustration-file/4d6750d4-fcb7-4ac0-9917-a19a51ecb133/bride_rail.png)