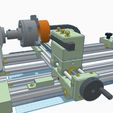

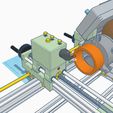

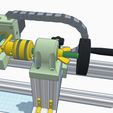

Well, this is V6 version of my lathe.

My goal this time was to design something easy to build, cheap enough and versatile.

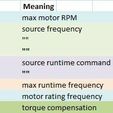

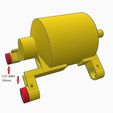

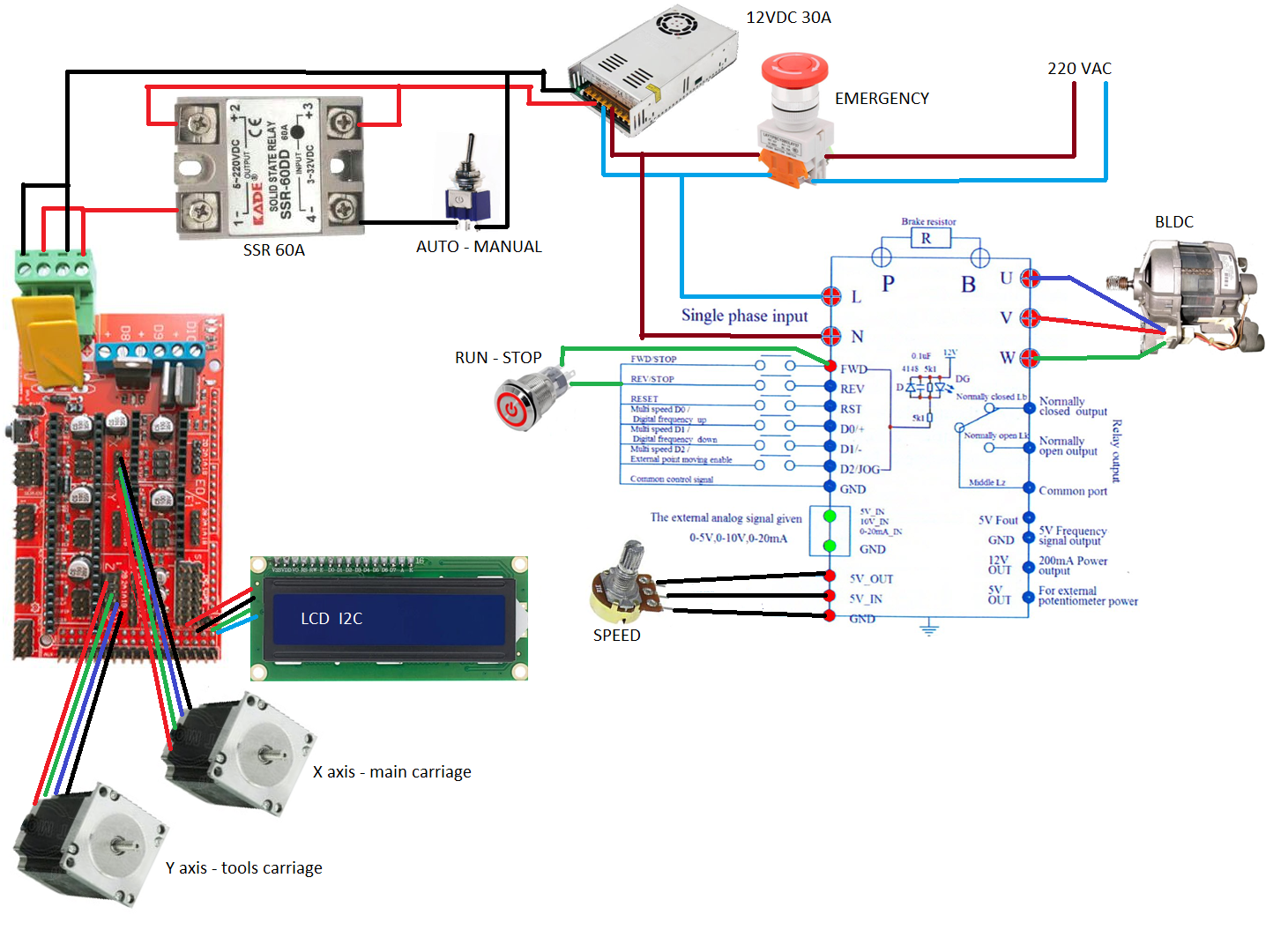

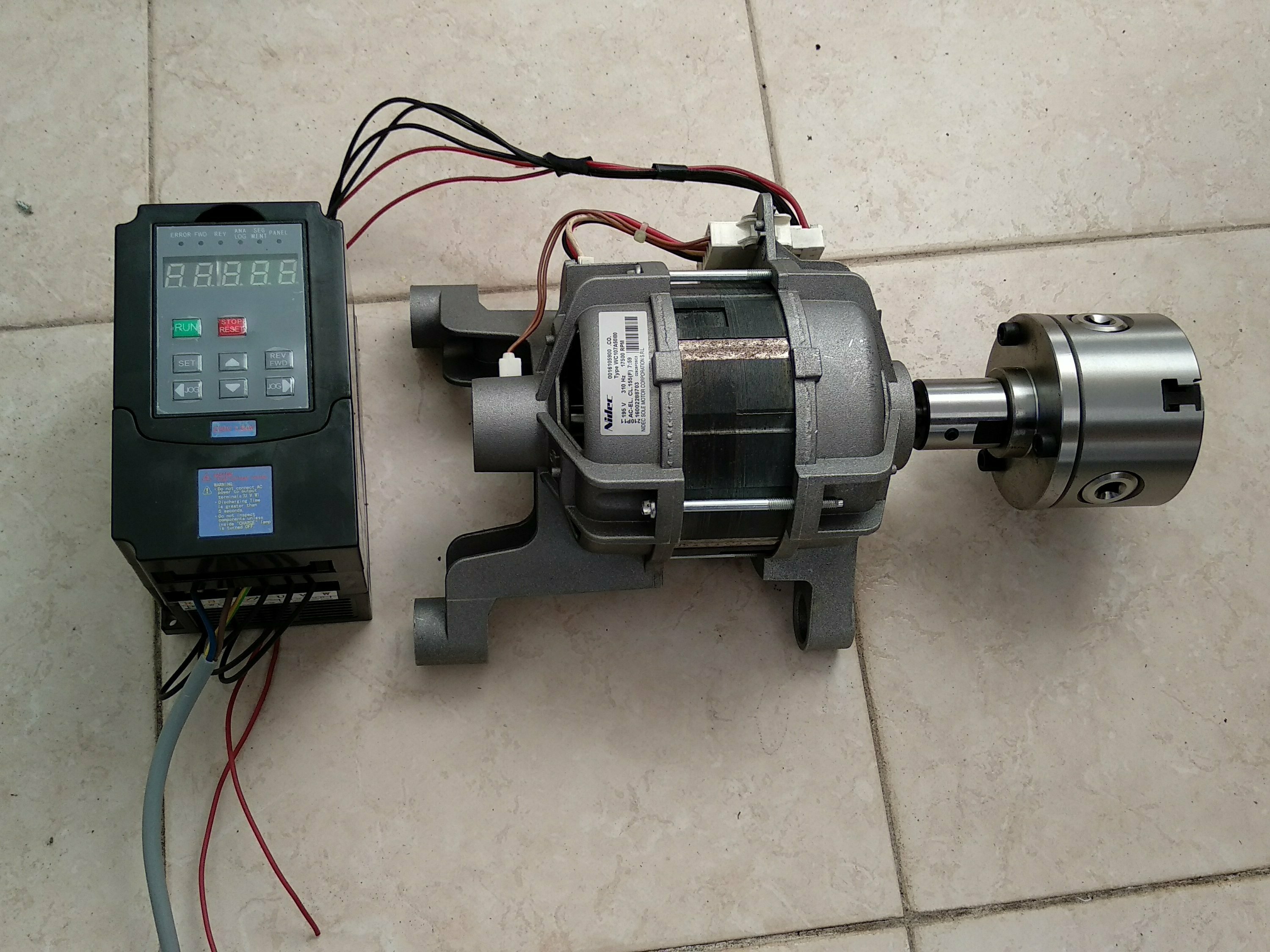

As previous version it uses a motor easy to get from faulty washing machines; at today they're almost all BLDC (Brush Less Direct Current), very similar as concept to the stepper motor we're used to,

The motor I use is an Ignis WM (Nideco motor) and needs 195VDC at 310Hz for max power and speed, but it can be driven with a lower frequency (less speed and without almost any loss of its 600W power); I opted for an VFD 220V 0-400Hz 1,5KW and 50Hz seems to be good choice for speed.

Furthermore it features wonderful bearings, engineered for big radial charge, perfectly balanced rotor and, last but not least, a very quit operation.

This lathe features:

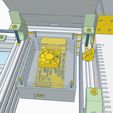

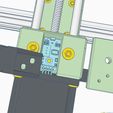

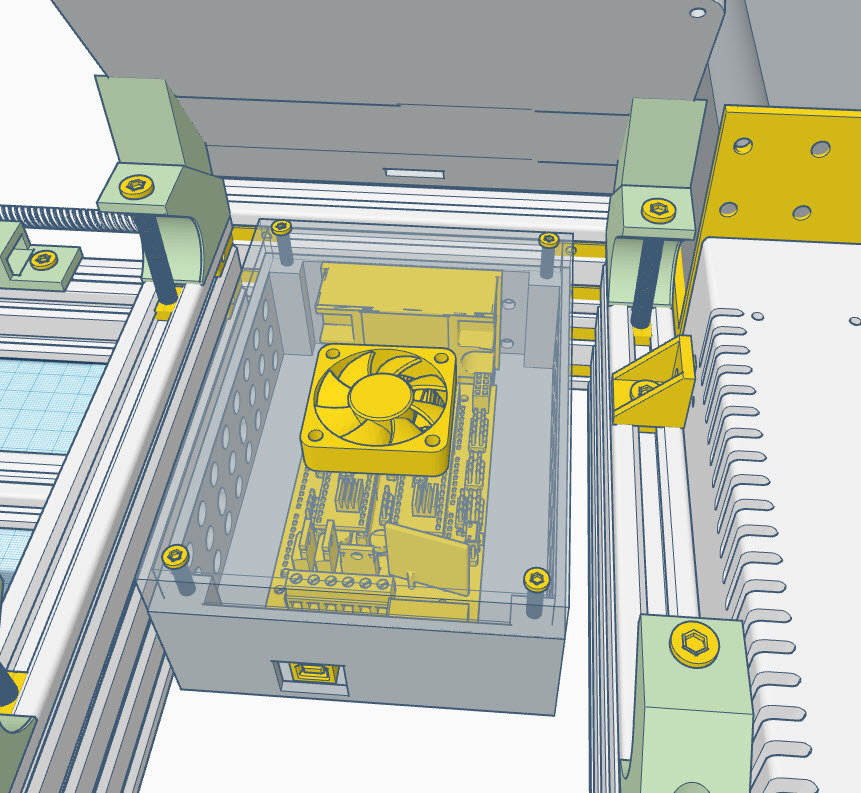

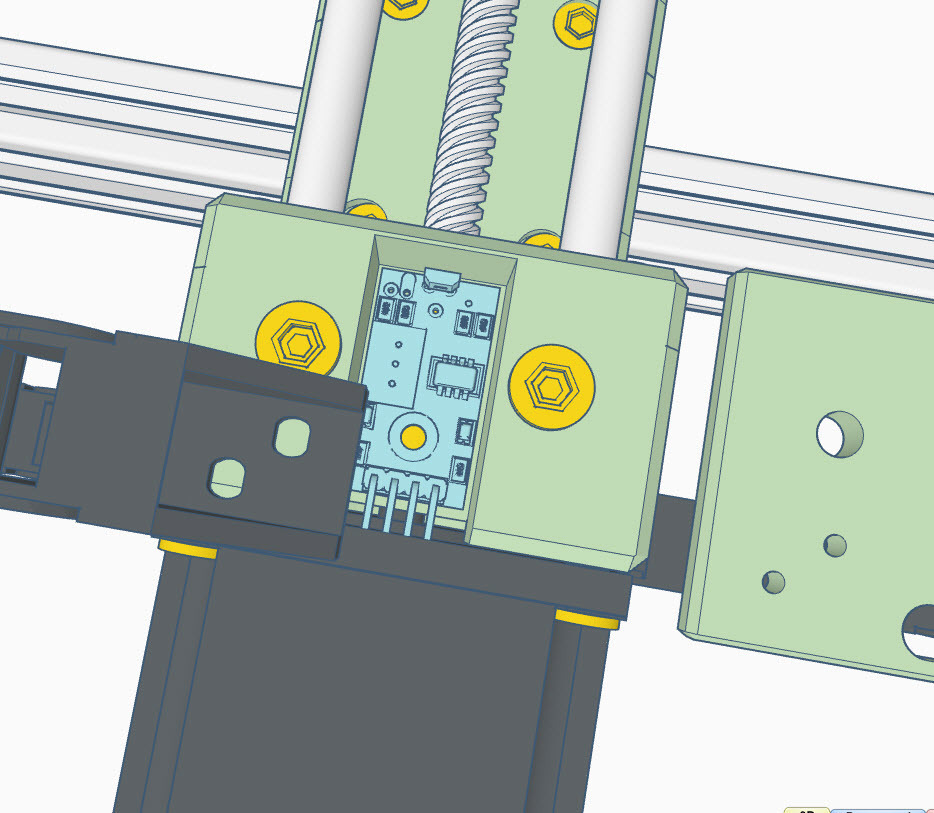

- CNC via Arduino Uno and Arduino CNC shield

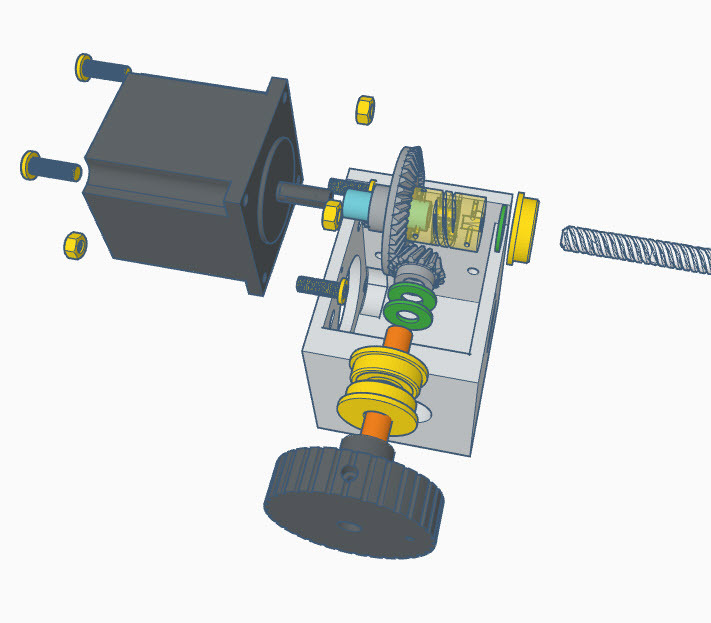

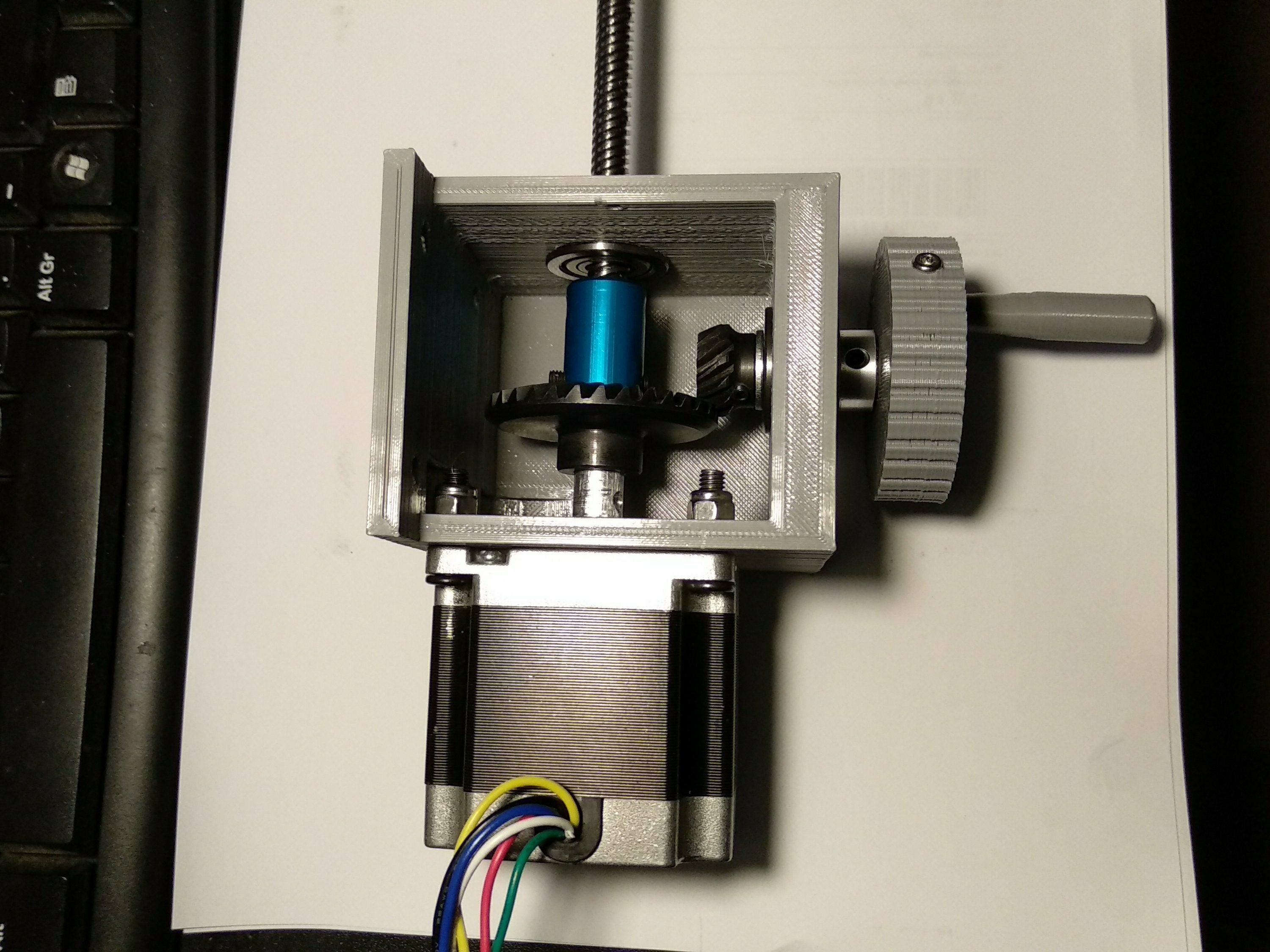

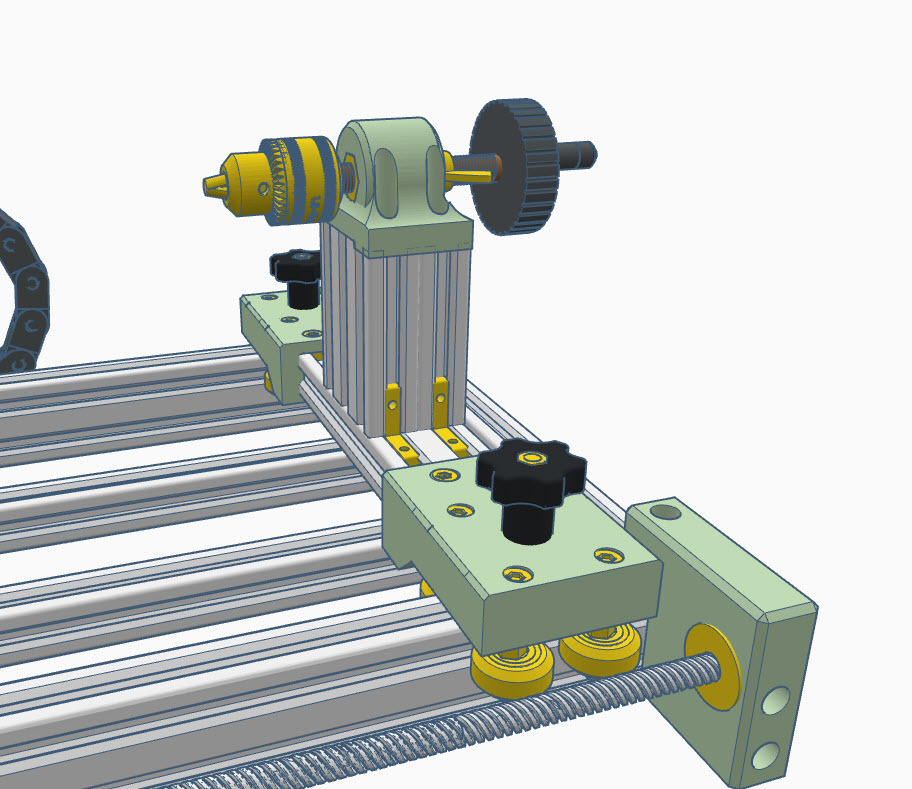

- main carriage horizontal sliding wheel to an intuitive position,in two versions, 1:1 or 2.5:1

- continuously variable speed via a cheap VFD BLDC controller

- rotating tools turret 360° at 22.5° steps

- tailstock carriage sliding with manual action, lockable in place

- can accomodate also every printed 80mm chuck

- very few printed items

If you don't like GRBL firmware,now you can use Marlin firmware (provided in MARLIN.ZIP, thanks to GeorgeA70),wich lets you work directkly from SD. To ease use of LCD I designed an additional control box and support (files pre-fixed with "Arduino_").

Items in STEP format are provided.

Video at https://dai.ly/k4iZ2hJq7BxdrryTcIO

I hope you like it...

Prints completed, assembled items, corrected all small imperfections.

2021-04-22

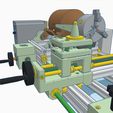

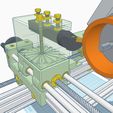

Designed brand new optional tools carriage, with protected lead screw and more intuitive handle rotation

2021-04-01

- uploaded the definitive items.

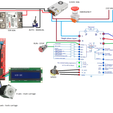

- uploaded electric schematic, read CNC / Manual operation section

- uploaded alternative LCD_X_switch_box_front to extensively use the VFD, just add a 10KOhm linear and a push button switch

2021-03-27

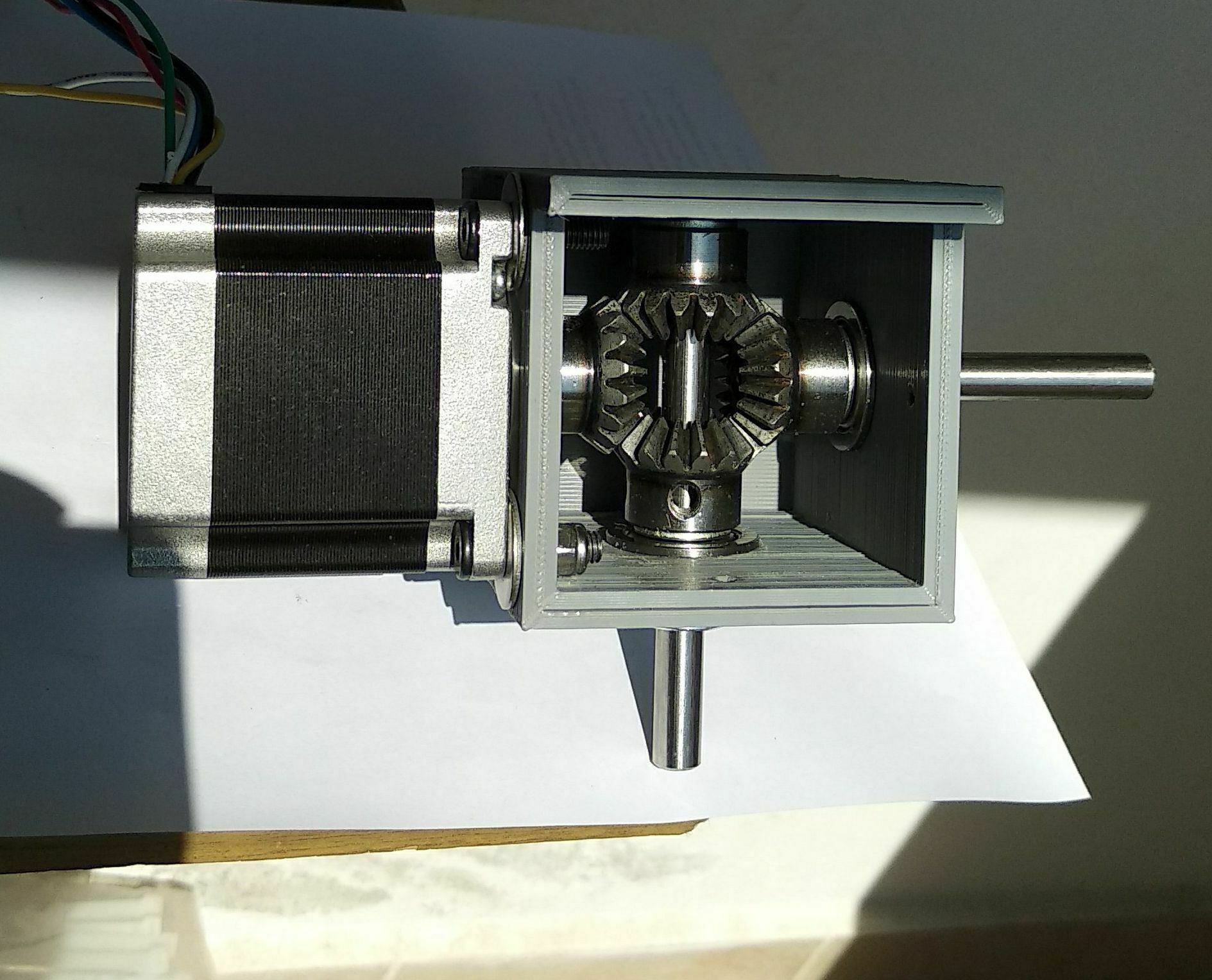

- uploaded alternative brand new gear box with cheap bevel gears from China

2021-03-25

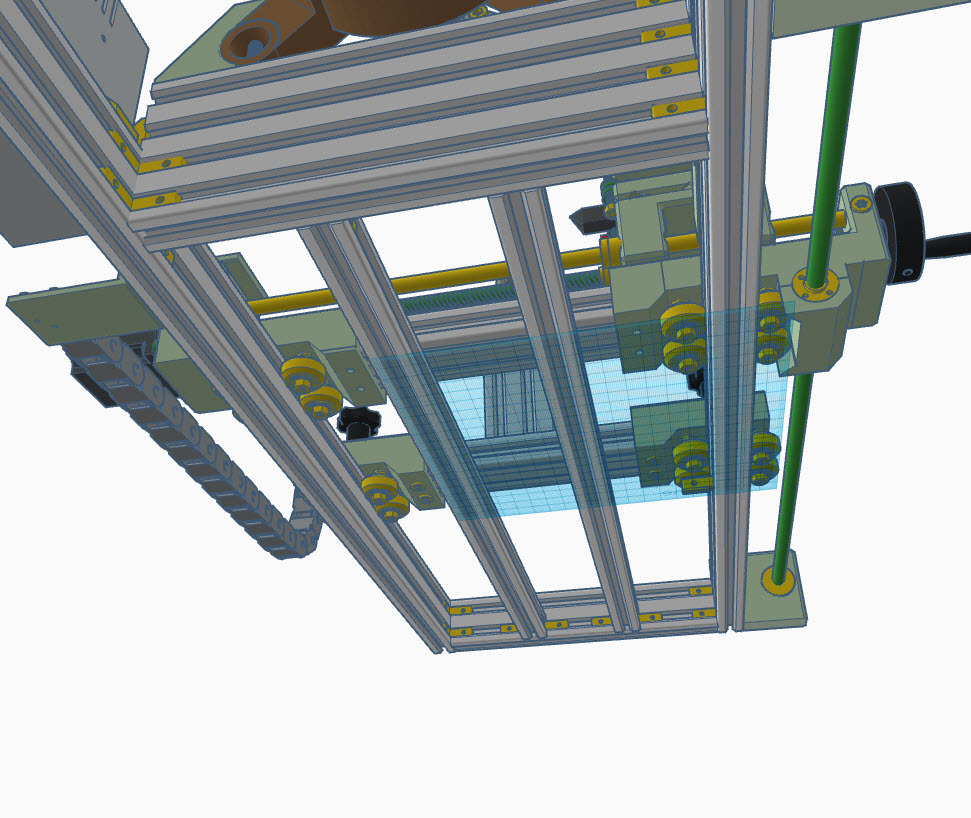

- uploaded brand new cross_slide and rotating turret for more heavy duty works (aluminium, brass) and 22.5° rotating steps. It supports tool bars up to 16mm.

Update 2021-03-23

- uploaded alternative control box to allow using Marlin firmware

Update 2021-03-19

- added a safety switch, it acts as main power switch too

- Uploaded remixed electronic and switches boxes, now placed in a more confortable position

- added 2040 profile back the motor for aesthetical purpouses

Instructions

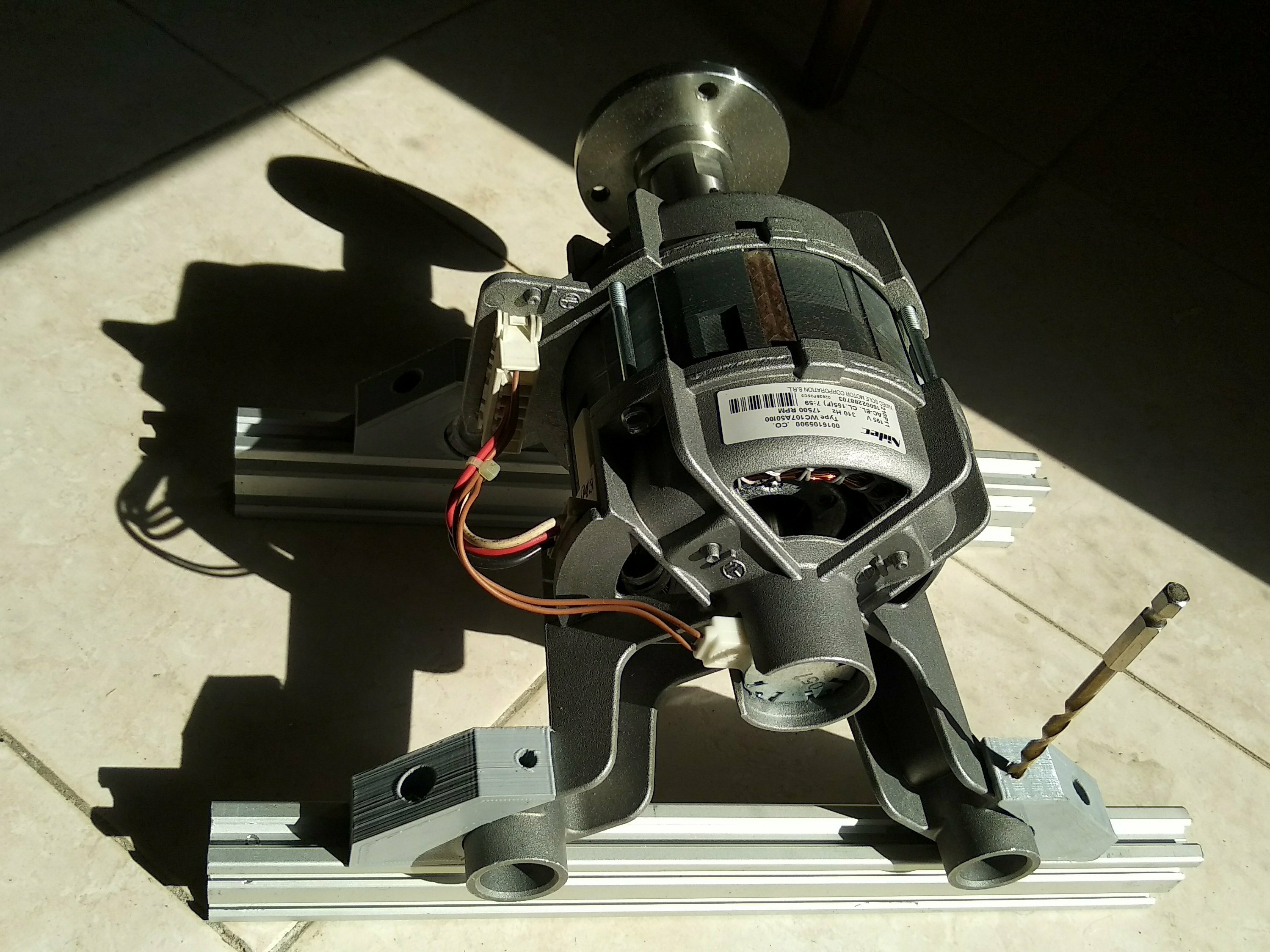

Motor:

- cut away 10mm from back foots (see red parts in picture above)

- put it exactly at center of profile and place the 4 foots

- move the tailstock close to the chuck and align the chuck center to it

- tight firmly the motor and the four feet screws

- apply the 14-19mm adapter to the motor rotor, then tight the two grubs enough to let a mark on the rotor

- remove the adapter from motor and with a 4.5mm drill bit make a little cone to each mark on the rotor, to fit the grub points

- apply again the adapter and tight well the grubs

CNC / Manual operation:

It's only necessary cut off the power to the Mega board...

SWITCH BETWEEN MAN-AUTO ONLY WITHOUT POWER APPLIED

or you could fire up the drivers!

BOM

Electronics:

- n. 1 washing machine BLDC motor

- n. 1 Arduino Mega 2560 board

- n. 1 RAMPS 1.4board

- n. 1 12 pins ON-ON switch

- n. 1 button self-locking switch

- n. 1 safety switch

- n. 2 Nema23 steppers

- n. 1 12VDC20A power supply

- n. 1 40mm fan 12VDC

- n. 2 hall proximity sensors

- n. 1 cheap VDF 1.5KW 3 phase controller

Mechanics:

- n. 1 K11-80 chuck

- n. 1 14mm base for K11-80

- n. 1 14mm to 19mm adapter for above adapter

- n. 1 Bevel gear 1.5 Modulus 20 teeth 6.35mm bore

- n. 3 Bevel gears 1.5 Modulus 20 teeth 8mm bore

- (bevel alternative) n. 1 Makita 9523 gears set, very cheap

- (bevel alternative) n. 1 8x10mm self-lubricating sleeve

- (bevel alternative) n. 5 M8x20x1mm washers

Body:

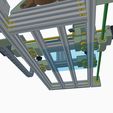

- n. 2 profiles 2080 230mm

- n. 2 profiles 2060 73mm

- n. 2 profiles 2040 750mm

- n. 1 profile 2040 230mm

- n. 2 profiles 2040 175mm

- n. 2 profiles 2020 557mm

Bearings:

- n. 5 608F bearings

T8:

- n. 1 T8-2 leadscrew 610mm

- n. 1 T8-2 leadscrew 390mm

- n. 4 T8-2 round nuts

Rods and bars:

- n. 2 8x395mm rod

- n. 1 10x150mm threaded rod

- n. 4 LM8UU sleeves

Wheels:

- n. 16 24mm Delrin wheels

- n. 16 5mm eccentric nuts

MISCELLANEOUS

- n. 2 1/4" to 8mm flexible coupler

- n. 2 8x3mm Neodymium magnets

- n. 1 10mm socket drill chuck

- n. 32 90 degrees profile locks

- n. 4 corner profiles locks

- n. 4 8mm collar locks

- n. 4 M5x45mm screws

- n. 20 M5x40mm screws

- n. 3 M5x35mm screws

- n. 14 M5x8mm screws

- n. 1 M8x30mm coupler hexagonal nut

- n. 29 profile screw locks

- n. 30 M5 nyloc nuts

- n. 1 M5 blind nut

- n. 10 M5x10mm screws

- n. 1 M5x40mm screws

- n. 2 M5x55mm bolts

/https://fbi.cults3d.com/uploaders/15451373/illustration-file/6b97063c-2091-4d62-a7dd-67b0ccd5383f/1.jpg)