This is a semi-scale assembly of the Volvo Penta IPS (Inboard Power System). It is designed to be functional, rather than detail exact. The VP IPS consists of a hull assembly, a steerable pod with forward facing counter rotating propellers. The main idea behind the full scale design is that the propellers operate in undisturbed water.

This is a heavily "in progress" project that I'm publishing now because I've made a decision to go forward with another project, and it would be a bit sad to have this project just laying around so I figured better publish it so that someone can have fun with it rather than leaving it unused. Maybe I'll build it myself later, as I would like to build a Delta 54 IPS with three of this, which would be truly awesome. :) but I have another big project that I've decided to go for instead now.

So if you haven't figured it out yet, I haven't assembled this myself. I've printed a couple of the parts and checked that they do print, like the pod. But from there on you are on your own to experiment.

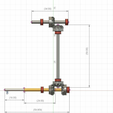

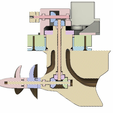

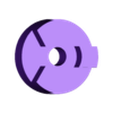

My design uses an inner 2mm propeller shaft for the front propeller, and a 2mm inner and 2,5mm outer diameter brass tube as the counter rotating shaft for the aft propeller. I've included a picture of the lengths of the shafts and tubes. I also made it so that a short piece of brass tube is glued to the inner shaft at the aft end, and the bevel gear goes outside of it. I think the pictures speak for themselves.

Other than that it's worth to mention that this design includes a passive water intake/outlet for cooling water for an electric motor. The water enters the pod right behind the propellers, goes up through a sculpted cavity through the steering actuator ring. The idea is to cut short pieces of 3mm aluminum tube and glue them as hose connectors on the actuator ring, one for water inlet and one for outlet. The outlet goes the same way as the exhausts of the full scale version. The idea is that this should work even when the pod is turned.

The design uses 6pcs ball bearings 6mm outer, 3mm inner and 2,5mm thickness.

(same ones as I use on my trains).

The vertical shaft and the upper horizontal shaft can be made from carbon fiber, but the inner propeller shaft should not be carbon as it will tare too much on the brass tube.

Feel free to ask anything in the comments, but I highly suggest you print the parts and have them in your hands before you think about assembling, as I haven't even figures out myself the best approach. :)

Would be truly awesome to see if anyone else can take on this project and show me if it works! :)

Oh, and there are two O-rings to be used as seals for the pod against the hull installation. I don't know which size is the best, I suggest you experiment with different ones. If they are too thick the pod will not turn easily enough for the servo, and if they are too thin it won't be water tight.

The servo to be used os a hobbyking mini servo. Print the gearbox house and you can test your servos and see which fit. I don't recommend taking on this project and order components just for it, it's too experimental for that. It's better to print all the parts, install the shafts and gears and make it turn first, and if you succeed with that you can go ahead and install servos and motors. Just making it turn smooth will be a challenge for sure! but who doesn't like a challenge? :)

By the way, if you don't want to waste 6pcs of ball bearings, you can print dummies in PLA... it actually works pretty good for many applications.

Another recommendation is to use thin nylon or teflon washers for the gears. I've added space for them almost everywhere so when you push the gears in place on the shafts, put a washer between the gear and the ball bearing (or gear and house) and that way you won't end up friction welding gears to their surroundings.

UPDATE 2018-09-03 Added seal between the rotating parts and the steering actuator ring. This seal is 0,4mm thick and can be printed in flex material. If you need to make it thinner, just stop the print after desired number of layers.

/https://fbi.cults3d.com/uploaders/16207324/illustration-file/4549a7f3-5a68-4f9f-8f4a-f9ff2355edd4/Skarmavbild_2018-08-21_kl._23.49.09.png)