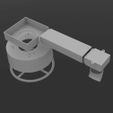

I saw several HEPA air scrubbers for IKEA Lack enclosures, but the issue that I kept running into was not being able to find the right fan or the right filter or the filters were not in stock. So I found available filters and a fan and made my own. The goal was to make a modular system so I can try different ducting, try different filters, or if the filters I'm currently using become unavailable I am able to swap out what I need. I also wanted to be able to direct the filtered air down and away from the intake and create both a convection style distributed heat and more effectively cycle the air in the enclosure.

This is still a work in progress and I started to make a dual end piece that will both recirculate air and exhaust it using a closable vent, but I have not actually printed those parts out to test. I included the STL's in case anyone wants to give it a try.

UPDATE: I made a new exhaust vent. I am printing it out now to test. The "Exhaust_Tube" should slot into the top hole of the "Air_Duct_Cap_Dual", and through a drilled hole in the top of the enclosure, the "Exhaust_Base" has a slight recess in the bottom to align with the tube, and the "Exhaust_Cap" screws down and the outer edge fits in a small groove in the "Exhaust_Base" to help minimize air leakage. The cap is removable of you want to maximize exhaust. I will probably make some changes to the "Air_Duct_Cap_Dual" as I test to alter the direction of flow if it isn't exhausting as much as I need.

UPDATE 3/29/2021: I installed the exhaust vent. I discovered the pipe was shorter than I wanted. It was flush with the top, so I made a slightly longer version so it slots into the top vent cap. I found a hole saw that works perfectly. Size is 1-7/8". Hole Saw

Here is the enclosure I am using:

IKEA Lack V2 (https://www.prusaprinters.org/prints/3673-prusa-enclosure-v2-mmu2s)

What you will need is a variable speed fan of 120mm, Flintar or compatible HEPA filters, and some 1/16" or approximately 1.5 mm thick adhesive foam.

Fan

Filters

Foam

I had extra screws left over from assembling the Lack V2 enclosure, so I used those.

3 x 2” wood/drywall screws to attach the filter housing to the enclosure.

6 x 5x20 or 12x3 3/4" screws to attach the fan, fan housing, and filter housing together.

Assembly

NOTICE The air duct is not reversible. The top that should have the foam and contacts the lid is slightly thicker, The bottom side has a slight rounded bevel. If you flip by accident you should see a step between the duct and duct end cap.

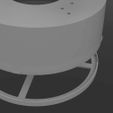

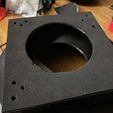

- Cut a foam ring to put around the intake of the fan and cut a square for between the fan housing and filter shell to make them air tight. I used 4mm screws to poke holes in the foam and cut a circular hole for the fan. The Flintar filter has foam on the end so that seals itself.

- Put the fan in the fan housing and filter shell on top. I used 4mm screws to put in the fan holes to line everything up. Then took them out one at a time and screwed in the 5x20 or 12x3 3/4". Leave the 3 outermost holes empty, those are for attaching to the lid of the enclosure.

- I used a zip tie on the fan power cable and placed that inside the housing as a strain relief.

- Cut foam backing for the fan and the air duct pieces. This is meant to prevent any resonant vibration from transferring to the lid. I have not done any testing without the foam to know if this actually helps, but I had plenty of extra foam and I figured it couldn't make it worse.

- To attach to the top of the enclosure, I first used a pencil to mark on the inside/bottom of the Lack table where the printed pieces of the enclose touch. This is so I know how much to inset the filter so it clears the sides when opening the lid. Remove the lid from the enclosure, and using the pencil drawn lines as reference, measure 5mm inset to the fan housing. Both the side and back of the fan housing should be 5mm from that line. You could probably move the housing further toward the back since the filter will swing away when opening, but you will need to have clearance so the side of the filter clears the printed enclosure side.

- Screw the fan/filter housing down and then attach the duct. The long duct slots into the fan opening, and then into the end cap which is then screwed down.

Because I do not have the MMU2 but have the holes cut in the acrylic, I am just feeding the fan power cord through one of those holes.

The filter is a fairly tight fit in the filter shell, but that is by design. The Flintar filters have two fabric tabs to help pull it out. The filter cap has 4 slots that twist on and are held by the 4 tabs on the filter housing. It's mostly friction fit, but it works well enough for me.

/https://fbi.cults3d.com/uploaders/15742500/illustration-file/53a92b92-ffe6-4838-a79d-e3c4eb19e3de/attached_outside.jpg)