#AssistiveTech

This will be my entry to the AssistiveTech competition.

Its a wheelchair for people that need one!

I call it 'HU-GO'

I am adding more parts daily.

I have modelled most of it now, I used ArchiCAD 18 which is the software I use for my Architectural work.

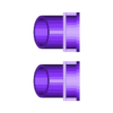

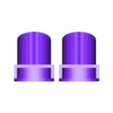

I have just started 3D printing the first bits.

update 1: I have finished printing all the parts now (25th oct 2015 and the cutting of the MDF started today ( my jigsaw ability leaves a lot to be desired)

update 2: I am printing one small wheel and if I have time I will print the other (28th oct 2015).

update 3: arm for chair has been modified (the new one uses less material and quicker to print) I will leave the other file in case someone wants that one instead.

update 4: I have almost finished (31st oct 2015), I learned how to do sewing today. So I did the cushions and the armrests.

update 5: what next now that it is finished ?(Sunday 1st Nov 2015 Australia)

update 6: Its fits in the back of my little car (so if it fits in a MINI then it fits in most cars(photo added to gallery)

update 7: We have a very short youtube video here of the 3D printed wheelchair in action (dont mind my friends at work who are a little shy):

http://youtu.be/9n2WbFhp-DU

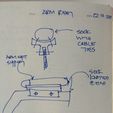

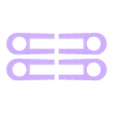

update 8: I am adding the sizes of nuts and washers I used for every connection(see photo added below). (the holes are bigger and could take a large bolt if you need to secure it more, but from my experience they are strong enough

update 9: I have added more photos with a wide angle lens and much closer shots.

update 10: Today I got a response from the Mens shed (a government organisation that helps men suffering depression and helps them with projects and company).

update 11: I was contacted by a Sydney based Australian organisation today who have offered a lending hand.

update 12: I have made a new video on youtube to explain this project from my own words, excuse the heavy spanish accent.

http://www.youtube.com/watch?v=ZDljuV9umbE

update 13: main photo cover updated (fixed spelling mistake and changed colour a little)

update 14: I went to my first Brisbane meet up yesterday to talk to people about 3D printing and Don was a lovely man who is passionate about 3D printring also making his own printers, we will collaborate soon. I also met Alex Uhde from hackaspace Brisbane (Will have to check it out next week)

http://www.meetup.com/Brisbane-3D-Printing-Meetup/photos/26574579/444510495/?a=pc1_cl1

update 15: I would to thank my filament supplier for his second to none approach to customer service. for his fast delivery when I have needed it most (mostly when I think I have enough but I do not) and for donating filament for this worthy cause many thanks. check out http://blueprinted.co

His filament boxes have a sticker that read 'WARNING ! CONTENTS MAY INSPIRE INNOVATION'

UPDATE 16: Finally I extend my apologies to my Fiancee Jacara for all the noise I made while she was studying for her final tests and assignments while I was building the wheelchair. I love you! and thankyou for listening to my never ending 3D printing stories!

update 17: there is an article about this wheelchair already here: http://3dprintingindustry.com/2015/11/16/hu-go-an-ambitious-3d-printable-wheelchair-on-thingiverse/

update 18 (14-12-2015): the wheelchair will appear on my local paper! They are coming to my office to do the photoshoot this Thursday (funny how I met them!, I answered a call for people to dress up in star wars for our local cinema,which will feature in the newspaper, when I got there (I am Darth Vader) I began to chat to the editor and I pitched what I was doing with the wheelchair, she gave me her business card and today we organise the day for them to come over)

update 19: I guess the announcement will be any day now.....If I win I will sell one of my old 3D printers, with the money I will buy a brand new little 3D printer and have it sent to Chile where I will be making them first with the help of a lovely young friend I met there!!

I have emailed Ikea foundation http://www.ikeafoundation.org/ to see if they would like to help me. We wait and see

Dear Hugo

Thank you very much for your interest in responding to the Village News article on Spring Hill Men's Shed.

I am certain that your expertise in 3D printing would of worthwhile appeal to shed members.

At this stage, however, we are not yet operating as a men's shed, but are still in the process of forming an incorporated organisation for the management of our shed. We do, at least have a venue for the shed, in the undercroft of the Bedford Park Community Hall in Love Street Spring Hill.

I have noted your willingness to become involved, and will contact you again when we are about to have our next meeting.

regards

Rob Collins

on behalf of the Men's Shed Spring Hill Management Committee.

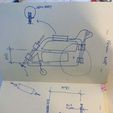

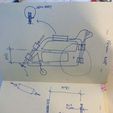

update 11: I have the sketches for the big wheel which i know know i can 3D print also.

i am adding those sketches now!!

UPDATE 12: THIS DESIGN HAS BEEN SHORTLISED FOR ANOTHER COMPETITION ORGANISED BY THESE GUYS (I THINK IS THE INTERNATIONAL COMITTEE OF THE RED CROSS)(12-15 TEAMS ONLY, I AM A TEAM OF ONE!)

http://www.enablemakeathon.org/

Start by share it wherever you can and start printing it worldwide!!!

Why not make it a school project.

some kids can sew the seat covers, others in wood class can make the frame and others can 3D print the parts, the seniors could design it better! go on its for a great cause.

I have contacted one school already near me to see if they would like to get a talk on 3D printing and its benefits from me free of charge (waiting for the school principal to call me back) then good things could start.....

I hope I can make the deadline. (update....I made the deadline and we now have a fully made functional wheelchair anyone can put together)

I decided to create this wheelchair because I have used one before due to my own illness,

I was a Sydney 2000 Olympic volunteer and part of my job then was to help people that are a different kind of perfect move around the Olympic park.

we even received training how to operate a wheelchair during the induction.

I have been 3D printing many things and for many people over the last 3 years and I think is time I begin to design/make something for a noble cause.

So, I thought I should pay it forward and create one that anyone in the world could make and assemble with a very common cheap parts.

I visited my country of Birth Chile a few months ago and I saw first hand how 3D printed parts for different kind of perfect people could transform their lives but sadly they didnt know where to go to get their needs met or that it could be very cheap.

I strongly Believe that everyone in the world deserves to be able to move about and a wheelchair should not be a luxury item for the few/well off.

It should be a tool that anyone should have access to use.

So, I am accepting this challenge with the 'hugo' version 1.0

Version 2.0 will have 3D printed wheels/ and or hubs also but due to the deadline I will leave it for later.

I only found this competition yesterday (19th of October 2015) so I am busily trying to get it all done in time.

Wish me luck! I am spending all of my spare time with this project.

This is a lovely thing a friend does for a mate but it should not have to be this hard!!

http://laughingsquid.com/chinese-student-piggybacks-his-disabled-friend-to-class-for-three-years-so-he-wouldnt-miss-out-on-his-education/

So, I am attempting version 1.

Version 2 will have 3D printed wheels/ and or hubs also but due to the deadline I will leave it for later.

I only found this competition yesterday so I am busily trying to get it all done.

The material list will be like this: (will be adding more as I need it)

-Plywood/MDF 16mm thick

-roll of plastic (1 kilo exactly is what will be needed to print all the components!!)

at the end I will rename each part so it has its weight in grams in case you are wondering if you have enough.

-zip ties (to support not load bearing components instead of using nuts, bolts and washers which are heavier and more expensive ( I used these for the seat support beam ends)

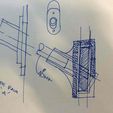

-rods 'broom sticks' of two sizes (50mm for cross bracing and 20mm for the others)

-nuts and bolts (will specify how many, what type, size, lenght,etc)

-paint (because the frame is kind of chunky a nice vibrant happy colour would be great (I will do version 1 in red because it will go faster)

-2 old/new long 'socks' for the arm rests

- fabric for the seats (I was thinking flour bags) and or old tshits

tools required

-Jigsaw

-drill (hand held or electric)

-screwdriver

-spanner (will specify size)

-access to a 3D printer

-access to needle and thread

-pair of scissors

and a bit of room to make it. (I live in a small apartment so my workshop was my balcony which I had to leave everytime my little dog needed to go to the toilet, he is shy and doesn't like to go when there are people watching), so a little more room would be best and a bench/table would be great to have too.

finally, I dont like the term disabled so instead I replace it with "a different kind of perfect" which I got from here (its far nicer)

http://themighty.com/2015/04/the-term-that-describes-my-daughter-better-than-special-needs-or-disabled/

note: I have started to put PDF's now.

once I do the frame today, I will make a cad file of it in PDF and DWG and STL in one piece so that maybe someone with a laser cutter machine big enough can cut it automatically.

also when the frame is done i will assemble it and begin to take photos of the real thing!!!!

This project has taken a great amount of time, effort and resources to design and build.

(As you know any prototype is expensive at first, I am happy to wear the costs)

My purpose is to share it with the world for free, however a small contribution would be a huge help to continue its development.

please go here and help me if you believe in this worthy cause.

https://www.paypal.me/justonedollar

My dream would be for this project to be copied by someone like IKEA and mass produce this flat packed and shipped wherever these might be needed as part of help that countries offer one another.

Anyone with questions or help, done hesitate to send me a message and I will endeavour to reply ASAP.

Also if anyone would like to donate a 3D printer for this cause don't hesitate to get in touch with me.

It doesn't even need to be big or fancy, i can modify the wheelchair parts to fit their built area. you would be doing a great thing

/https://fbi.cults3d.com/uploaders/5125683/illustration-file/1339e1b8-8d1c-489d-8c32-8690f3ba25c3/unnamed.jpg)