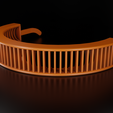

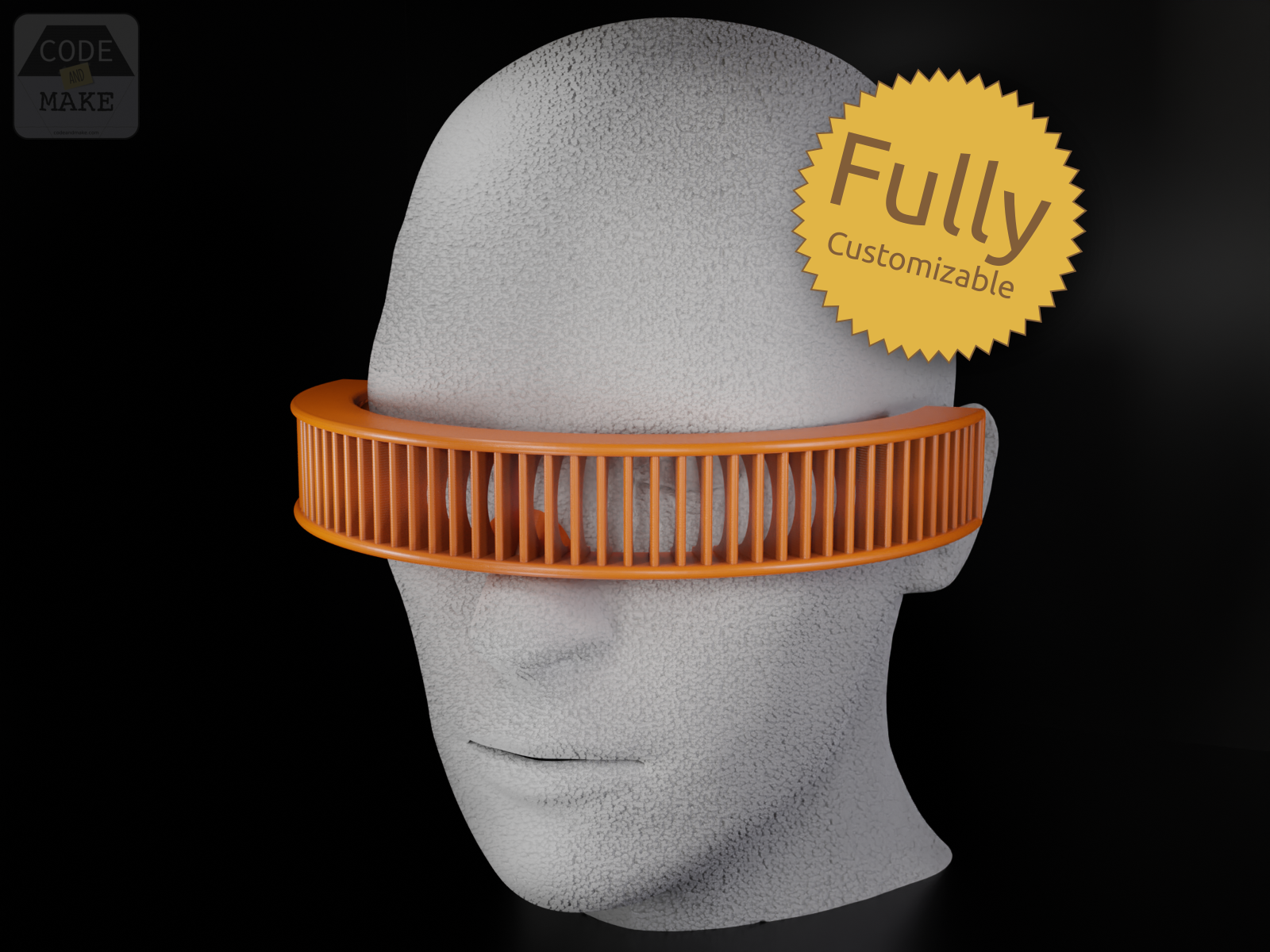

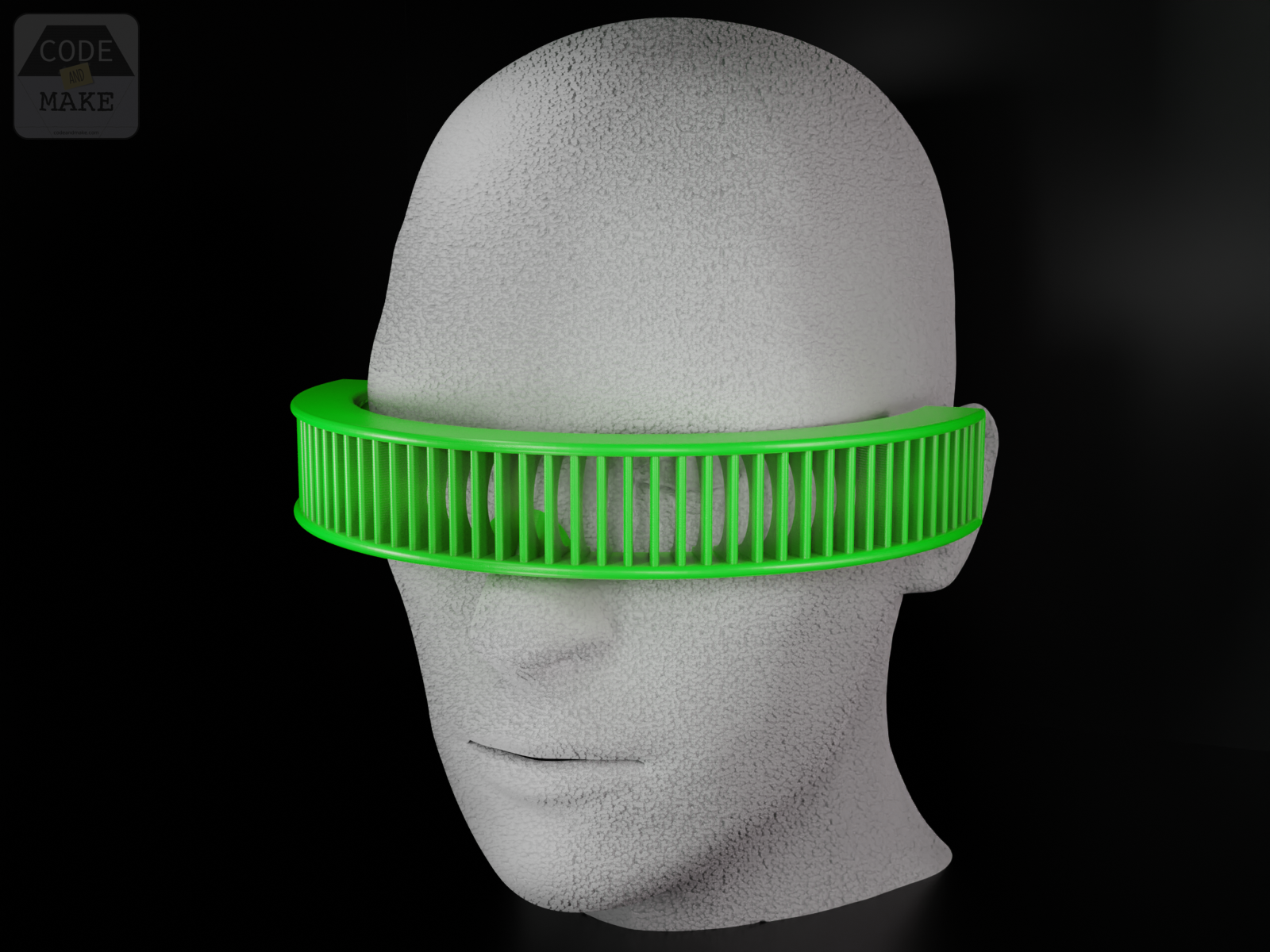

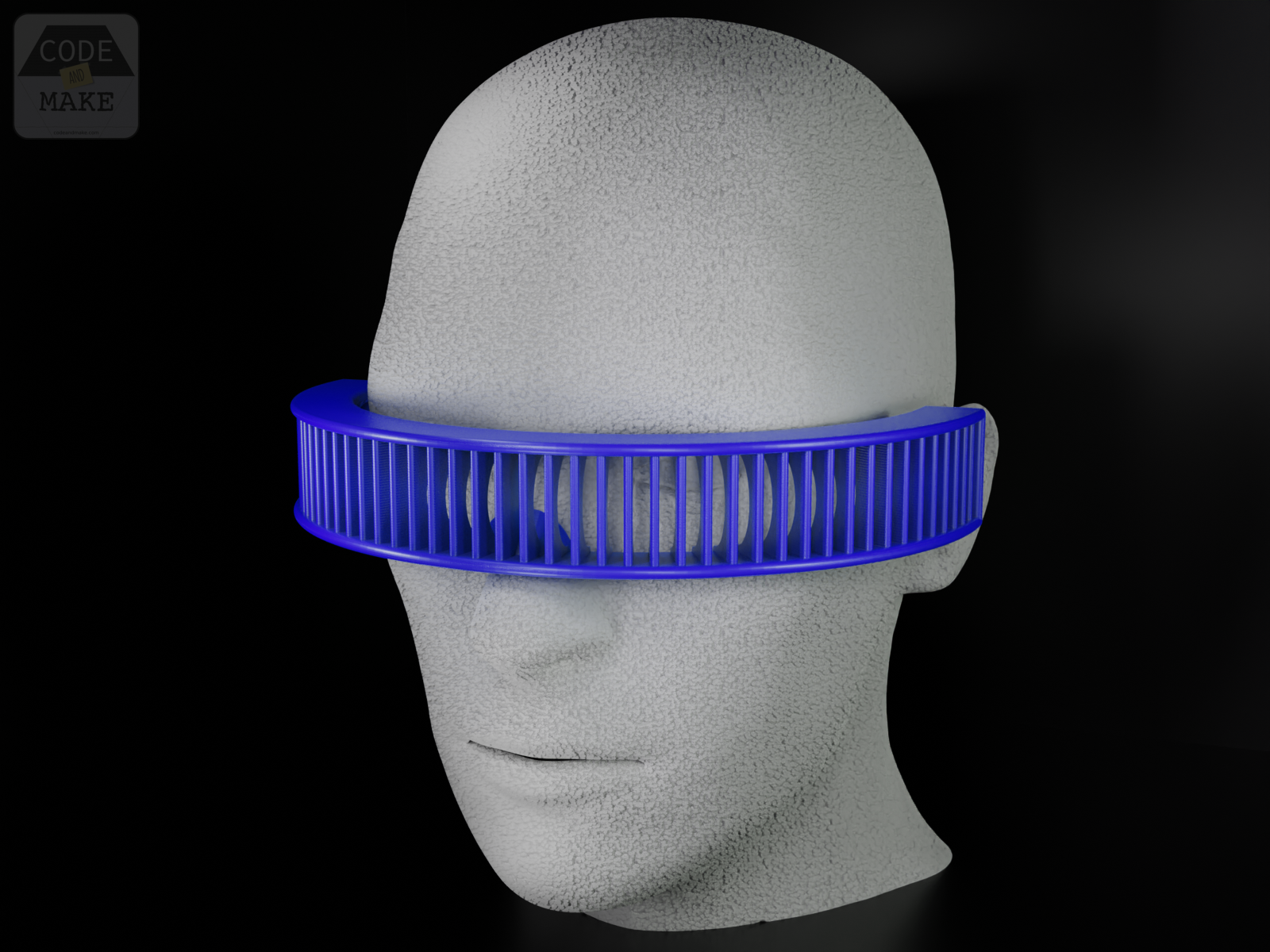

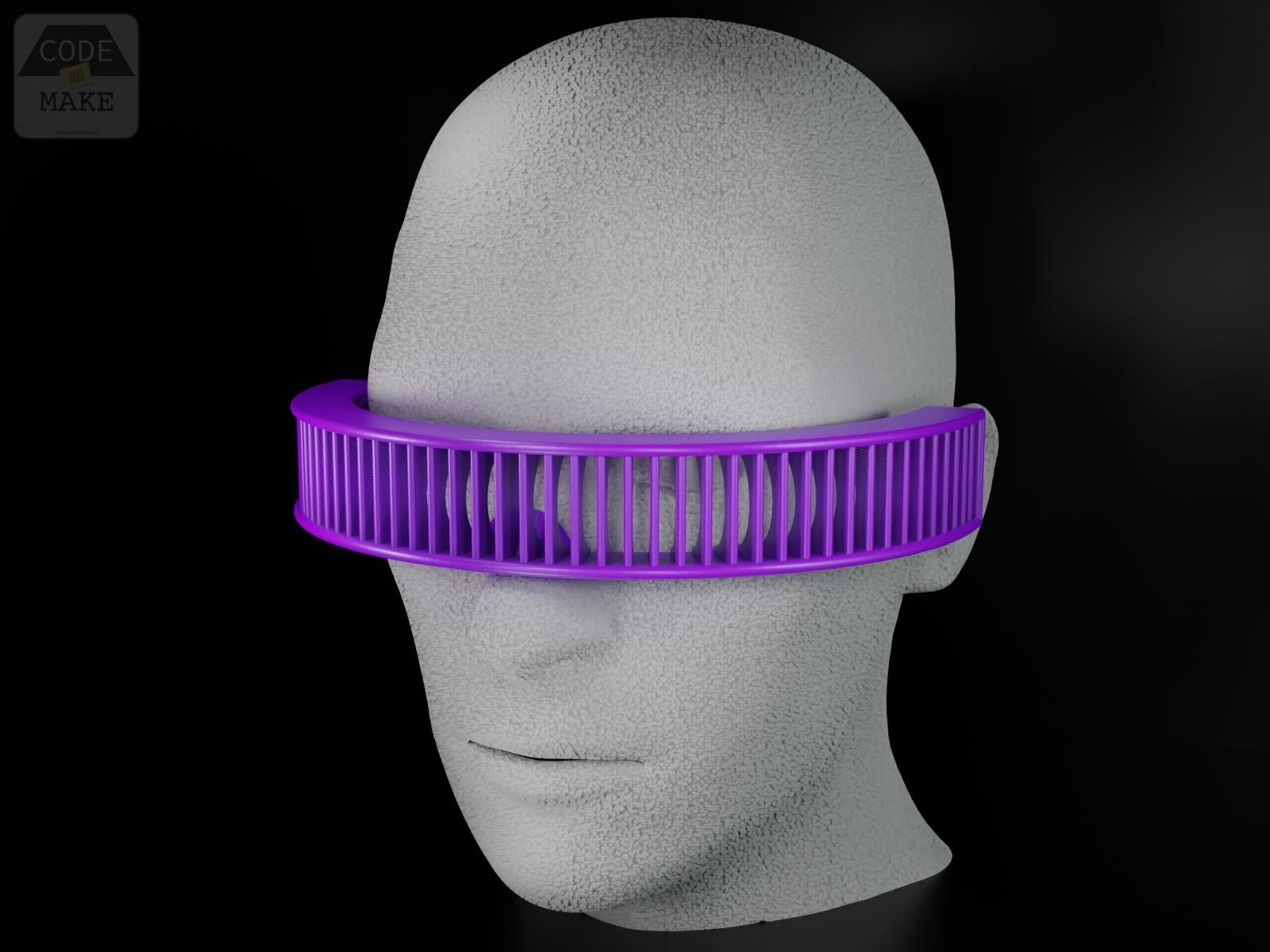

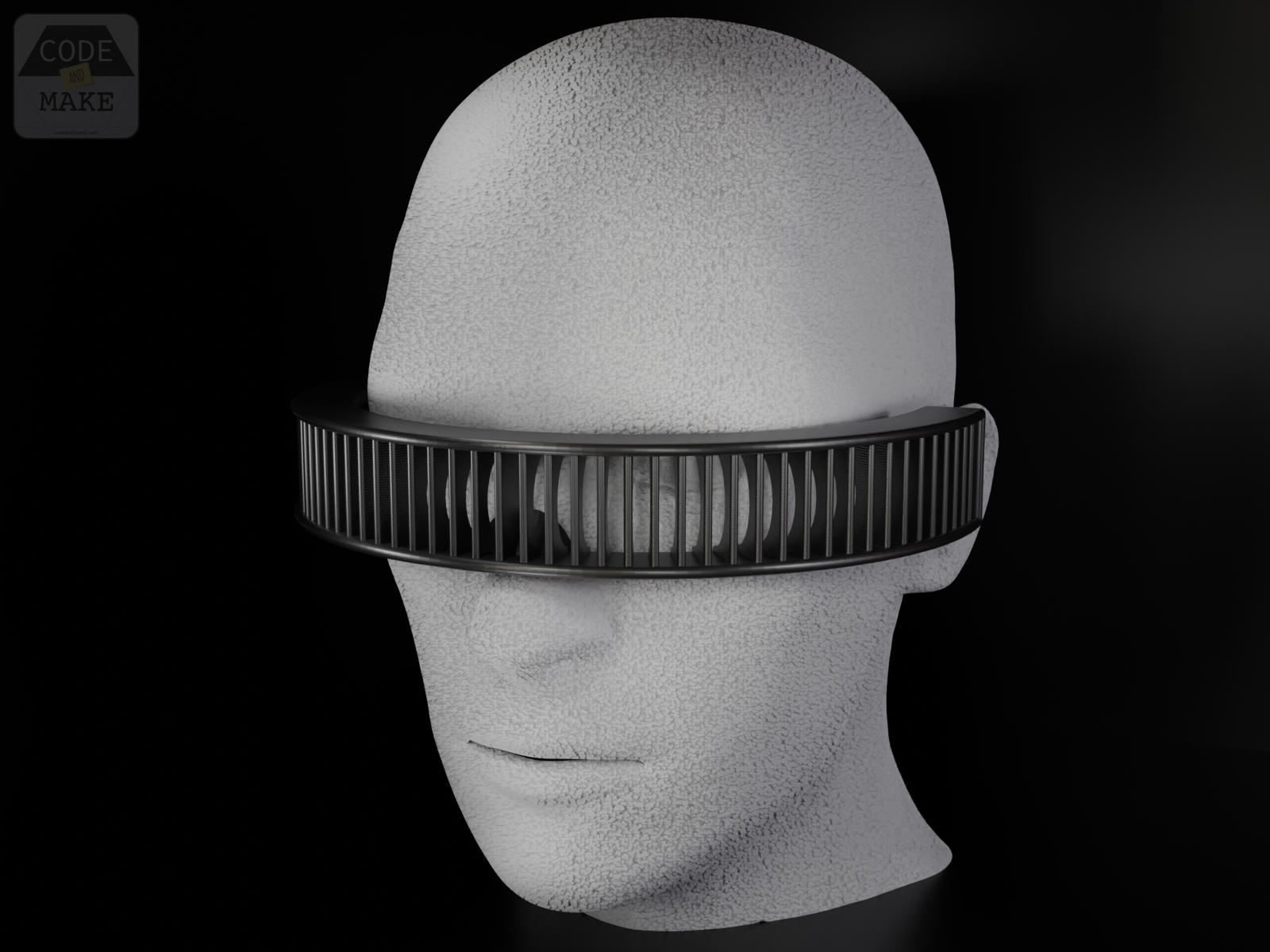

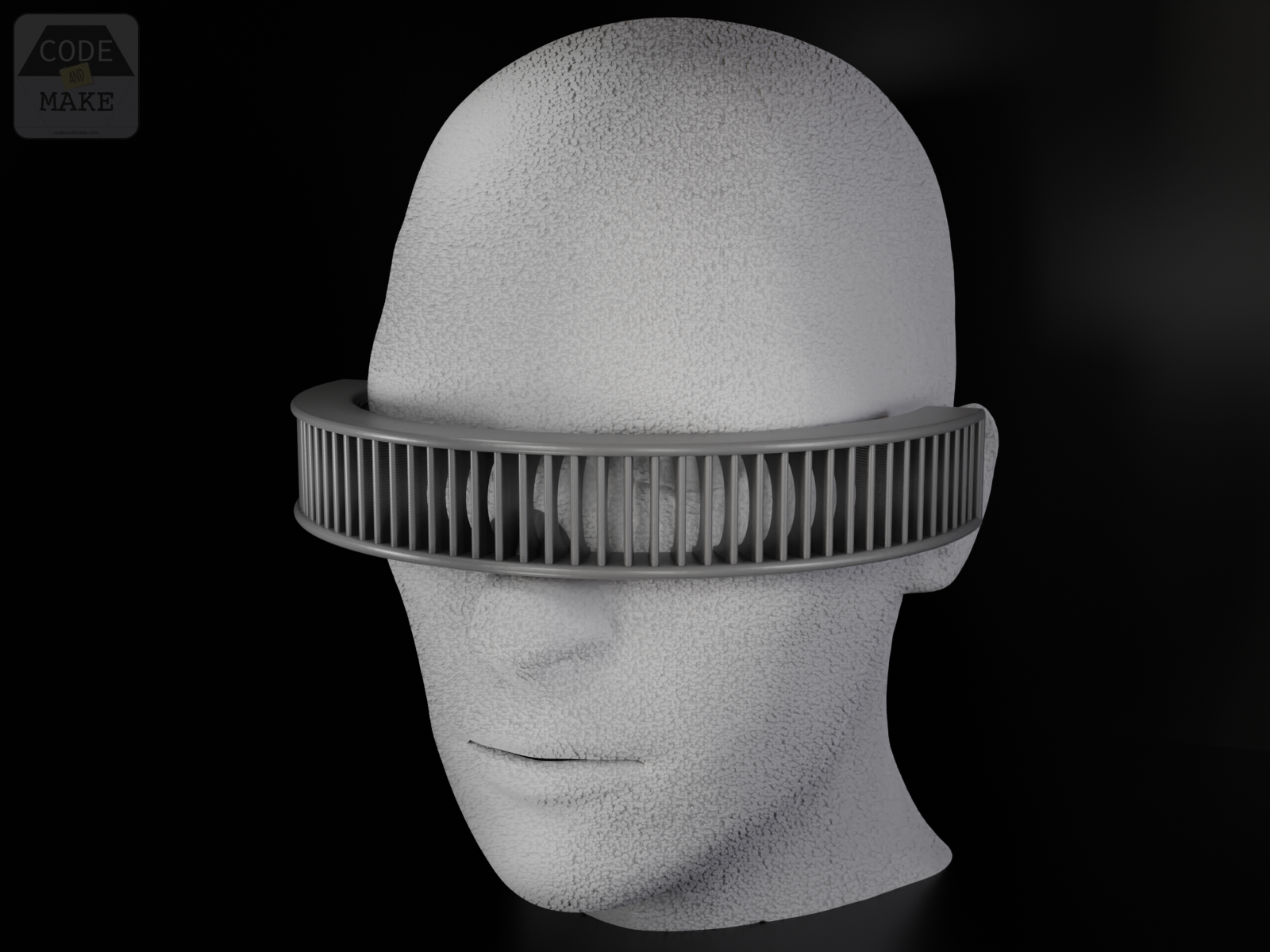

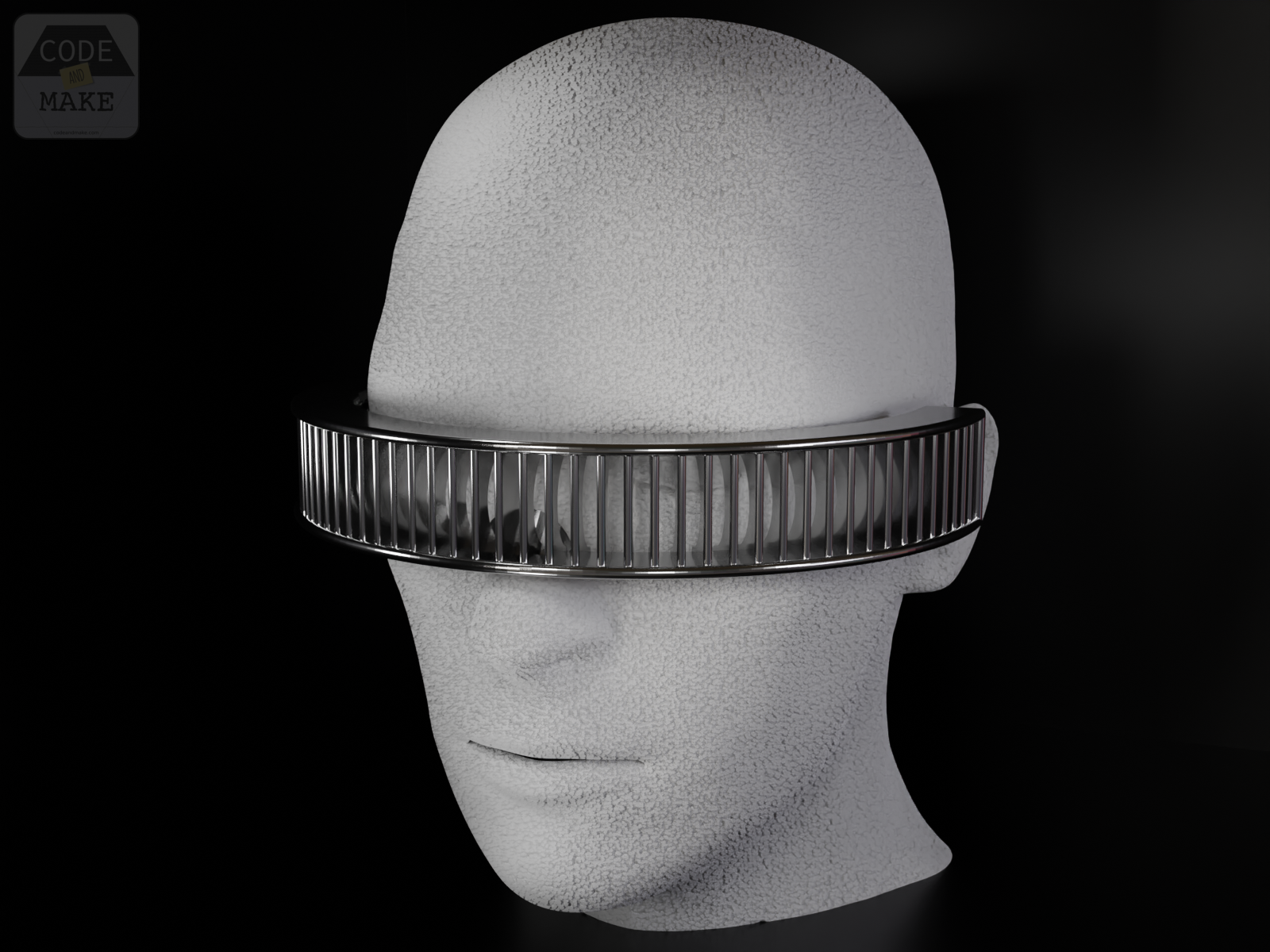

It's party time all the time with these awesome, 3D printable, blade glasses!

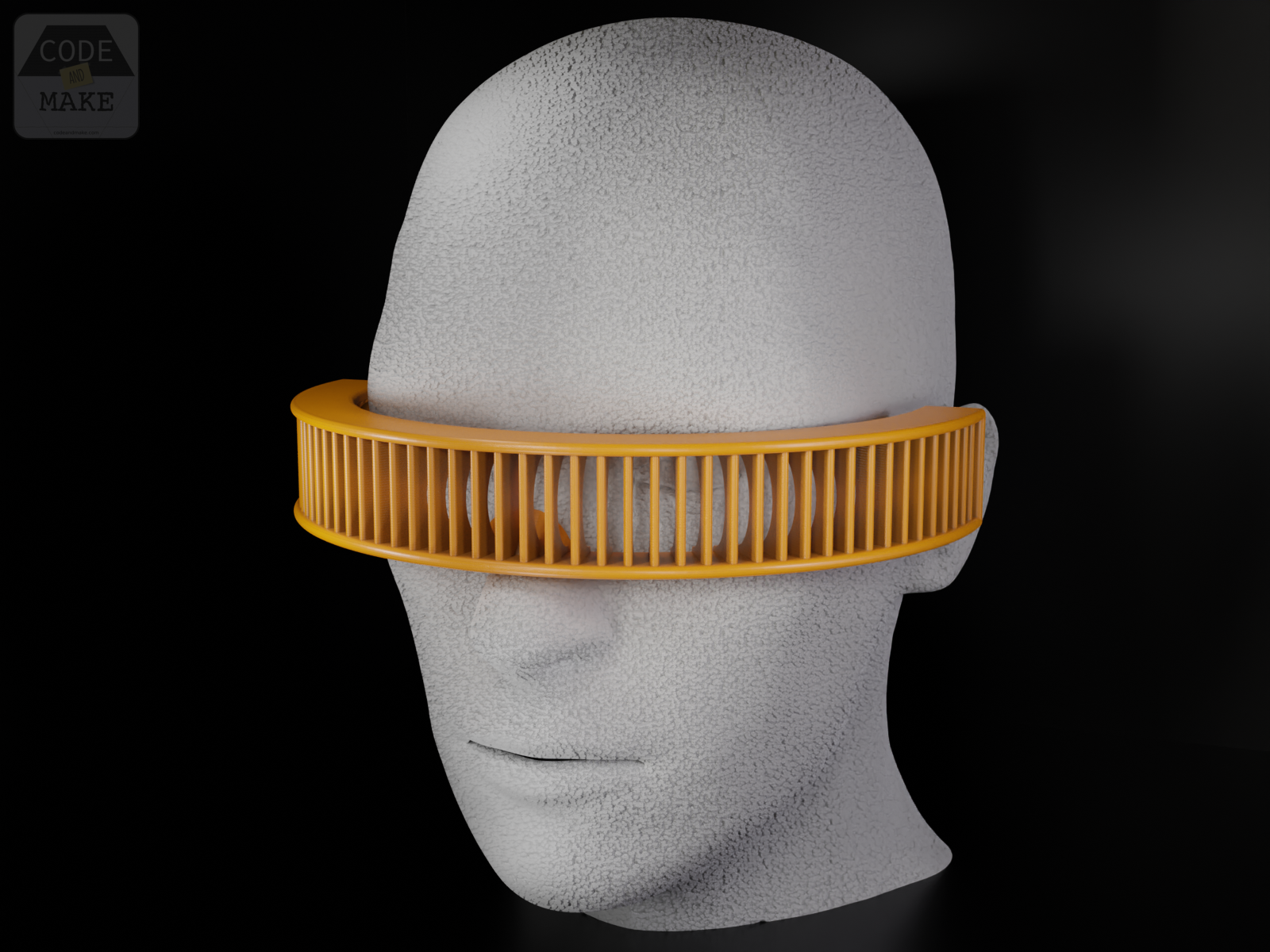

This design is fully customisable, allowing you to adjust the design for the perfect fit.

It even has support dual extruder printers, with its built-in part splitting features.

Design

Many weeks have gone into developing and refining this design. We 3D printed lots of prototypes to optimise the design for the best field of view, minimal overhangs and high printability.

It is designed for printing as a single part; to both increase strength and remove the need for assembly.

We've also provided lots of Customizer options to help you achieve the perfect fit.

Customizer Options

We recommend you use OpenSCAD to customize this design.

This design has the following Customizer options:

Head

Head_Diameter - Diameter of the main head piece

Nose

Nose_Diameter_Top - Diameter of the top of the nose pieceNose_Diameter_Bottom - Diameter of the bottom of the nose pieceNose_Angle - Angle of nose piece (approximate)Nose_Offset - Offset along Y axis (forwards/backwards)

Arms

Arm_Height - Height of the arm materialArm_Top_Length - Length of arm (excluding ear piece)Arm_Ear_Top_Angle - Angle of ear piece (determines length)Arm_Ear_Radius - Radius of ear piece (determines length)Arm_Ear_Side_Rotation_Angle - Side rotation of ear piece (inwards/outwards)Arm_Vertical_Offset_Percent - Vertical offset of ear piece (as percentage of available height)

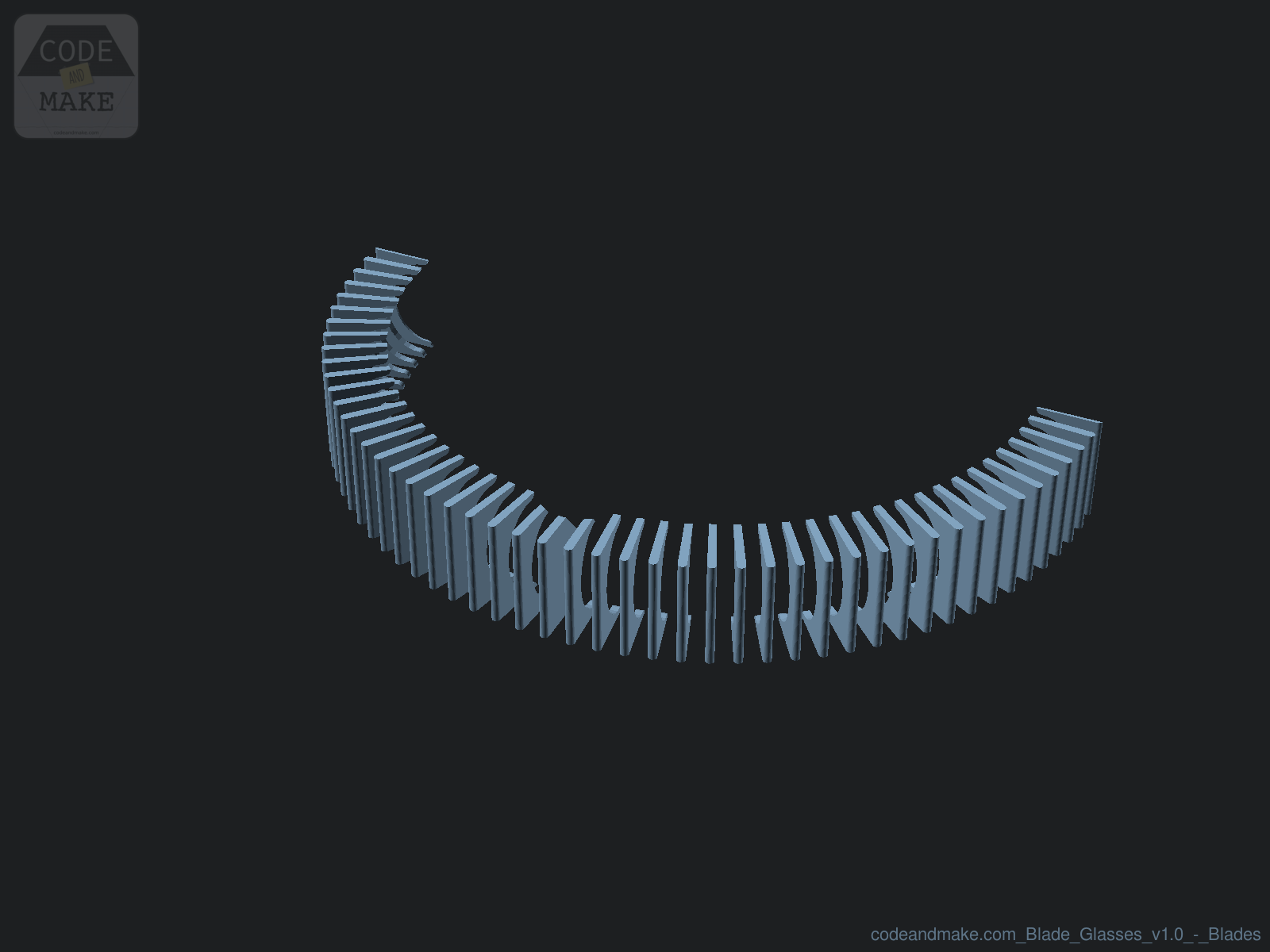

Blades

Blade_Height - Height of bladesBlade_Length - Length of bladesBlade_Diameter - Diameter (width) of blades (at outside)Blade_Gap - Gap between the blades (at outside)

Other

Material_Thickness - Overall thickness of material (except blades)

Parts

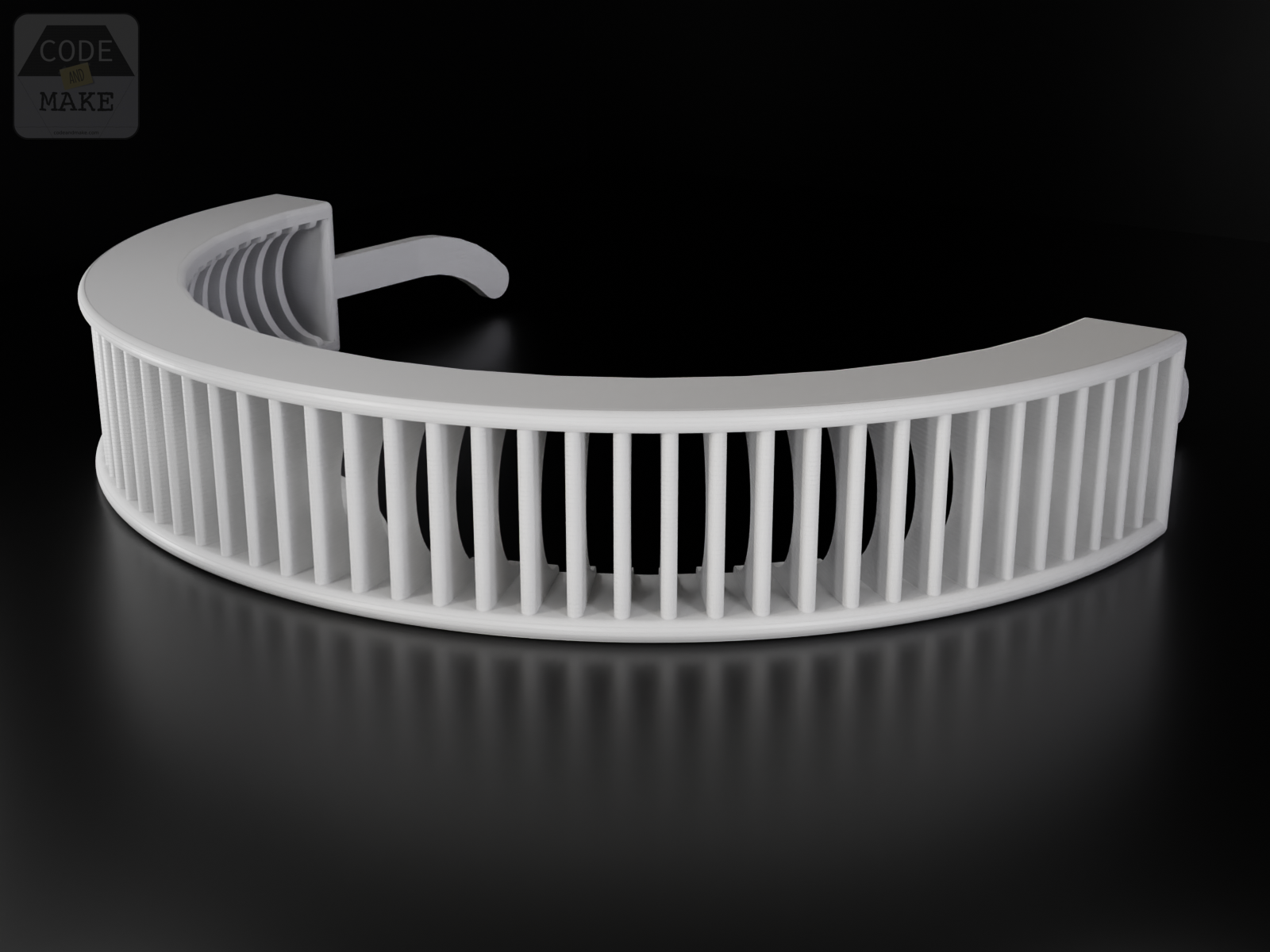

Frame - Generate the frame section?Blades - Generate the blades?

Preview

Show_Blades_In_Preview - Show blades in preview (set to 'No' to improve performance)Show_High_Detail_In_Preview - Show high detail in preview (not recommended when Show_Blades_In_Preview is set to 'Yes')

Design Considerations

This design is quite resource intensive for OpenSCAD to process. A high polygon count is used for rendering, so rendering can take a couple of minutes. To improve performance, the polygon count is reduced whilst in preview mode. Additionally, some details are not show in preview mode to improve preview performance even further. You can improve preview performance even further by disabling the Show_Blades_In_Preview setting.

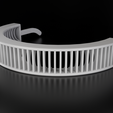

The sample .STL included with this project is an export of the default options and is included for demonstration purposes only. Due to variations in head and nose shapes, this .SCAD file includes a number of customizable features for you to adjust for maximum comfort. We strongly recommend taking the time to customise the design using the .SCAD file (using the Customizer feature in OpenSCAD) rather than trying to scale the included .STL file in your slicer.

Whilst the default Customizer settings should be a good starting point, we suggest taking head measurements and performing a test print to help you refine the Customizer settings for your final print. Remember to save a preset in OpenSCAD, so that you can easily recall the Customizer settings you used.

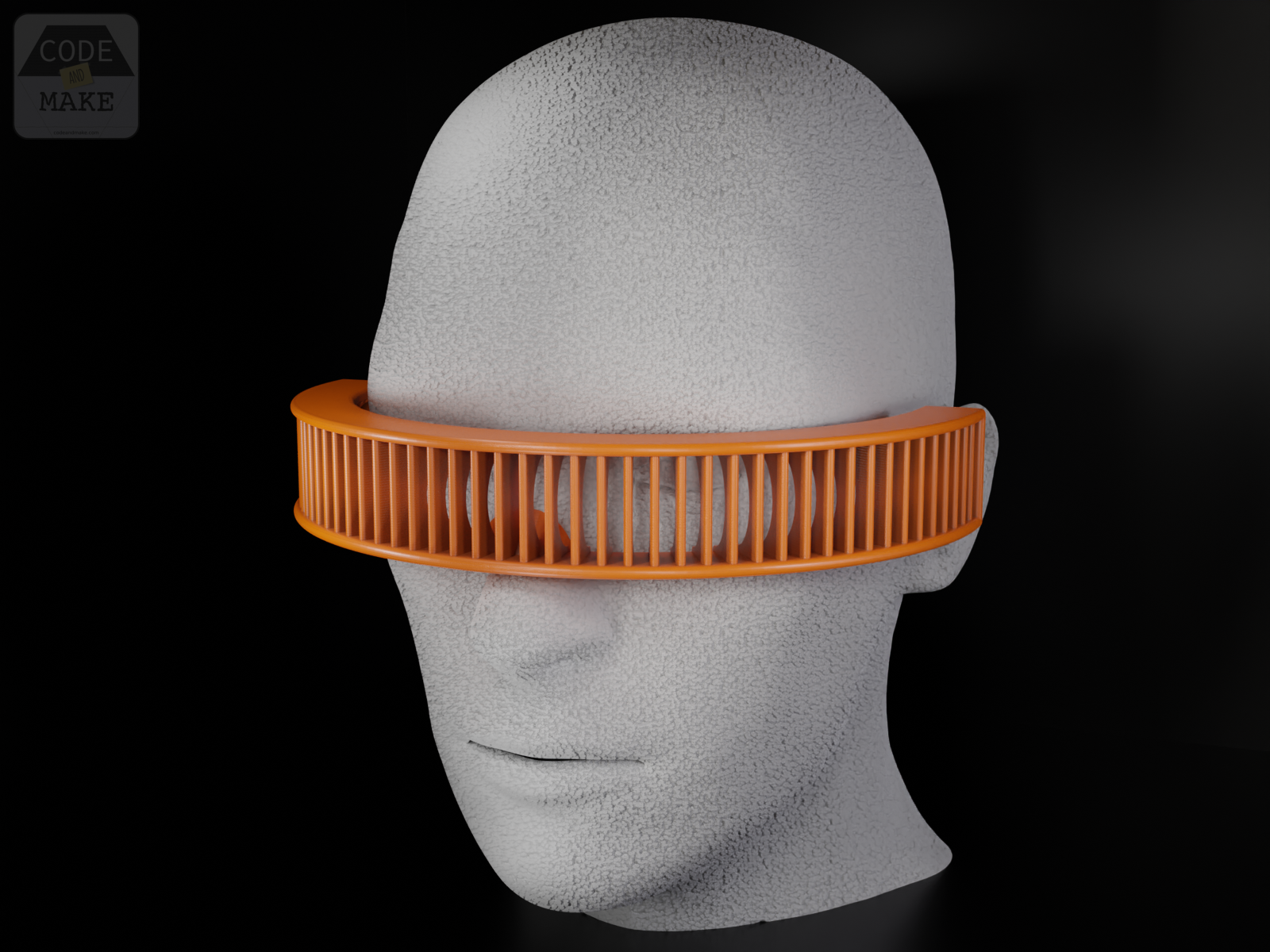

You should prefer thin and close blades, over wider and more spaced out blades. This generally looks better, it should improve your view and it should also increase the final print quality because it reduces the size of the overhang between the blades. However, thinner blades are more prone to breaking whilst printing, so you may need to adjust your slicer settings to reduce the chance of that happening.

Material

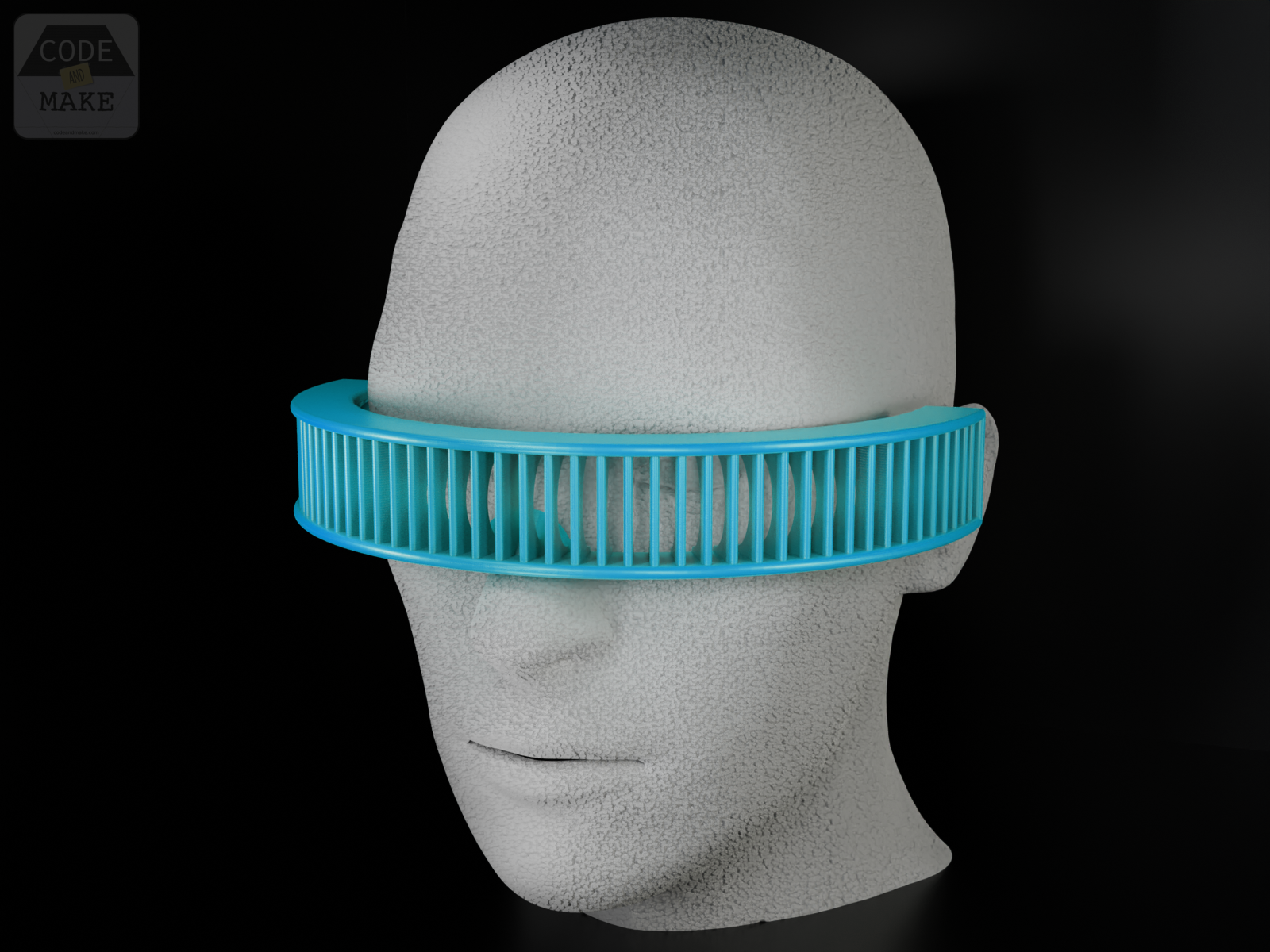

This design is perfect for printing in many filaments, including PLA, PETG and ABS.

Versions

- 1.3 (9 Apr 2021) - Updated license text

- 1.2 (8 Apr 2021) - Added license text

- 1.1 (4 Apr 2021) - Fixed Customizer typos

- 1.0 (3 Apr 2021) - Initial version

Printing

Recommended slicer settings:

- Resolution: 0.1mm - 0.2mm

- Infill: ~20% recommended.

- Supports: Should only be required for the arms.

- Rafts: Not required, unless you experience adhesion issues.

Supports should only be required for the arms. You should select the 'Touching Buildplate' (or equivalent) supports option in your slicer. You should not require supports for the blades.

If your 3D printer's extruder catches and breaks the blades, you may need to reduce the flow or consider using your slicer's 'Z Hop When Retracted' (or equivalent) option. Additionally, you may need to reduce the print speed and adjust cooling settings.

We recommend printing this as it is oriented in OpenSCAD (upside down). This will ensure any unremoved support material is restricted to the top of the arms and that it will not irritate your ears.

Dual Extrusion

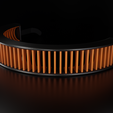

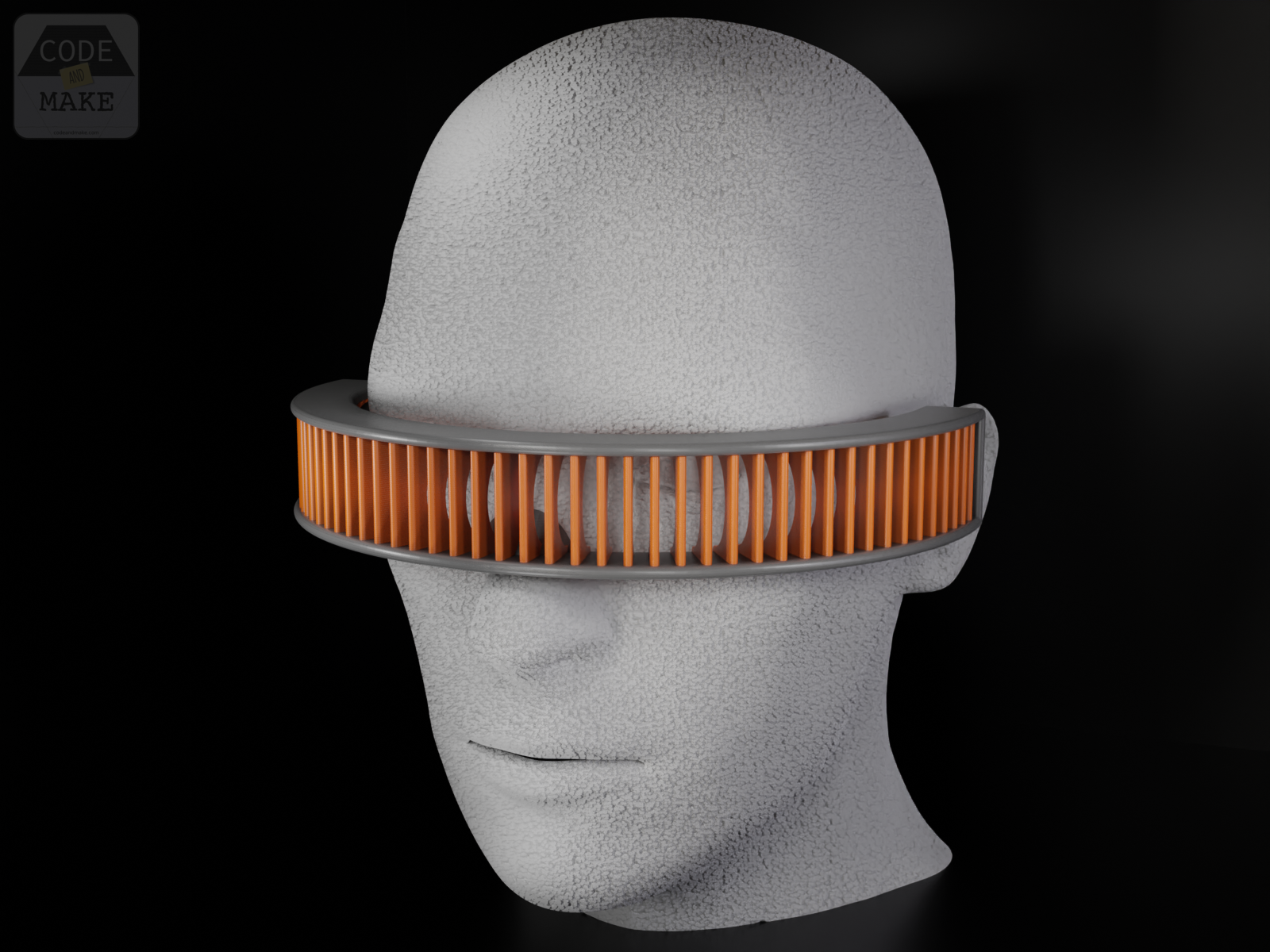

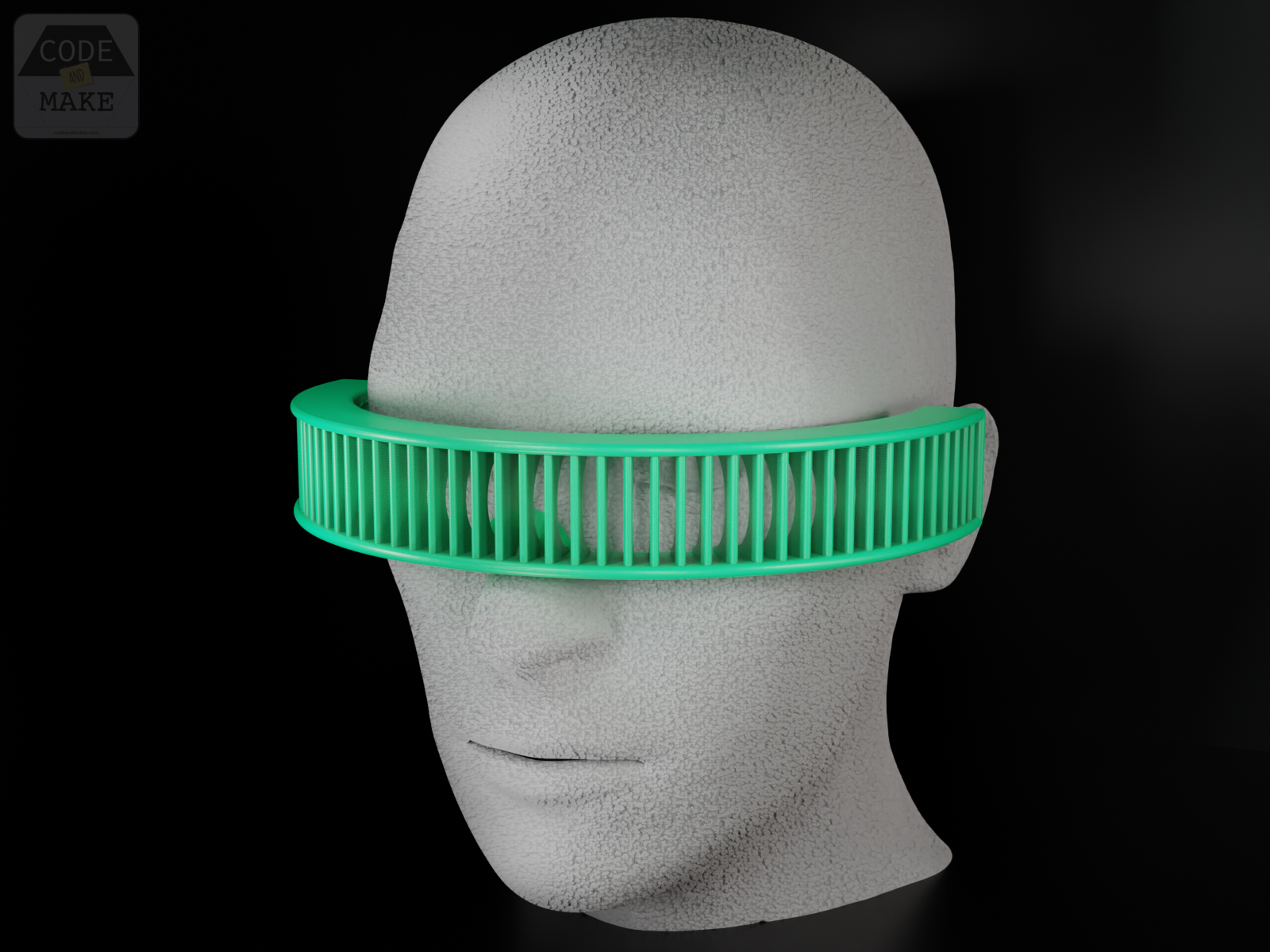

This design can be printed in two colors on a dual-extrusion printer.

For a dual extrusion print, you will need to export the 'frame' and 'blades' separately (using the Frame and Blades options under the 'Parts' tab). The two parts can then be combined and configured for dual extrusion printing in your slicer.

Finishing

This design should require a minimal amount finishing, only requiring a light sanding on the tops of the arms after the support material has been removed.

For maximum comfort, we suggest using a small amount of self-adhesive foam inside the nose section.

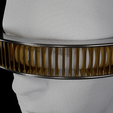

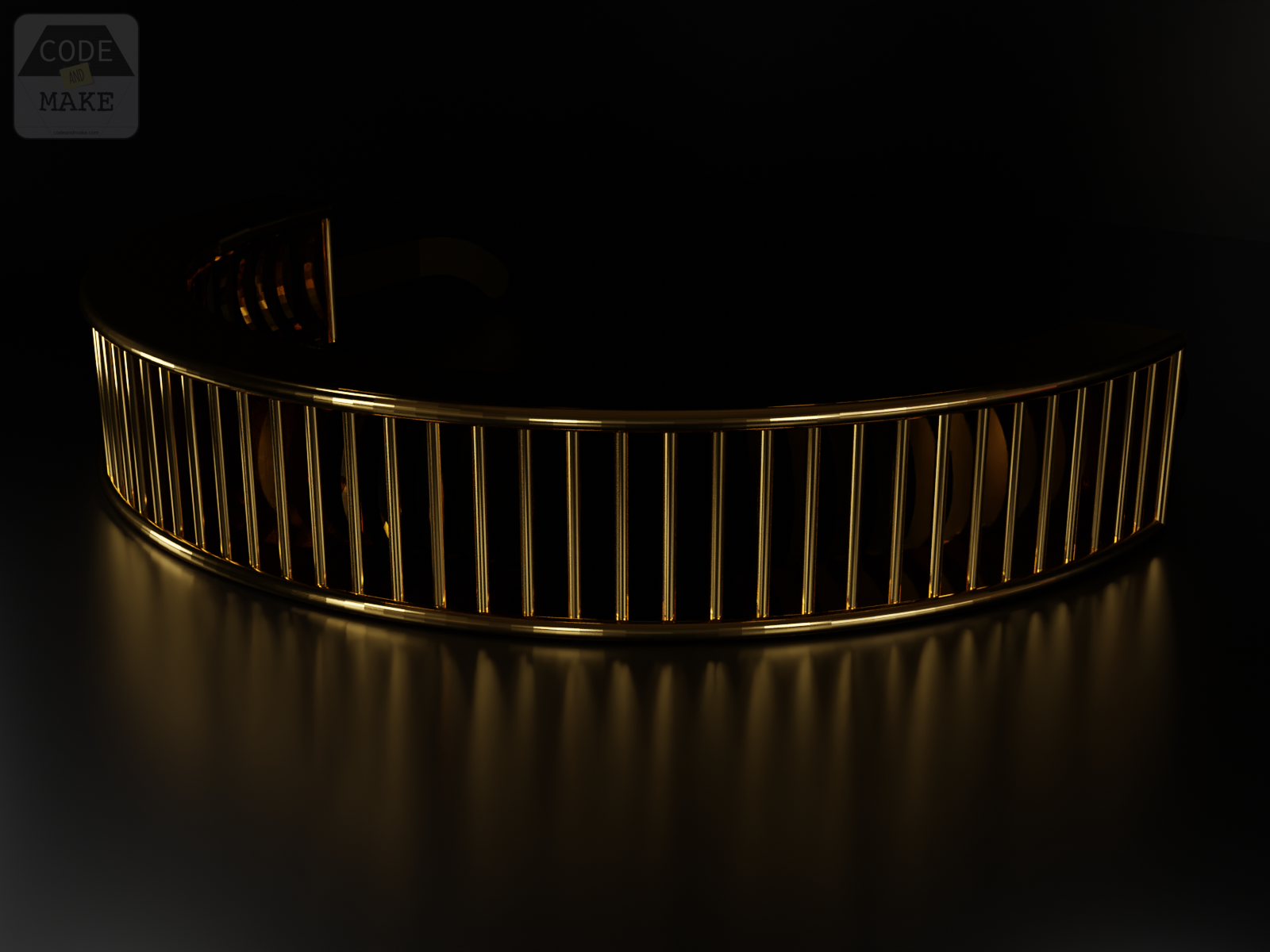

This design looks awesome with a metallic or mirrored finish. So why not consider painting it?

If you'd like dual colors but you don't have a dual extruder, you can print it with the filament color you want for the blades, cover the blades with masking tape and then paint the frame.

License

The "Blade Glasses" files are licensed under the Standard Royalty Free license by Code and Make.

/https://fbi.cults3d.com/uploaders/16502974/illustration-file/667f3a9d-fea2-4df8-970a-8334dfeebe8f/codeandmake.com_Blade_Glasses_v1.0.gif)