Solex 32 carburetor for VW Fusca!!!!

instagram @scalla3d

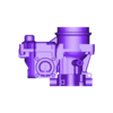

After a great repercussion on the internet of a VW Brasília running with a printed carburetor, which was initially made to demonstrate the possibilities of using 3D printing and divulgation of our work, it is as a form of retribution that I come to make publicly available the 3D model of the Solex 32 Carburetor in the video.

This carburetor is the one that equips the entire VW air line when equipped with dual carburetion.

This project was born from a curiosity to know if a carburetor made of plastic and printed on a bench printer could really make an engine work. It was developed through reverse engineering based on a Brosol Solex H32/34 carburetor.

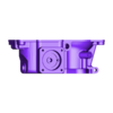

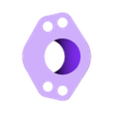

The model has all the main components for the carburetor assembly but depends on some other items that can be easily found in any car part or ferro-steel. The suggestion would be to use the original carburetor shaft, diaphragm, giclage, injector tube.

The parts are interchangeable between the real model and the printed one, so you can use the metal body of the borbolette and the other one printed for example.

The idea of making this project public is natural due to the complexity of making the piece thermally and chemically stable, as many printing materials would not resist the operating temperature or the chemical aggression of gasoline/alcohol.

I understand the rigor required to validate a part so vital to the operation of an engine, which could only be possible after thousands of kilometers of testing and I have no ambition to believe that we will find the best solution to all the challenges ahead.

Thus, with the help of a maker community, passionate about mechanics, we will be able to find the best specification to achieve, who knows one day, to use such a part in our cars. After all, many heads think better than one.

To all who have progress on the project, I ask you to share with the community through comments or makes. There is nothing in this sense similar in complexity developed on the internet, and it is with great pride that I say that the first functional printed carburetor is Brazilian!

Many parts of a modern engine are already plastic, and I have no doubt that even with so many technical challenges, in the near future we will have all the solutions and will be able to manufacture any carburetor model at home, including new ones that would only be possible with the help of 3D printing.

The proposed carburetor is functional, as long as the printing instructions and adjustments described below are respected. It can be printed for test purposes or even for didactic purposes for those who want to understand the operation and the mechanical concepts involved.

Main challenges:

Sealing (post-printing finishing)

Thermal stability (material selection)

Chemical Stability (material selection)

Results obtained so far:

The ABS material does not withstand the attack of gasoline.

The PETG material showed excellent chemical and thermal stability in the short term, but after a few days it begins to crack, probably due to the reaction with gasoline.

PLA is the material that behaves best with gasoline, but has a low melting temperature.

No test with ethanol has been performed so far.

In relation to the leakage, no leakage was found between layers when 4 perimeters were used. The use of threaded trava thread in the tank bushing, inlet tube and valve also guarantees a good sealing.

/https://fbi.cults3d.com/uploaders/18010339/illustration-file/6a418eee-ed81-4731-bc9a-05d15c8aa984/4.jpg)