]] Feel free to use parts from this as you please, but if you want a lightweight extrusion printer you should build the flexMendel by dkennel instead. [[

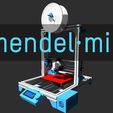

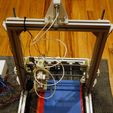

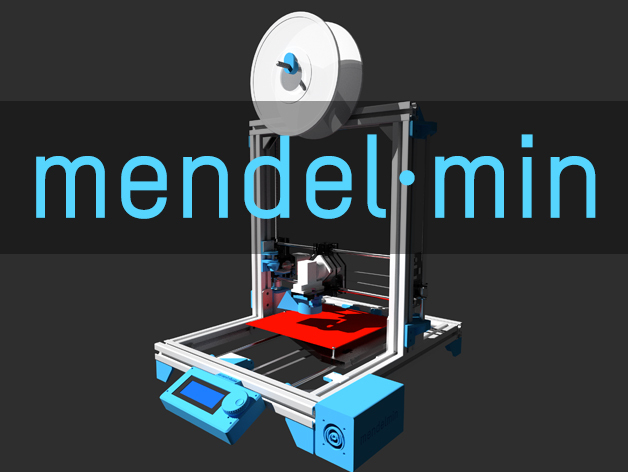

After a long hiatus, this is the fully functional and tested Mendelmin 1.0. This is a solid upgrade for someone still using a Prusa i2 with a MakerGear Plastruder, who has access to a laser cutter. This printer has 230mm of vertical Z height, and thanks to an aluminum extrusion frame with steel bracing brackets, it is very rigid and strong.

It currently uses a combination of lasercut and 3d printed parts. The original design used only 3d printed parts, but I was unable to get the precision and strength I wanted from the 3D printed Z and X carriages, which ended up being over-constrained. This problem has been solved with laser cutting. Pieces are cut from 1/4" acrylic plastic, which can be done on a fairly low-power laser engraver (I used a Trotec 100).

Lasercut pieces slot together and are bonded with acrylic solvent.

Changelog:

2/17/2015

Replaced all parts on the X and Z carriages with components designed to be laser-cut.

.

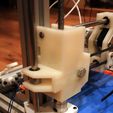

Added extruder fan duct

.

Rotated Plastruder assembly 90 degrees for more X distance.

.

Initial testing: works 100%!

New RAMPS + Taurino Power (Arduino Mega 2560) case added to 0.1.5. Designed to be printed in flat pieces, to minimize print time (z is by far the slowest axis).

.

RRD Smart LCD controller case added to 0.1.4, mountable on any horizontal rail.

.

Z endstop mount retooled! Included in 0.1.3

http://www.thingiverse.com/thing:186588

BOM-in-progress:

https://docs.google.com/spreadsheet/ccc?key=0AqZcZ8jLY5V_dHpOcUQ2VmlWTU1pZ1JnSDJwR1VxbWc

.

The X carriage has been completely redesigned specifically for the MakerGear Stepper Plastruder. If you have a different extruder, you will have to use a different X carriage. The X motor and idler ends have also been retooled to ride on Z smooth rods, and to use two nuts on the Z threaded rods to reduce Z wobble. Also included is a low-profile fan duct designed specifically for this X carriage, as well as a new, very robust printed spool holder.

.

Metal brackets should be used for strength, which should give an improvement in rigidity over the Aluminum Mendel (or the Adapto, which uses printed brackets). These parts, along with the aluminum extrusions, can be sourced from Misumi USA.

.

This is still a WIP, some small parts have not been added.

In progress:

1) 3d printable versions of the laser-cut components.

2) Laser-cut versions of 3d printable components

3) Updating BOM

4) Compatibility mount for other more common extruders (Bowden-type especially).

5) Design camera mount for the Logitech C270/C320 webcam.

6) Z probe addon

.

Recommended:

M5 T-slot nut substitute (don't use for major structural components, but great for addons): http://www.thingiverse.com/thing:28788

Credit goes to Crota for designing this mount, which I have modified for my X-carriage: http://www.thingiverse.com/thing:182889

Nateplate (the Y plate here is a poor reproduction of this idea): http://www.robosprout.com/hardware/aluminum-beds/nathan7-s-prusa-bottom-plate.html

Fan guard: http://www.thingiverse.com/make:49798

Further reduce spool friction: http://www.thingiverse.com/thing:148454

Printable dial indicator: http://www.thingiverse.com/thing:155464

.

Based on the awesome Aluminum Mendel by dkennell (http://www.thingiverse.com/thing:16076).